Double braided layer high-pressure wear-resistant flexible pipe

A high-pressure wear-resistant and braided layer technology, applied in the direction of hoses, coatings, pipes, etc., can solve the problems of cumbersome production process of pipe body, easy to be corroded and wear-resistant, and low environmental protection standards, and achieve low environmental protection standards and difficult Splitting, increasing toughness and stress resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

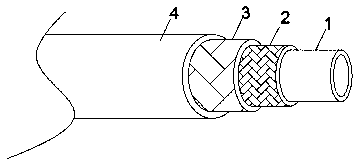

[0015] As shown in the figure, a double-braided high-pressure wear-resistant hose according to the present invention includes a hose body, and the hose body is sequentially provided with an inner tube 1, a first braided layer 2, a second braided layer 3 and wear-resistant layer 4, the inner tube 1 is extruded by a single-screw extruder, the first braided layer 2 is braided on the outer surface of the inner tube 1 by a braiding machine, and the second braided layer 3 The outer surface of the first braided layer 2 is braided by a braiding machine, and the wear-resistant layer 4 is extruded and coated on the outer surface of the second braided layer 3 by a single-screw extruder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com