Fully-automatic ammonia-preparing ammonia-adding integrated machine device and fully-automatic ammonia-preparing ammonia-adding method

A fully automatic, all-in-one machine technology, applied in program control, electrical program control, neutralized water/sewage treatment, etc., can solve problems such as changes in the concentration of ammonia solution, corrosion of equipment, changes in ammonia addition, etc., and achieve simple devices and methods Practical, improve safety and economy, and maintain stable conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

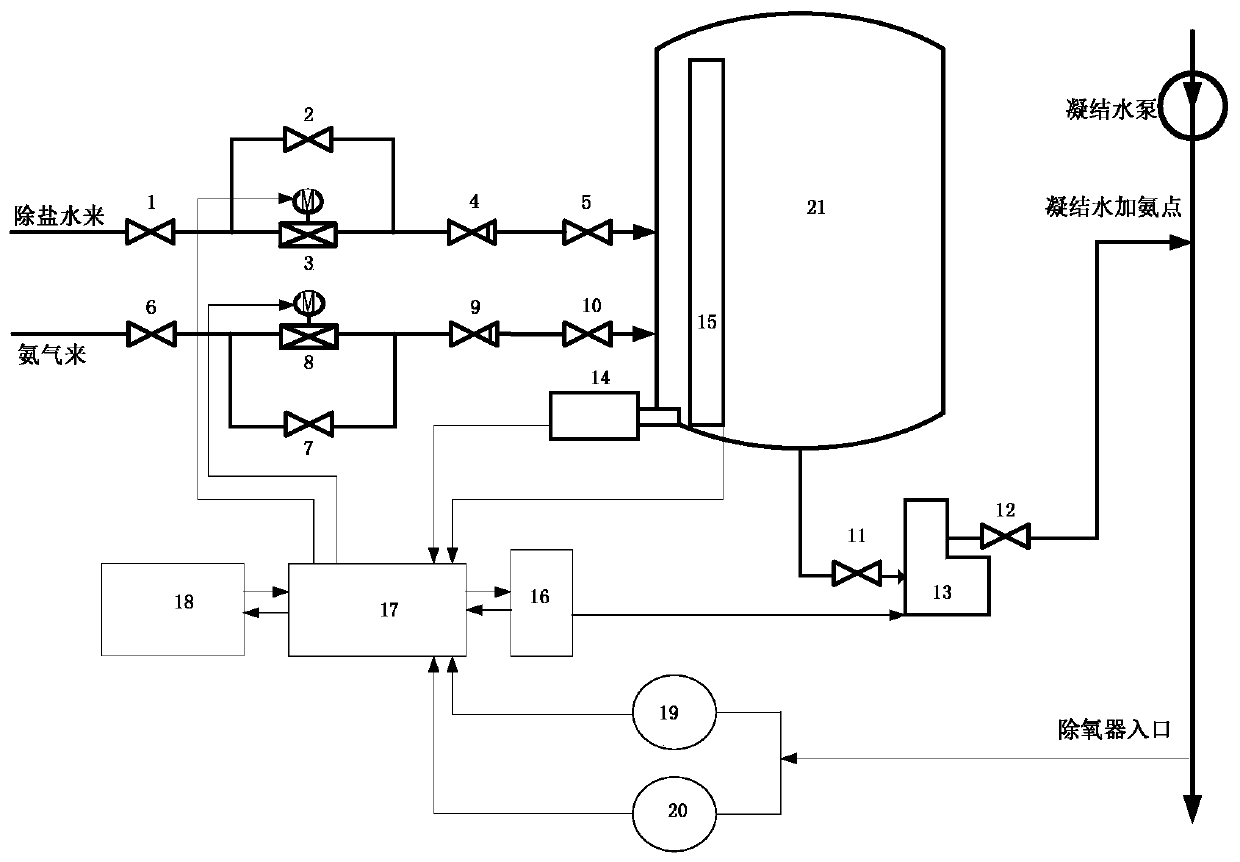

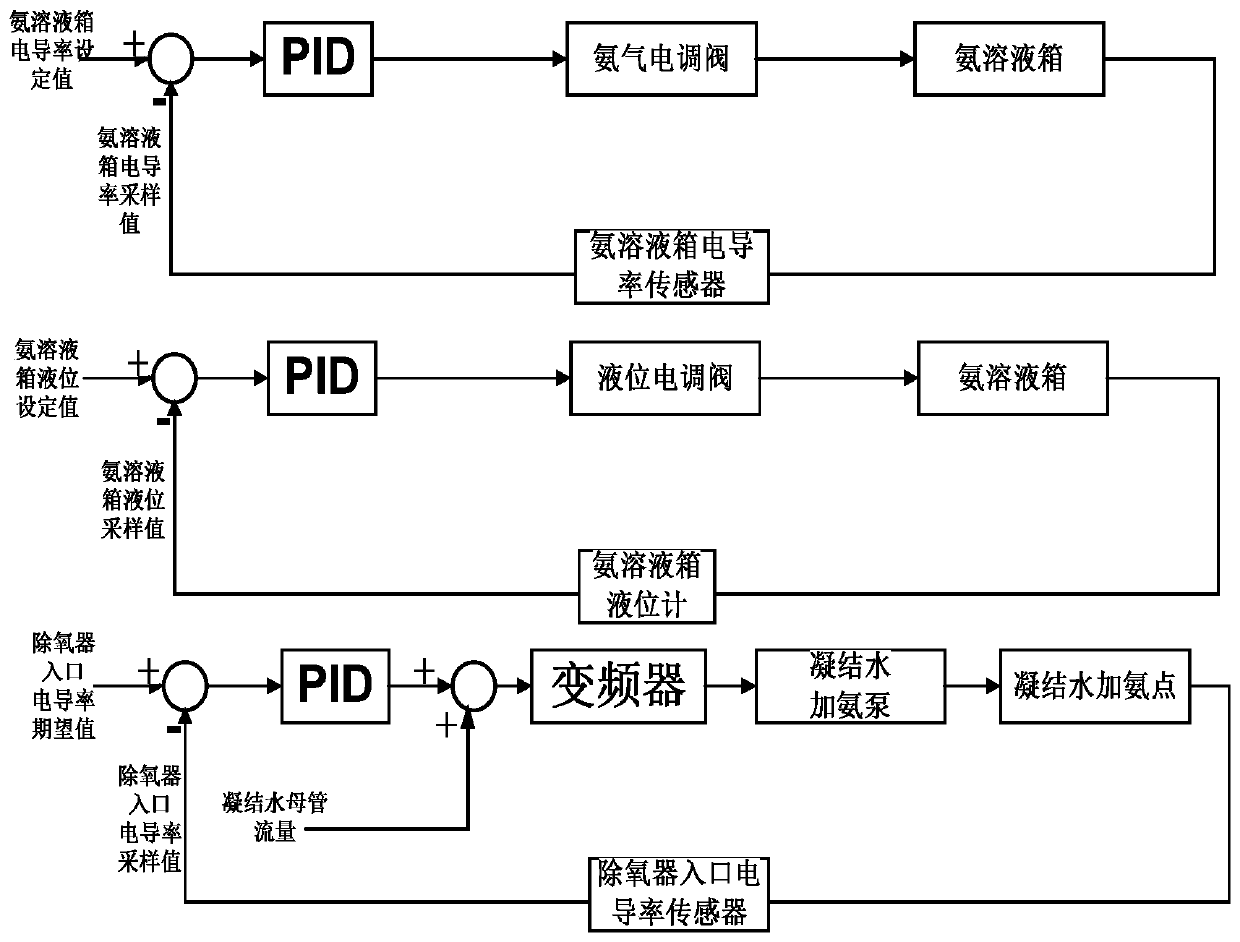

[0027] Attached below figure 1 And attached figure 2 The specific embodiment of the present invention will be further described.

[0028] as attached figure 1 As shown, the full-automatic ammonia distribution and ammonia addition integrated machine device of the present invention includes a desalinated water primary stop valve 1, a desalinated water electric regulating valve 3, and a desalinated water check valve 4 sequentially arranged on the desalinated water pipeline connected to the ammonia solution tank 21 And desalinated water secondary cut-off valve 5, the ammonia gas primary cut-off valve 6, the ammonia gas electric control valve 8, the ammonia gas check valve 9 and the ammonia gas secondary cut-off valve 10 that are arranged successively on the ammonia gas pipeline connected with the ammonia solution tank 21 The desalted water check valve 4 and the ammonia gas check valve 9 are in order to prevent the ammonia solution in the ammonia solution tank 21 from backfillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com