Shearing type steel truss connection beam with friction damper for quick recovery after earthquake

A friction damper and rapid recovery technology, which is applied to truss beams, truss structures, shockproof, etc., can solve problems such as difficult repairs and achieve low repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

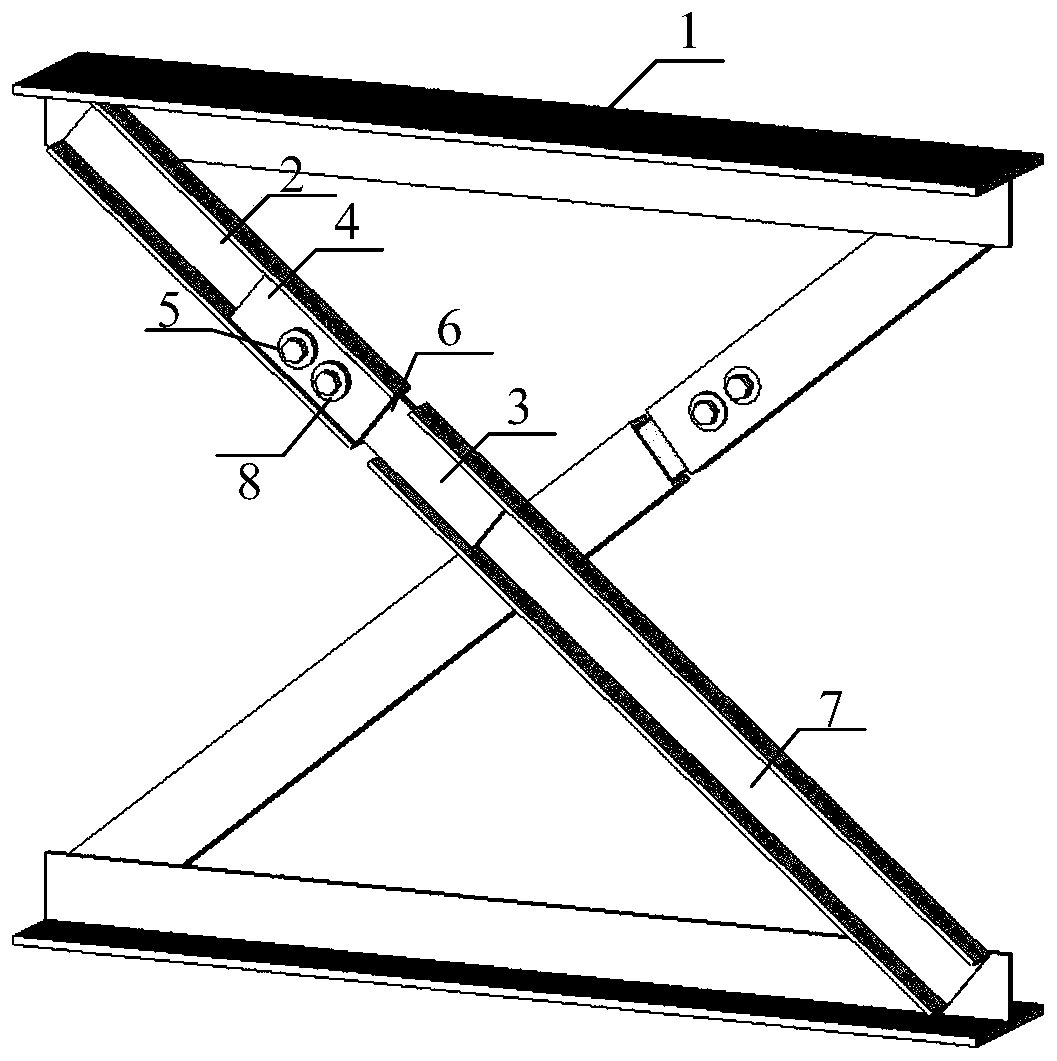

[0022] The invention discloses a fast recovery shear steel truss connecting beam with a friction damper after an earthquake, comprising a friction damper, a chord 1 and a diagonal web.

[0023] Such as figure 1 As shown, the diagonal rod includes the diagonal rod A2 and the diagonal rod B7, and the friction damper connects the diagonal rod A2 and the diagonal rod B7 to form a diagonal rod; the two diagonal rods are cross-fixed Between the two chords 1, the two chords 1 are kept parallel; the upper ends of the two oblique webs A2 are respectively welded to the upper chord 1, and the lower ends of the two oblique webs B7 are respectively welded to the lower chord 1 on.

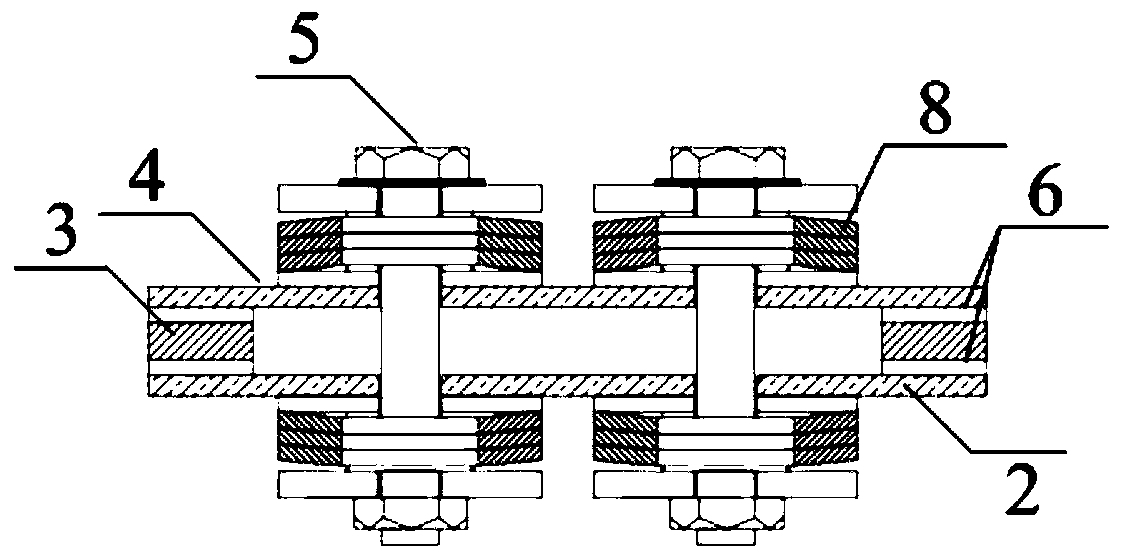

[0024] The friction damper is installed at the web at the bottom of the diagonal web bar A2, and the friction damper includes a friction main board 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com