Ablation-resistant bimetal combined piston ring, internal combustion engine and sealing method

A piston ring and bimetal technology, applied in the design and manufacture of internal combustion engine parts, can solve the problems of not seriously considering the sealing of the contact surface of the two rings, increasing the wear rate of the piston and cylinder liner, and reducing the service life of the piston ring, etc., to achieve improvement Heat deformation problem, improve lubrication effect, reduce the effect of carbon deposition problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

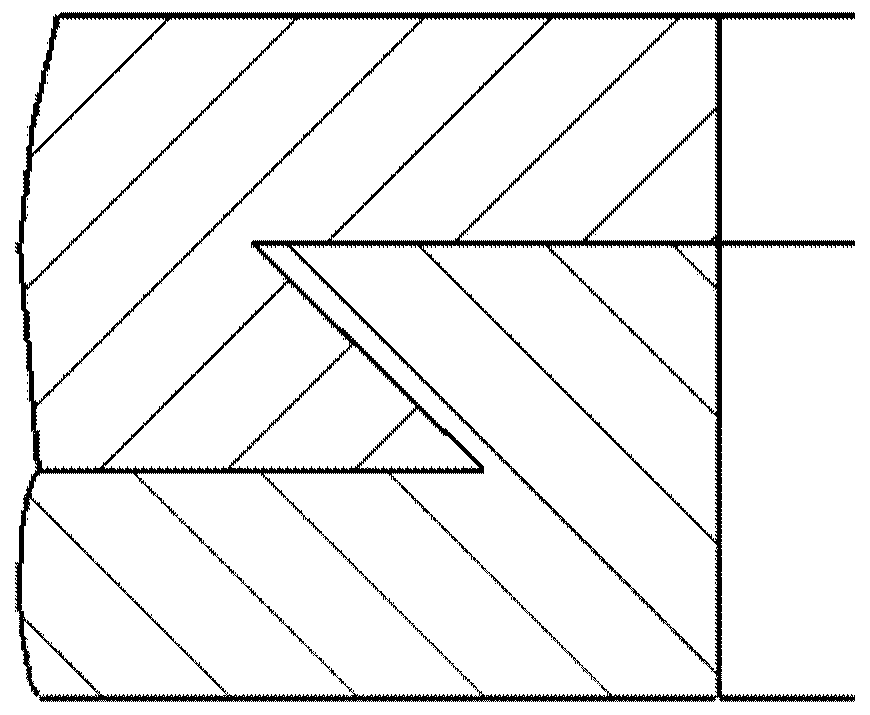

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0042] Since the position of the product of the present invention can be changed at will, the location words such as "up", "down", "left" and "right" in the present invention only represent relative positional relationships, and are not used to limit absolute positions. location relationship.

[0043] The invention discloses an ablation-resistant bimetal combined piston ring, an internal combustion engine and a sealing method, which mainly solve the problem of mechanical deformation of the piston ring and the indirect air leakage problem, specifically including deformation of the ring due to uneven heating of the upper and lower ring surfaces ; The inherent air leakage problem of the piston ring of the internal combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com