A self-made low-defect ultra-high-strength lightweight aggregate and its preparation method and application

A low-defect, aggregate technology, applied in the field of building materials, can solve the problems of poor coordination between aggregate and matrix, and achieve the effect of outstanding weight reduction, smooth and dense surface, and less internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

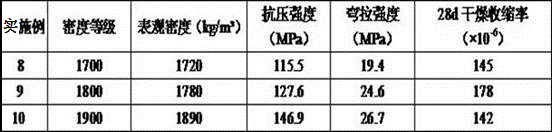

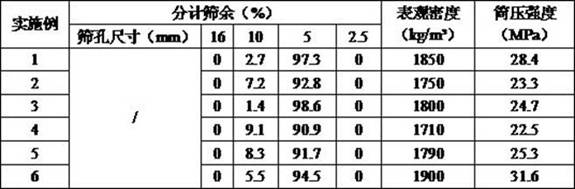

Examples

Embodiment 1

[0027]A self-made low-defect ultra-high-strength lightweight aggregate, including dry material, admixture and water. The dry material is made of the following raw materials in parts by weight: 700 parts of cement, 90 parts of fly ash, 210 parts of silica fume, hollow glass micro 90 parts of beads, 4 parts of polyvinyl alcohol fiber, 360 parts of quartz sand; the admixture is made of the following raw materials in parts by weight: 1.8 parts of active activator, 28 parts of water reducer, 0.06 part of defoamer; parts by weight of water for 135 servings.

Embodiment 2

[0029] A self-made low-defect ultra-high-strength lightweight aggregate, including dry materials, additives and water. The dry materials are made of the following raw materials in parts by weight: 770 parts of cement, 110 parts of fly ash, 230 parts of silica fume, hollow glass micro 135 parts of beads, 8 parts of polyvinyl alcohol fiber, 520 parts of quartz sand; the admixture is made of the following raw materials in parts by weight: 2.2 parts of active activator, 35 parts of water reducer, 0.08 part of defoamer; parts by weight of water for 155 copies.

Embodiment 3

[0031] A self-made low-defect ultra-high-strength lightweight aggregate, including dry material, admixture and water. The dry material is made of the following raw materials in parts by weight: 735 parts of cement, 100 parts of fly ash, 220 parts of silica fume, hollow glass micro 112.5 parts of beads, 6 parts of polyvinyl alcohol fiber, 440 parts of quartz sand; the admixture is made of the following raw materials in parts by weight: 2 parts of active activator, 31.5 parts of water reducer, 0.07 part of defoamer; parts by weight of water for 145 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com