Elasticity enhancement cotton-like fiber and preparation method thereof

A technology of imitating cotton fibers and a manufacturing method is applied in the field of texturing fibers, and can solve the problems of adding texturized yarns and insufficiency of product functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

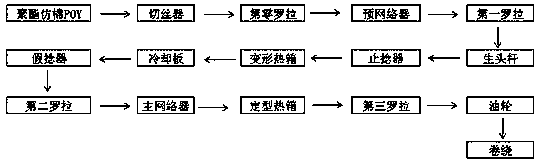

Image

Examples

Embodiment Construction

[0012] The present invention will further illustrate the present invention with the following examples of producing 50S textured cotton-like fibers, but the protection scope of the present invention is not limited to the examples.

[0013] Polyester cotton-like POY is made of isophthalic acid, ethylene glycol antimony, cobalt acetate, stabilizer Irganox 1010, triphenyl phosphite, titanium dioxide and purified terephthalic acid, ethylene glycol through chemical reaction to generate cotton-like polyester melt , And then directly spun, wherein: the addition amount of isophthalic acid is 1.5%-5% of the total mass of the obtained cotton-like polyester, and the added amount of ethylene glycol antimony is 0.02 of the total mass of the obtained cotton-like polyester %—0.03%, the amount of cobalt acetate added is 0.004%—0.006% of the total mass of the obtained cotton-like polyester, the stabilizer Irganox1010 added is 0.03%—0.05% of the total mass of the obtained cotton-like polyester, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com