Large-size rectangular jacking pipe jacking force estimation method based on displacement control

A rectangular pipe jacking and displacement control technology, applied in calculation, computer-aided design, special data processing applications, etc., can solve the problems of pipe structural damage, uncertainty, jacking failure, etc., and achieve the effect of high estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

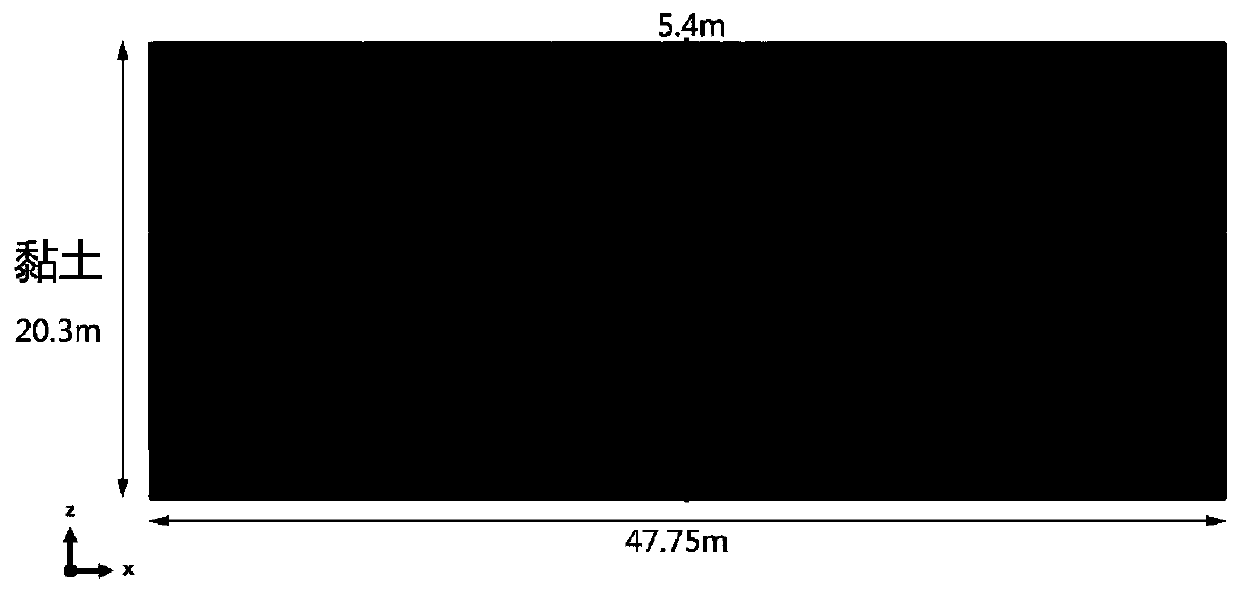

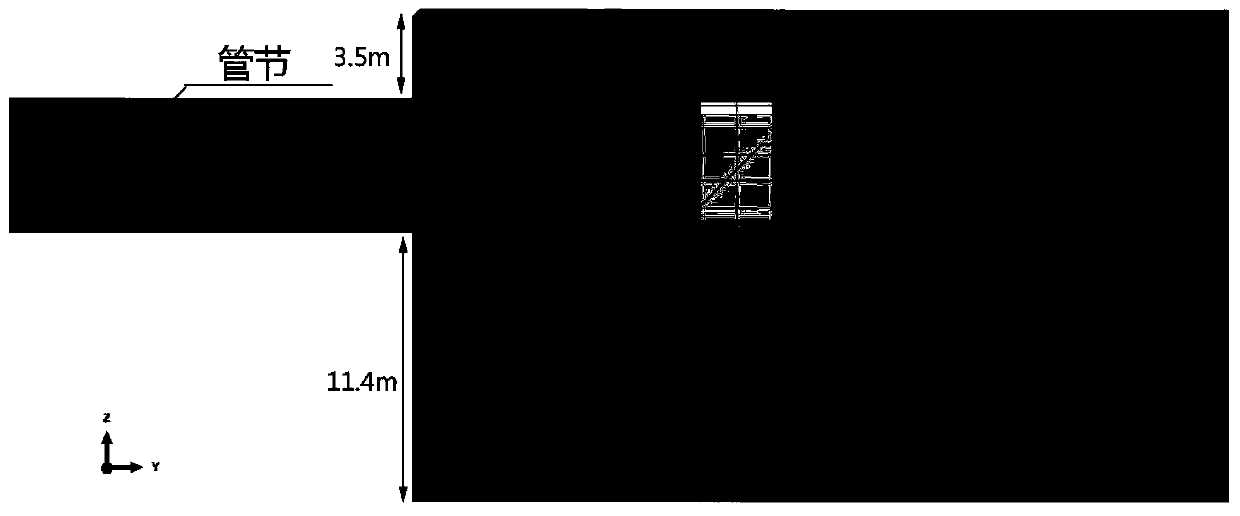

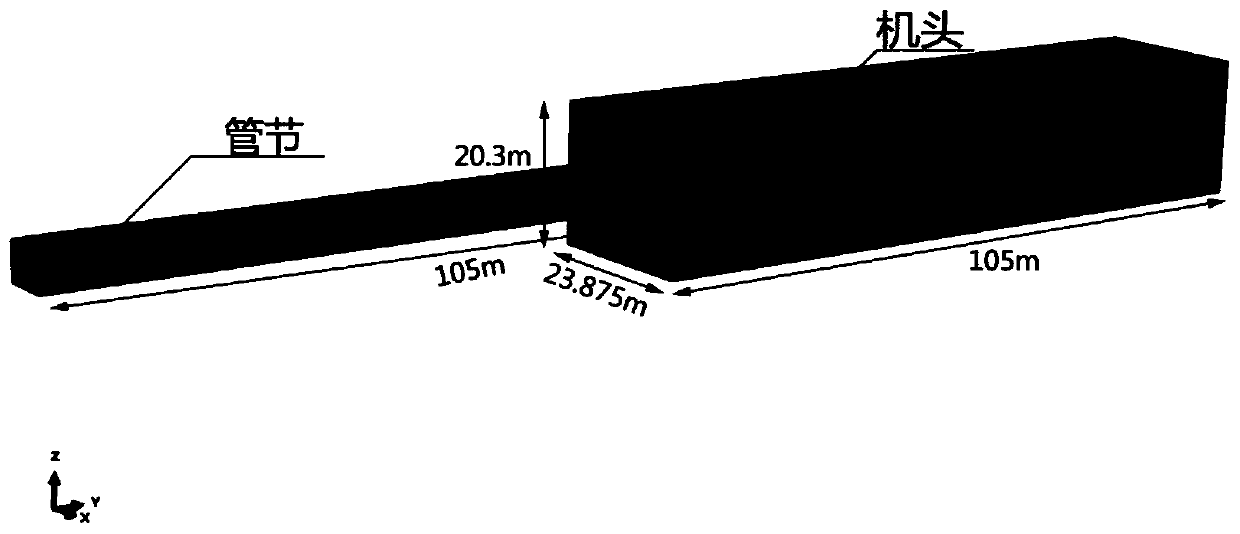

Method used

Image

Examples

Embodiment example A2

[0058] Pipe jacking implementation case A 2 (design parameters, construction conditions and A 1 Consistent): actual measurement, empirical formula, pipe jacking implementation case A 1 The comparison of the fitting relationship between the jacking force and the jacking distance obtained by the displacement control finite element method under the optimal grouting pressure scheme (grouting pressure scheme 4), this figure can be used as an indication of whether the displacement control finite element method is universal a verification.

[0059] Table 5. B under different grouting pressure schemes 1 Comparison of Projected Push Force Estimation Deviations

[0060]

[0061] Pipe jacking implementation case B 1 : Comparison of the fitting relationship between jacking force and jacking distance obtained from actual measurement, empirical formula, and displacement control finite element model under different grouting pressure schemes.

[0062] Table 6. Case B 2 Bias in jack-t...

Embodiment example B2

[0065] Pipe jacking implementation case B 2 (design parameters, construction conditions and B 1 Consistent): actual measurement, empirical formula, and pipe jacking implementation case B1 under the optimal grouting pressure scheme (grouting pressure scheme 1) The comparison of the fitting relationship between the jacking force and the jacking distance obtained by the displacement control unit method, the figure It can be used as a verification of whether the displacement control finite element method is universal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com