Differential elastic modulus support column array and vacuum glass

An elastic modulus, vacuum glass technology, applied in the manufacture of flat vacuum glass, differential elastic modulus support column arrays and vacuum glass fields, can solve problems such as bursting, support column vacancies, loss of vacuum insulation, etc., to achieve the greatest reduction Stress and maximum deformation, reducing support column vacancies, reducing the effect of glass damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

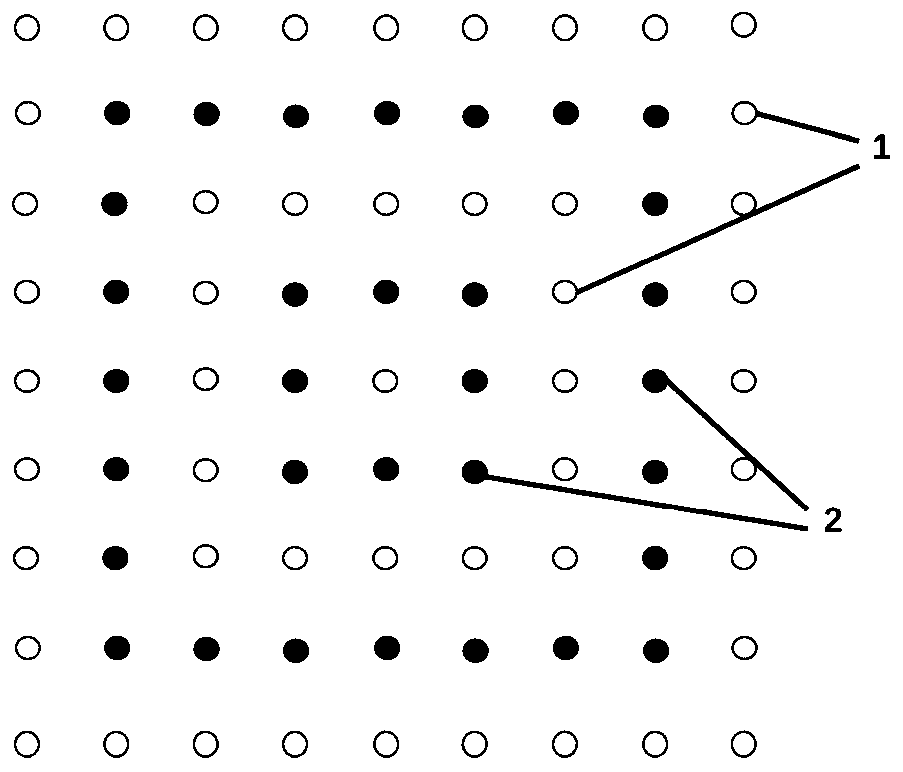

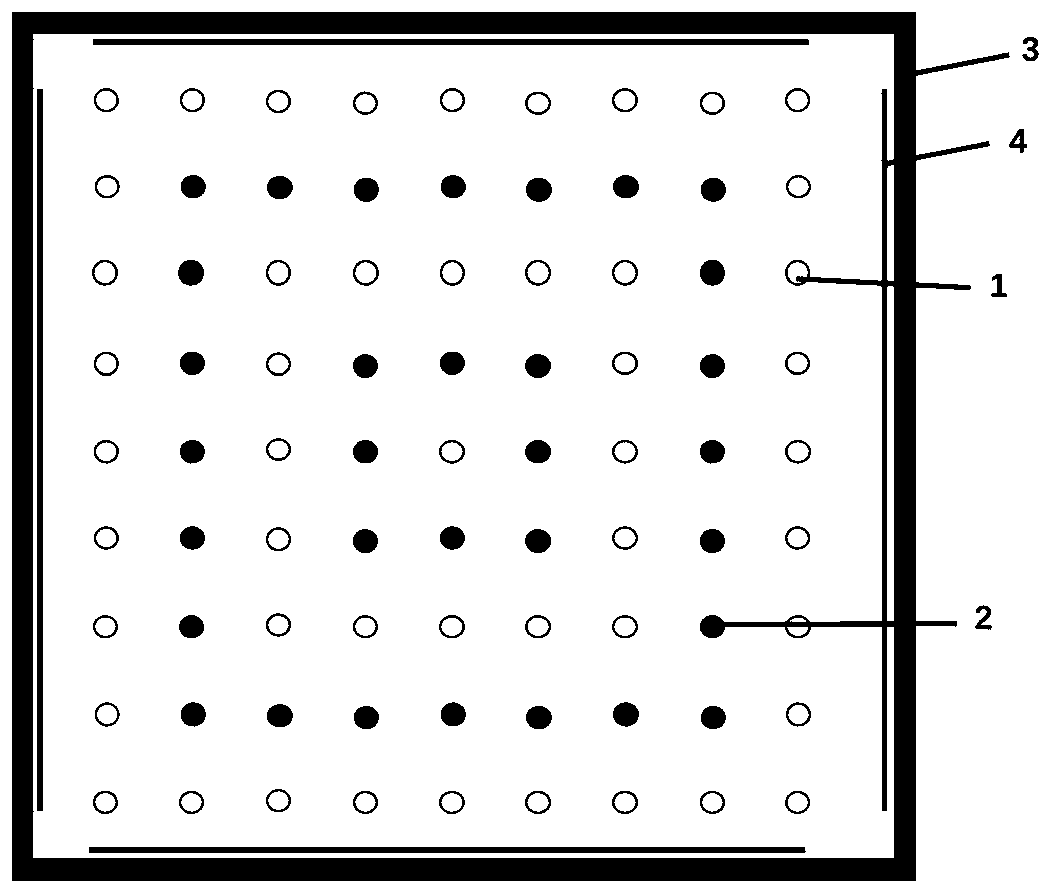

[0053] The invention provides a vacuum glass differential elastic modulus support column array, the material of the low elastic modulus support column is YH75 aluminum alloy, and its elastic modulus is 75GPa, and the material of the high elastic modulus support column is 301 stainless steel material. Its modulus of elasticity is 210 GPa. The ratio of the low elastic modulus to the high elastic modulus of the support column material is 0.34, and the spacing between the support column arrays is 30mm. The aluminum alloy and stainless steel support columns have the same height and are the same as the edge banding material, which is 0.2mm. The support column of the first circle near the sealing edge is made of aluminum alloy, the support column of the second circle close to the sealing edge is made of stainless steel, and so on. Circle the stainless steel support columns alternately until all the support columns are arranged.

[0054] Using a single stainless steel support column...

Embodiment 2

