Method for industrially producing mequitazine

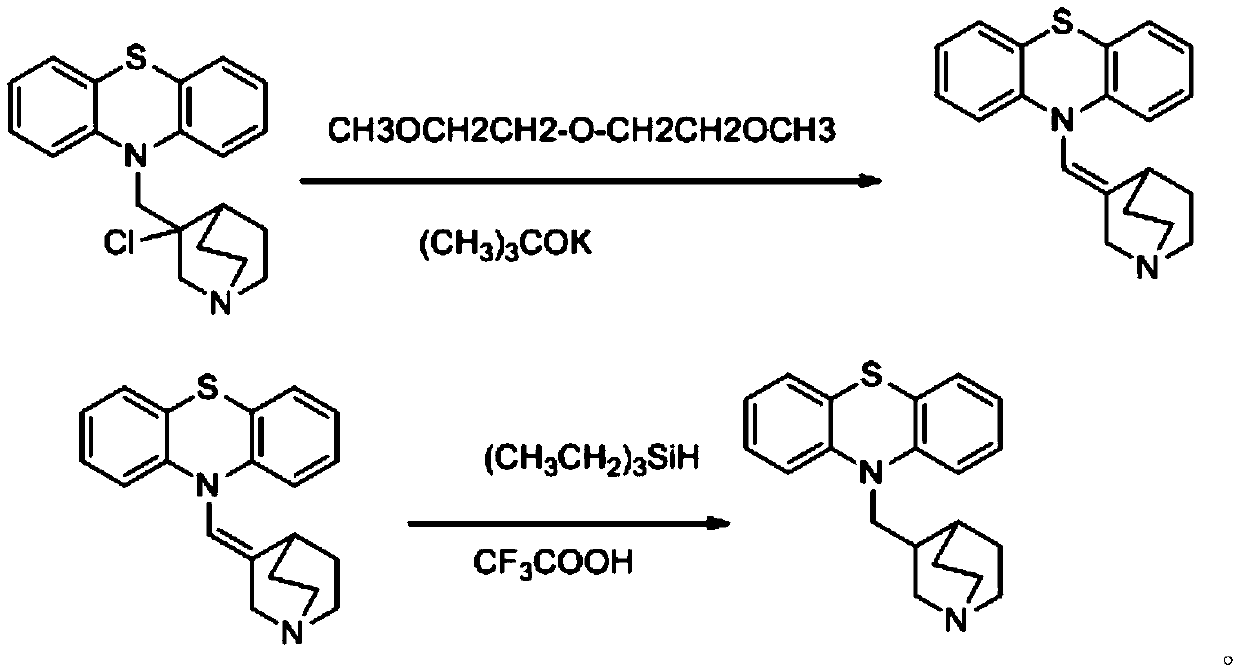

A technology of mequitazine and phenothiazine, which is applied in the field of mequitazine preparation, can solve problems such as hydrogenation of hydrogen, achieve mild reaction conditions, be suitable for industrial production, and reduce costs and waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Fill the synthesis tank with nitrogen for 20-30 minutes, and at the same time, vacuum 126.8 kg of diethylene glycol dimethyl ether into a clean and dry storage tank for use. After filling with nitrogen, open the feeding port of the synthesis tank, put in 45 kg of Cl-phenothiazine and 18.5 kg of potassium tert-butoxide, and cover the feeding port. Quickly add 126.8 kg of diethylene glycol dimethyl ether from the storage tank. After adding, start stirring to make the material heat up naturally. Without heating, the material can naturally heat up to 55-65°C. When the temperature reaches 55-65°C. Keep at 55-65°C for 2 hours. After the heat preservation is completed, heat to 70° C., and after heat preservation for 1 hour, take a sample for detection (HPLC), and determine the reaction end point (MQT2≤0.2%). After the reaction is complete, add 135 kg of drinking water, heat up, and when the inner temperature reaches 90-92° C., reflux and keep warm for 30 minutes. After...

Embodiment 2

[0041] (1) Fill the 5L reaction bottle with nitrogen for 20 minutes, and at the same time, pump 1400 g of diethylene glycol dimethyl ether into a clean and dry addition funnel for use. After filling with nitrogen, put in 500g of Cl-phenothiazine and 205kg of potassium tert-butoxide, and cover the feeding port. Quickly add 1400 g of diethylene glycol dimethyl ether from the storage tank. After the addition, start the stirring, let the material exotherm and heat up naturally, and keep it at 55-65°C for 2 hours. After the heat preservation is completed, heat to 70° C., and after heat preservation for 1 hour, take a sample for detection (HPLC), and determine the reaction end point (MQT2≤0.2%). After the reaction is complete, add 1500 g of drinking water, heat up, and when the internal temperature reaches 90° C., reflux and keep warm for 30 minutes. After the heat preservation is completed, start to cool down, and when the temperature drops to 20° C., add 700 g of drinking water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com