Production technology of rabbit velvet, nylon and viscose blended yarn

A technology of blended yarn and production process, which is applied in the field of yarn, can solve problems such as difficult carding and easy knotting, and achieve the effects of improving quality, cohesion, and anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

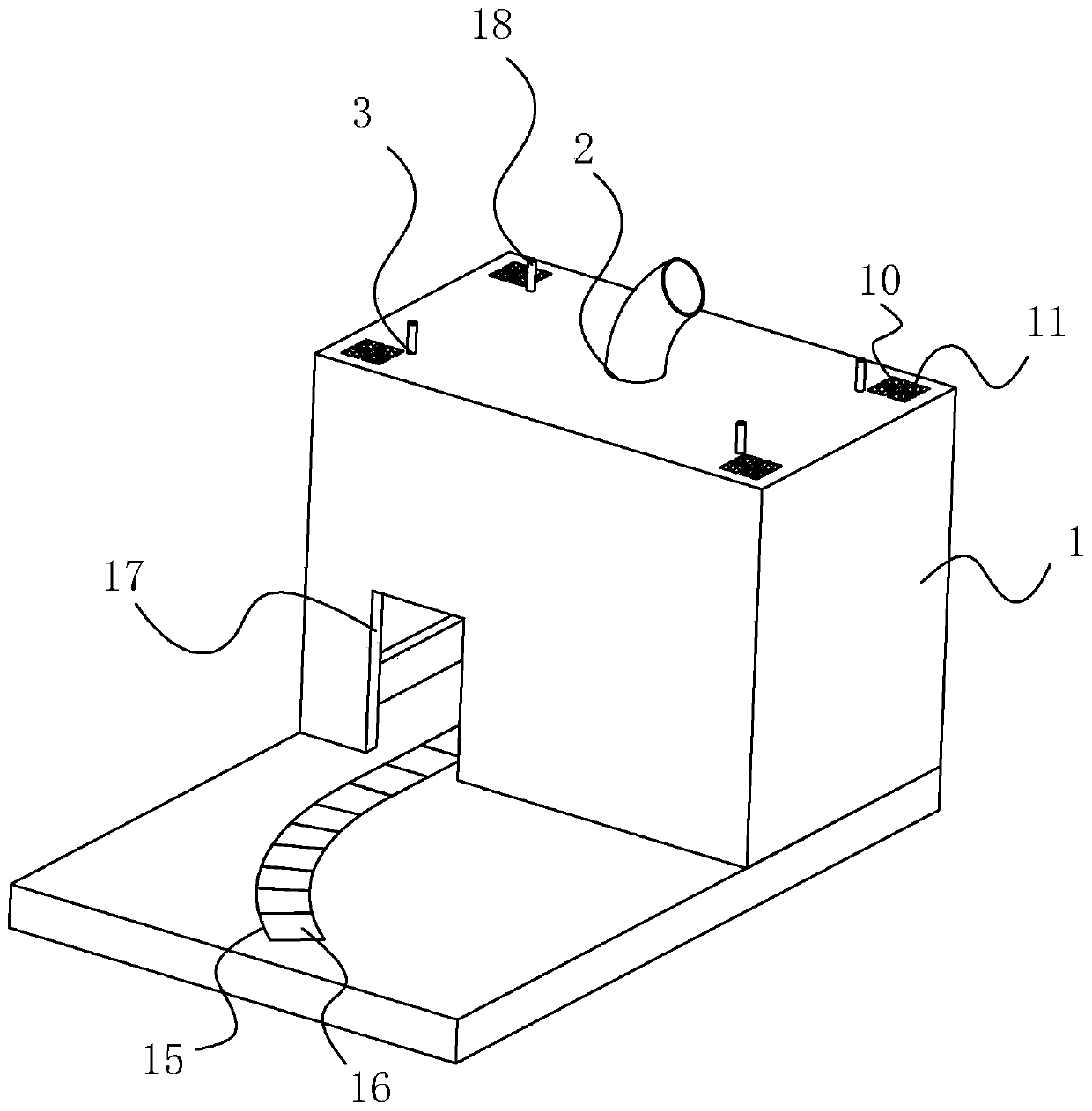

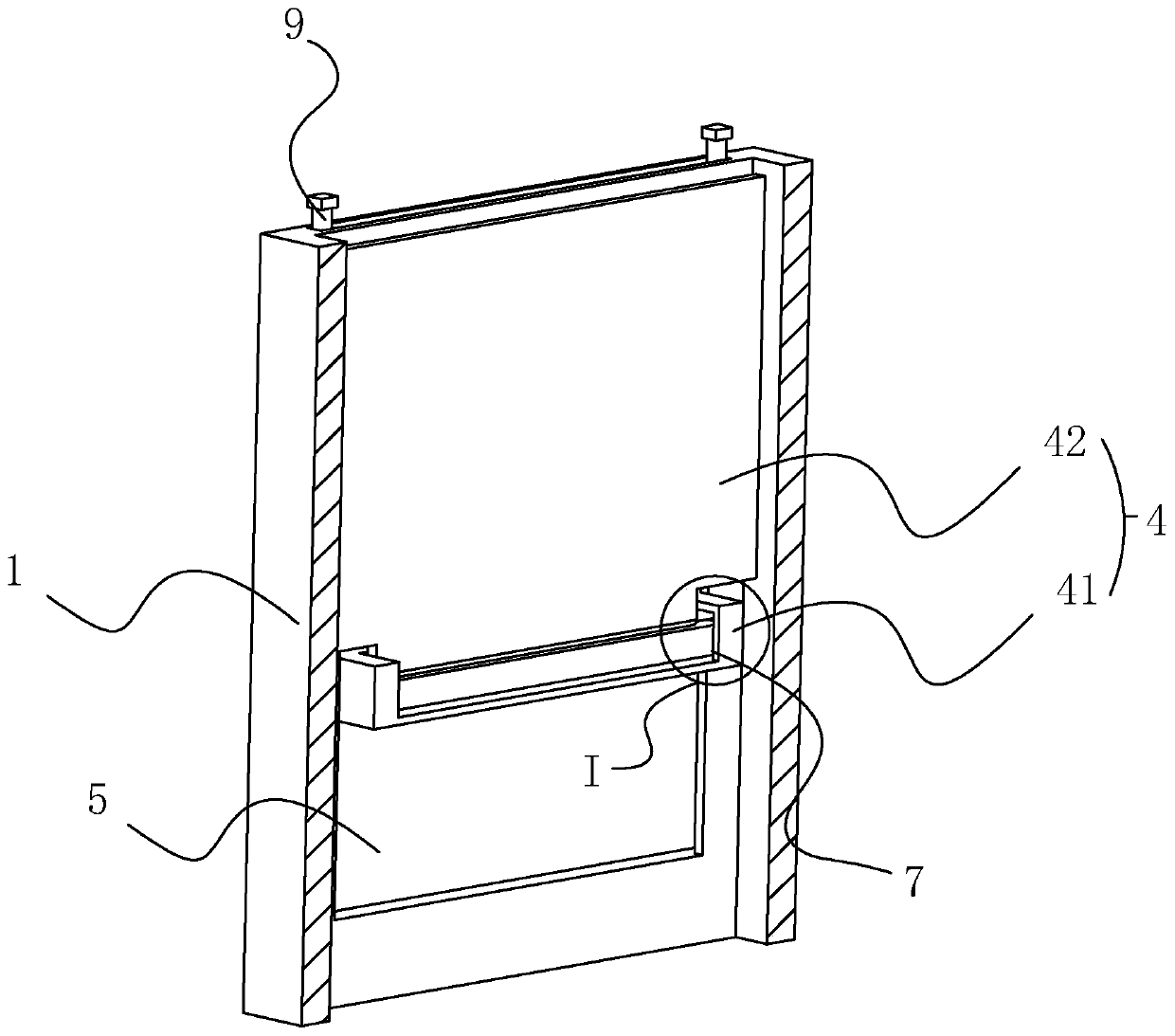

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] A kind of production technology of rabbit down nylon viscose blended yarn, comprises the steps:

[0037] Step A: material selection, select rabbit down, nylon, viscose three kinds of raw fibers, according to the mass parts, rabbit down 10-15 parts, nylon 20-25 parts, viscose 30-35 parts; step B: initial and Wool, according to the ratio requirements of the three raw materials, the raw material fibers are sequentially broken up by the wool machine, and transported to the wool warehouse. In the wool warehouse, two layers of rabbit down, one layer of nylon or viscose, The superposition of two layers of rabbit down is piled up, and the hair blending agent is sprayed between each two layers of rabbit down, and the hair is stuffed for 8-10 hours, and the hair blending agent includes 60-70 parts by mass of water, With 2-3 parts of crude oil and 1.15-1.5 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com