Antibacterial gel and preparation method thereof

A technology of gel and xanthan gum, applied in the field of medicine, can solve the problem of easy recurrence of drug resistance, and achieve the effects of good curative effect, good medication compliance, and promotion of bacteriostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of antibacterial gel,

[0047] Including phase A, phase B, phase C and phase D, said phase A, phase B, phase C and phase D are:

[0048] Phase A:

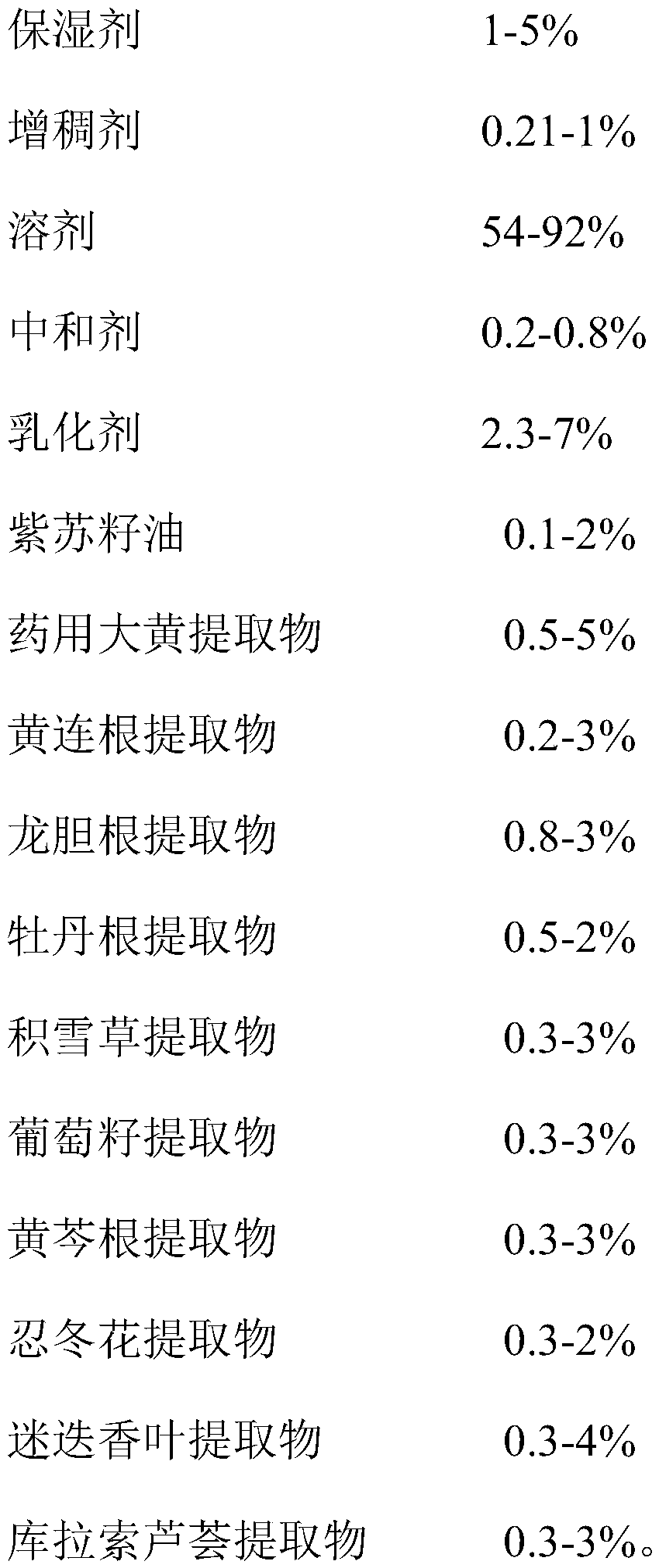

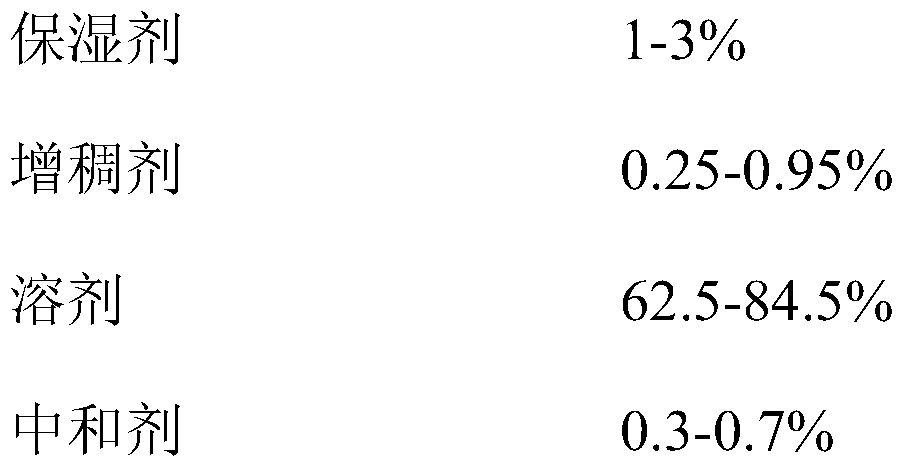

[0049] Humectant 1-5%

[0050] Thickener 0.2-1%

[0051] Solvent 51-91%

[0052] Phase B:

[0053] Neutralizer 0.2-0.8%

[0054] Solvent 1-3%

[0055] Phase C:

[0056] Emulsifier 2.3-7%

[0057] Perilla seed oil 0.1-2%

[0058] Phase D:

[0059]

[0060]

[0061] Prepared by a method comprising the following steps:

[0062] (1) Mix the components of phase B to obtain pre-dispersed phase B; mix the components of phase C to obtain pre-dispersed phase C.

[0063] (2) Mix the water and glycerin of the components of phase A, and add acrylates / C10-30 alkanol acrylate crosslinked polymer and xanthan gum under homogeneous conditions to obtain phase A;

[0064] (3) Add pre-dispersed phase B to phase A, heat up to 80-90°C while stirring, and then homogenize; ...

Embodiment 1

[0073]

[0074] Preparation:

[0075] (1) Mix the components of phase B to obtain a pre-dispersed phase B; mix the components of phase C to obtain a pre-dispersed phase C.

