Electrode material and preparation method thereof, and aluminum electrolytic capacitor

A technology of electrode material and electrode foil, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of mild operating conditions, superior electrical performance, and easy automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

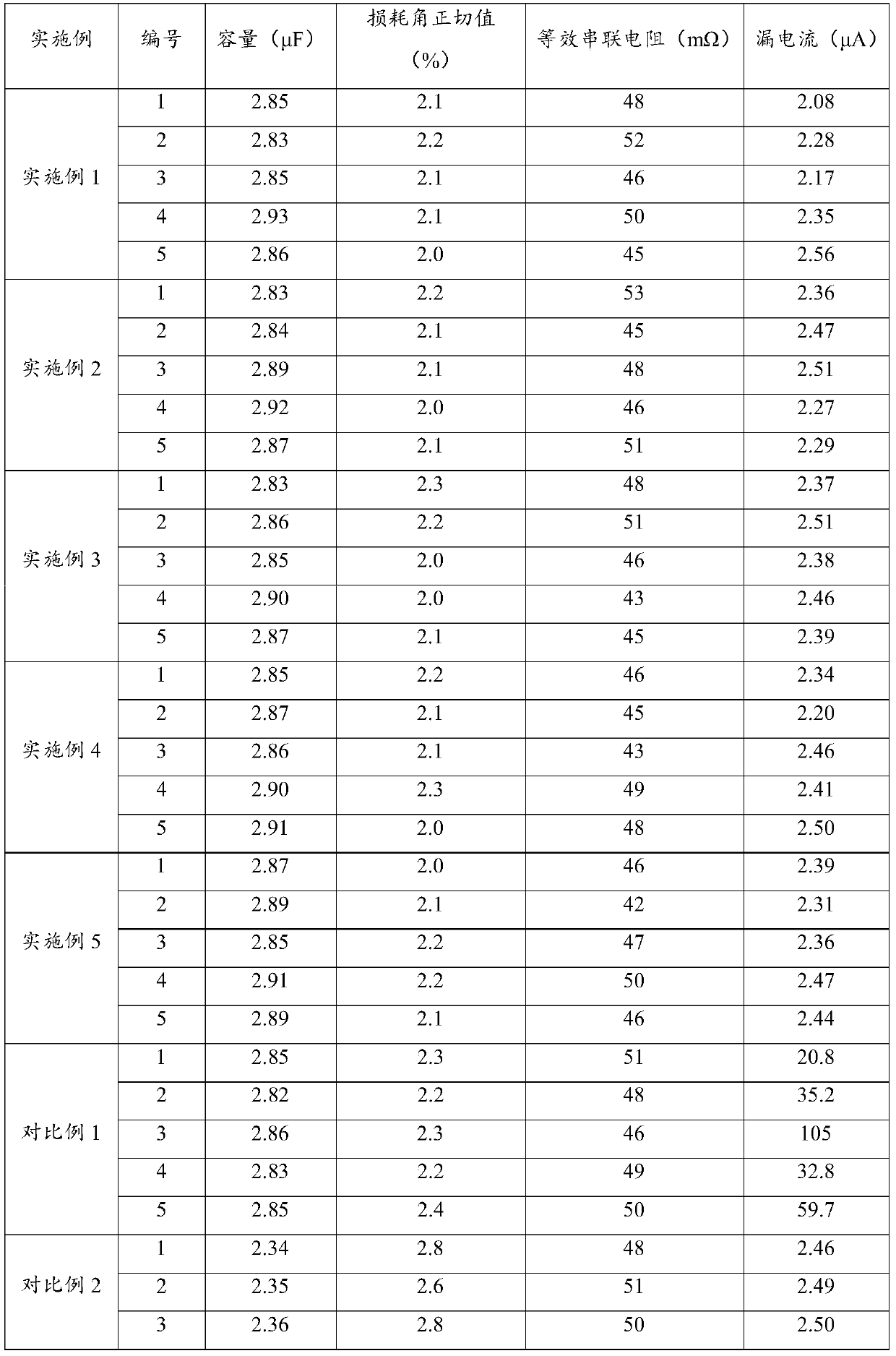

Examples

Embodiment 1

[0062] A conductive polymer electrode material

[0063] (1) Pretreatment: Mix 1000g of deionized water and 500g of absolute ethanol evenly, then add 63g of silane coupling agent 171 and stir magnetically for 10 minutes, then pour it into the dipping tank, put it into the aluminum foil to be pretreated, dip for 5 minutes, and air dry for 15 minutes , and then placed in an oven for 60 minutes at 120°C.

[0064] (2) Mix 2500g of absolute ethanol and 80g of 3-methoxythiophene evenly, then magnetically stir for 10min to prepare a monomer solution, then pour it into the dipping tank, put it into the pretreated aluminum foil, dip for 3min, then put Into a constant temperature and humidity chamber with a temperature of 30° C. and a humidity of 60% RH for 10 minutes.

[0065] (3) Mix 2500g of deionized water, 1000g of sodium persulfate and 5g of sodium alkylbenzene sulfonate evenly, then stir for 60 minutes to prepare an oxidizing agent solution, then pour it into the dipping tank, an...

Embodiment 2

[0074] (1) Pretreatment: Mix 1000g of deionized water and 500g of absolute ethanol evenly, then add 55g of silane coupling agent 171 and magnetically stir for 10min, then pour it into the dipping tank, put it into the aluminum foil to be pretreated, dip for 5min, and air dry for 15min , and then placed in an oven for 60 minutes at 120°C.

[0075] (2) Mix 2500g of absolute ethanol and 90g of N-ethylpyrrole evenly, then stir magnetically for 10 minutes, prepare a monomer solution, then pour it into the dipping tank, put it into the pretreated aluminum foil, dip it for 4 minutes, and then put it in 10 minutes in a constant temperature and humidity chamber with a temperature of 40° C. and a humidity of 50% RH.

[0076] (3) Mix 2500g of deionized water, 1000g of ferric p-toluenesulfonate and 5g of sodium alkylbenzenesulfonate evenly, then stir for 60min to make an oxidant solution, then pour it into the dipping tank, and put it into the impregnated monomer solution The aluminum fo...

Embodiment 3

[0085] A conductive polymer electrode material

[0086] (1) Pretreatment: Mix 1000g of deionized water and 500g of absolute ethanol evenly, then add 15g of silane coupling agent 172 and stir magnetically for 10min, then pour it into the dipping tank, put it into the aluminum foil to be pretreated, dip for 5min, and air dry for 15min , and then placed in an oven for 60 minutes at 120°C.

[0087] (2) Mix 2500g of absolute ethanol and 1250g of 3-methoxythiophene evenly, then magnetically stir for 10min to prepare a monomer solution, then pour it into the dipping tank, put it into the pretreated aluminum foil, dip for 3min, then put Into a constant temperature and humidity chamber with a temperature of 30° C. and a humidity of 60% RH for 10 minutes.

[0088] (3) Mix 2500g of deionized water, 250g of sodium persulfate and 12.5g of sodium alkylbenzene sulfonate evenly, then stir for 60 minutes to prepare an oxidizing agent solution, then pour it into the dipping tank, and put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com