[0058] The invention provides a vacuum glass differential elastic modulus support column array, the material of the low elastic modulus support column is C97 copper alloy, and the elastic modulus is 95GPa; the material of the high elastic modulus support column is 301 stainless steel, and the elastic modulus The volume is 210GPa, and the spacing between the support column arrays is 40mm. The support column of the first circle near the sealing edge is made of copper alloy, the support column of the second circle close to the sealing edge is made of stainless steel, and so on, in the direction away from the sealing edge, one copper alloy support column, one The surrounding stainless steel support columns are carried out alternately until all the support columns are arranged. The ratio of the low elastic modulus to the high elastic modulus of the support column material is 0.45, and the height of the copper alloy support column and the stainless steel support column is the same, ...

Embodiment 3

[0063] The invention provides a vacuum glass differential elastic modulus support column array, the material of the low elastic modulus support column is QMn1.5 (Cu-1.5Mn) manganese bronze alloy, its elastic modulus is 105GPa, and the high elastic modulus The material of the supporting columns is 301 stainless steel, its modulus of elasticity is 210GPa, and the spacing between the supporting columns is 50mm. The support column of the first circle near the sealing edge is made of manganese bronze alloy, the support column of the second circle close to the sealing edge is made of stainless steel, and so on, in the direction away from the sealing edge, a surrounding glass support column, a The surrounding stainless steel support columns are carried out alternately until all the support columns are arranged. The ratio of the low elastic modulus to the high elastic modulus of the support column material is 0.5, and the height of the aluminum alloy support column and the stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com