Pressure type blast furnace red slag waste heat recycling system and method

A waste heat recovery and pressure technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of water volume, heat energy waste, environmental pollution, etc., and achieve the effect of reducing consumption, easy transformation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

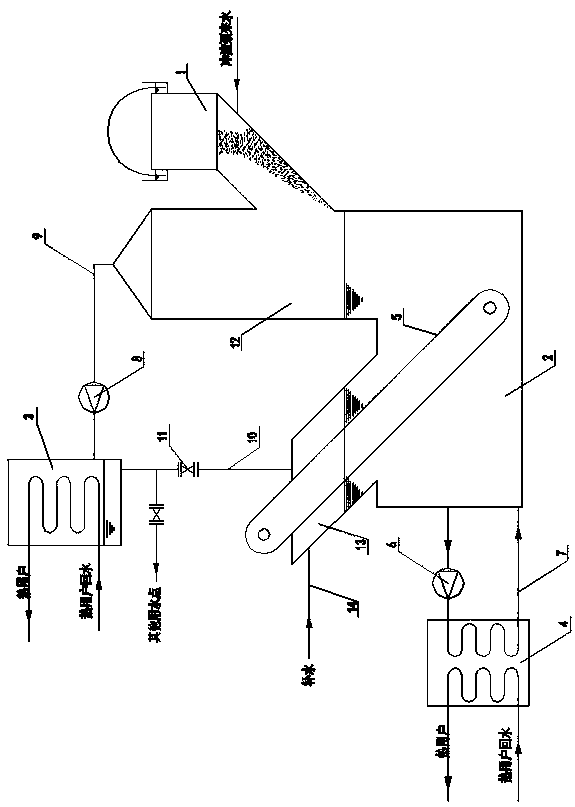

[0022] Such as figure 1 As shown, a pressure-type blast furnace red slag waste heat recovery system includes at least a slag flushing unit, a water vapor condensation heat exchange unit, and a slag flushing water heat exchange unit; the bottom of the slag flushing unit is connected to the slag flushing water heat exchange unit through a pipeline valve ; The top of the slag flushing unit is connected with the water vapor condensation heat exchange unit through a pipeline valve.

[0023] The slag flushing unit includes a red slag storage bin 1, a slag flushing pool 2, a slag discharge mechanism 5 and a water vapor outlet pipe 9; the slag flushing pool 2 upper part of the slag flushing unit includes two V-shaped structures, one of which is formed by a V The glyph structure separately forms a water vapor escape chamber 12 and a slag discharge chamber 13. One end of the other V-shaped channel is connected to the red slag storage bin 1, and the other end forms a water vapor escape c...

Embodiment 2

[0035] On the basis of Embodiment 1, a liquid level detection device (not shown in the figure) can be added in the slag washing tank 2, which can be interlocked with the water supply pipe 14 valve to control the valve switch, so as to effectively ensure that the water level of the slag washing tank 2 is sufficient to prevent water vapor from escaping. The slag discharge chamber 12 and the slag discharge chamber 13 prevent the water vapor produced by slag flushing from escaping from the slag discharge chamber 13.

[0036] The invention can fully recover waste heat, ensure no leakage of harmful gas, recover a large amount of water vapor, and reduce water consumption. The structure of the system is simple, and it is convenient to carry out the transformation of the slag flushing treatment system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com