[0076] (2) Add the deionized water and glycerin of phase A into the emulsification pot and mix, and under the condition of low-speed homogeneity (30 rpm), cross-link and polymerize the acrylates / C10-30 alkanol acrylate in phase A Carbopol Ultrez 21 Polymer) and xanthan gum were slowly sprinkled into the emulsification pot and homogenized for 3 minutes to obtain phase A.

[0077] (3) Add pre-dispersed phase B into phase A, heat up to 82-85°C while stirring, and homogenize at medium speed (60 rpm) for 4 minutes.

[0078] (4) Until it is fully dispersed, cool down to 60-65°C, add the pre-dispersed C phase components, stir well, and homogenize (2800 rpm) for 2 minutes;

[0079] (5) After homogenization, cool down to below 40°C, add phase D substances in turn, stir well, take samples, test, filter, and disch...

Embodiment 2

[0081]

[0082]

[0083] Preparation:

[0084] (1) Mix the components of phase B to obtain a pre-dispersed phase B; mix the components of phase C to obtain a pre-dispersed phase C.

[0085] (2) Add the deionized water and glycerin of phase A into the emulsification pot and mix them, and crosslink and polymerize the acrylates / C10-30 alkanol acrylate in phase A under the condition of low-speed homogeneity (25 rpm) (Carbopol Ultrez 21 Polymer) and xanthan gum were slowly sprinkled into the emulsification pot, and homogenized for 2 minutes to obtain phase A.

[0086] (3) Add pre-dispersed phase B into phase A, heat up to 82-85°C while stirring, and homogenize at a medium speed (60 rpm) for 5 minutes.

[0087] (4) Until it is fully dispersed, cool down to 60-65°C, add the pre-dispersed C phase components, stir well, and homogenize (2800 rpm) for 3 minutes;

[0088] (5) Cool down to below 40°C, add phase D substances in turn, stir well, take samples, test, filter, discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com