Elasticity-improved hydrophilic cotton-like fiber and manufacturing method thereof

A cotton-like fiber and hydrophilic technology, applied in the field of stretched fibers, can solve the problems of adding stretched yarns and incomplete product functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

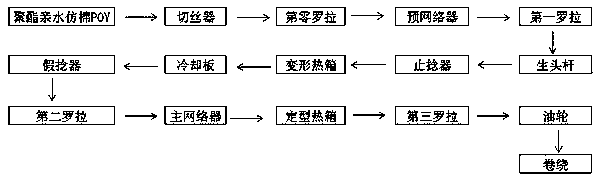

[0012] combine figure 1 , the present invention will further illustrate the present invention with the following examples of producing 40S stretched hydrophilic cotton-like fibers, but the protection scope of the present invention is not limited to the examples.

[0013] Polyester hydrophilic cotton-like POY is made of polypropylene glycol, ethylene glycol antimony, cobalt acetate, stabilizer Irganox1010, triphenyl phosphite, titanium dioxide, purified terephthalic acid, and ethylene glycol to form a cotton-like polyester melt. body, and then formed by direct spinning, wherein: the addition of polypropylene glycol is 2.5%-5% of the total mass of the obtained hydrophilic cotton-like polyester, and the added amount of ethylene glycol antimony is the total mass of the obtained hydrophilic cotton-like polyester. 0.02%-0.03% of the mass, the amount of cobalt acetate added is 0.004%-0.006% of the total mass of the obtained hydrophilic cotton-like polyester, and the amount of stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com