Alloy material for brake disc of high-speed heavy haul train, preparation method thereof and brake disc

A technology of alloy materials and heavy-duty trains, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems that restrict the development of aluminum alloy brake discs, the limited heat insulation performance of the wear-resistant layer, and affect the safety of trains, etc. , to achieve the effects of small thermal impact, good load-bearing effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

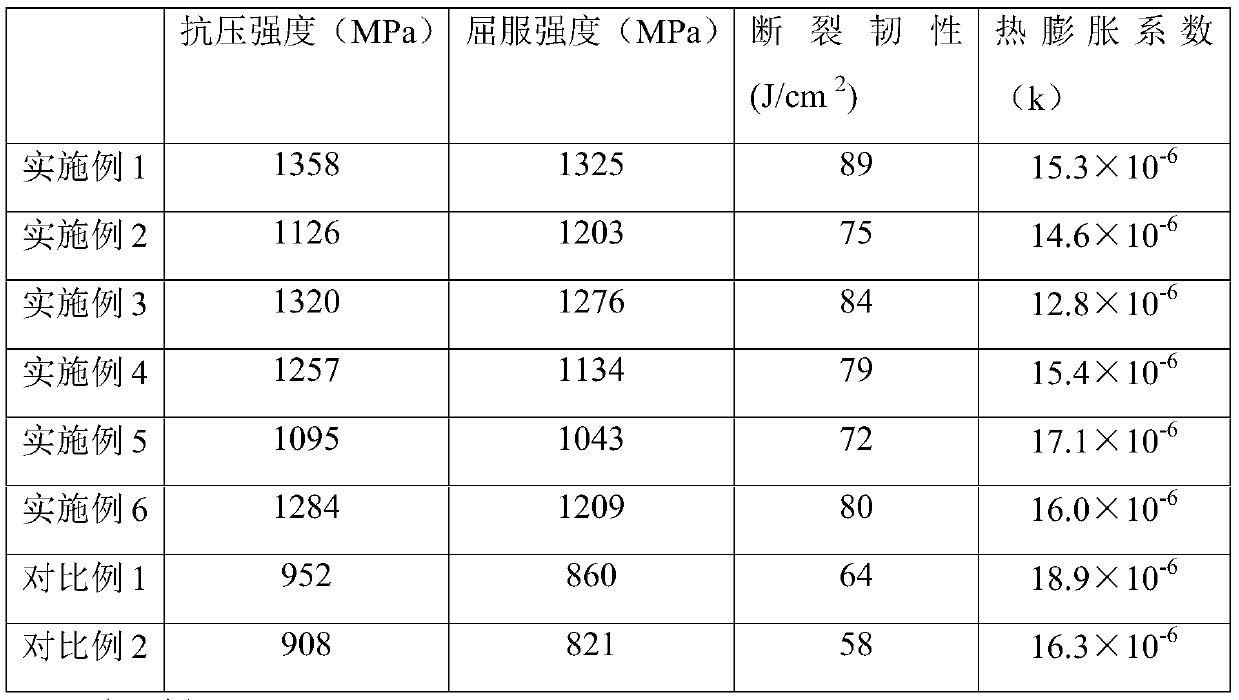

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing alloy materials for brake discs of high-speed and heavy-duty trains, which specifically includes the following steps:

[0033] S1. Melting: heat Al to a liquid state and add Ti, Cu, Mn, and V master alloys in proportion at 850°C. The specific mass percentages are as follows: Ti: 3%, Cu: 2%, Mn: 0.3% , V: 1%, the balance is Al, stir continuously to form a liquid metal with uniform composition, and let it stand for 20 minutes;

[0034] S2. Refining: Into the liquid metal obtained in step S1, feed anhydrous high-purity nitrogen with a purity of 99.9% for refining for 60 minutes, add a slagging agent to the surface of the liquid metal, and remove slag after standing for 15 minutes to obtain an alloy melt;

[0035] S3. Spray forming: use aluminum alloy spray forming equipment to spray the alloy melt obtained in step S2 to prepare alloy materials for brake discs of high-speed and heavy-duty trains. The pressure of nitrogen is 2...

Embodiment 2

[0037] This embodiment provides a method for preparing alloy materials for brake discs of high-speed and heavy-duty trains, which specifically includes the following steps:

[0038] S1. Melting: heat Al to a liquid state and add Ti, Cu, Mn, and V master alloys in proportion at 800°C. The specific mass percentages are as follows: Ti: 5%, Cu: 4%, Mn: 0.5% , V: 1.2%, the balance is Al, stir continuously to form a liquid metal with uniform composition, and let it stand for 15 minutes;

[0039] S2. Refining: Into the liquid metal obtained in step S1, feed anhydrous high-purity nitrogen with a purity of 99.9% for refining for 45 minutes, add a slagging agent to the surface of the liquid metal, and remove slag after standing for 25 minutes to obtain an alloy melt;

[0040] S3. Spray forming: use aluminum alloy spray forming equipment to carry out spray forming to the alloy melt obtained in step S2, prepare the alloy material for brake disc of high-speed heavy-duty train, the pressur...

Embodiment 3

[0042] This embodiment provides a method for preparing alloy materials for brake discs of high-speed and heavy-duty trains, which specifically includes the following steps:

[0043] S1. Melting: heat Al to a liquid state and add Ti, Cu, Mn, and V master alloys in proportion at 750°C. The specific mass percentages are as follows: Ti: 2%, Cu: 4%, Mn: 0.8% , V: 1.5%, the balance is Al, stir continuously to form a liquid metal with uniform composition, and let it stand for 15 minutes;

[0044] S2. Refining: Pass into the liquid metal obtained in step S1 anhydrous high-purity nitrogen with a purity of 99.9% for refining, the time is 40 minutes, add a slag-removing agent to the surface of the liquid metal, and remove the slag after standing for 20 minutes to obtain an alloy melt;

[0045] S3. Spray forming: use aluminum alloy spray forming equipment to spray the alloy melt obtained in step S2 to prepare alloy materials for brake discs of high-speed and heavy-duty trains. The pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com