Wire rod surface phosphated residue treatment method

A surface phosphating and slag treatment technology, which is applied in the direction of metal material coating process, can solve the problems of affecting the phosphating effect of metal materials, waste, and increasing the cost of phosphating slag treatment, so as to reduce the production time of pickling and save The effect of processing costs and improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0030] A method for treating phosphating slag on the surface of a wire rod, comprising the steps of:

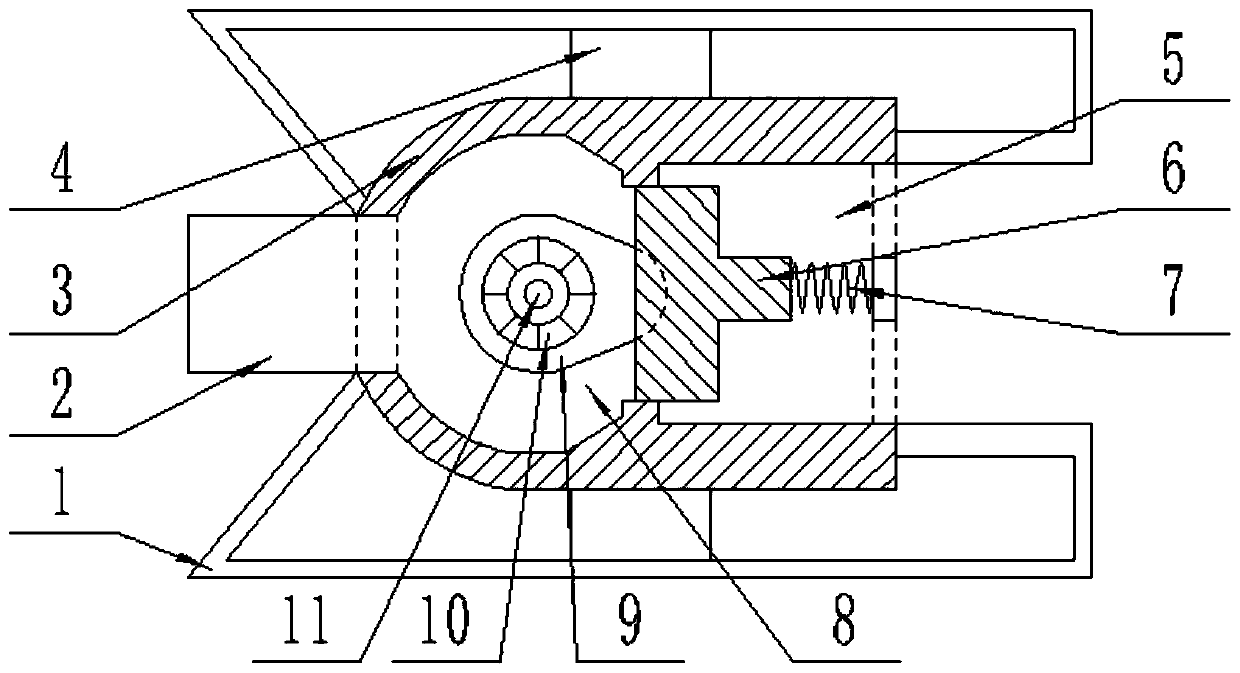

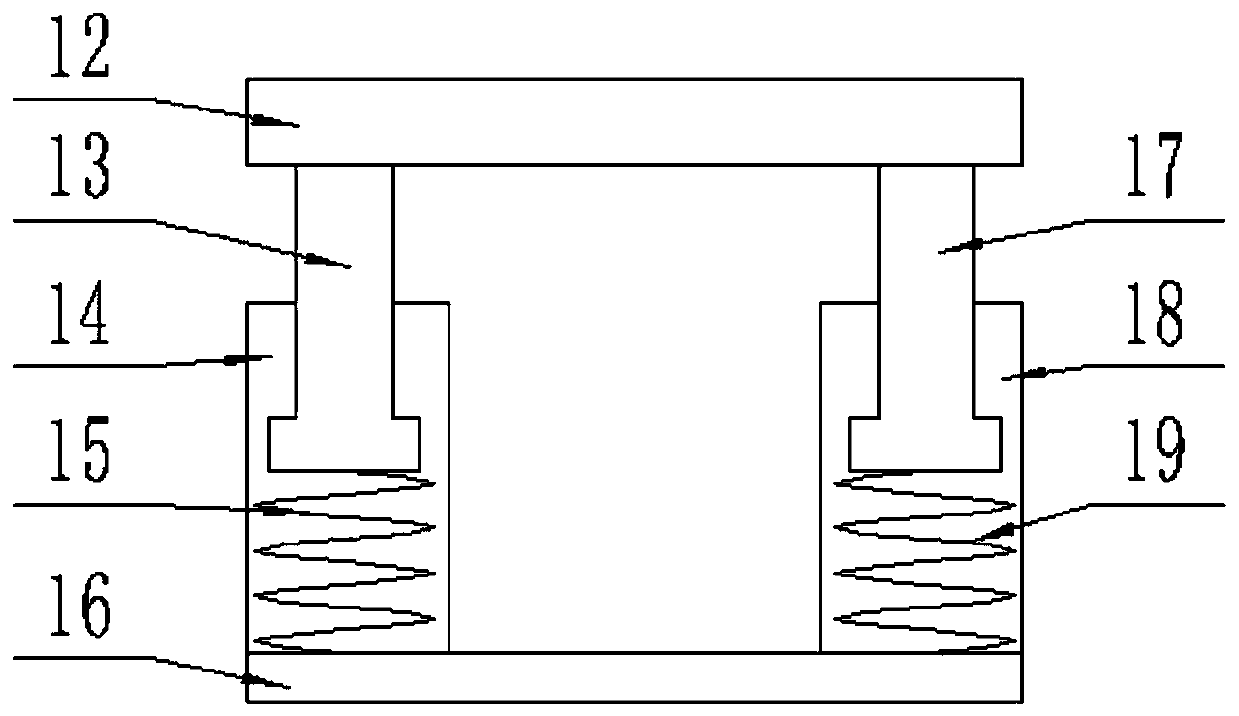

[0031] A. The phosphating solution in the pickling and phosphating tank is pumped into the centrifuge through the cam pump;

[0032] B. The phosphating solution is in the centrifuge, and the phosphating slag in the phosphating solution is separated through the centrifugal separation function of the centrifuge;

[0033] C, the phosphating slag obtained in step B is unloaded in the phosphating slag carrying pier bag;

[0034] D. Return the phosphating solution separated in step B to the pickling phosphating tank through the pipeline.

[0035] In order to work better, there are two pickling and phosphating tanks in the step A, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com