Upright diluted oil circulation ring mold pellet mill

A granulator, vertical technology, applied in the field of thin oil circulation vertical ring die granulator, can solve problems such as affecting output and compression efficiency, increasing manufacturing difficulty and cost, and breaking gear teeth in the reduction box, reducing the Equipment maintenance cost, simplify power system design, and eliminate the effect of secondary crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

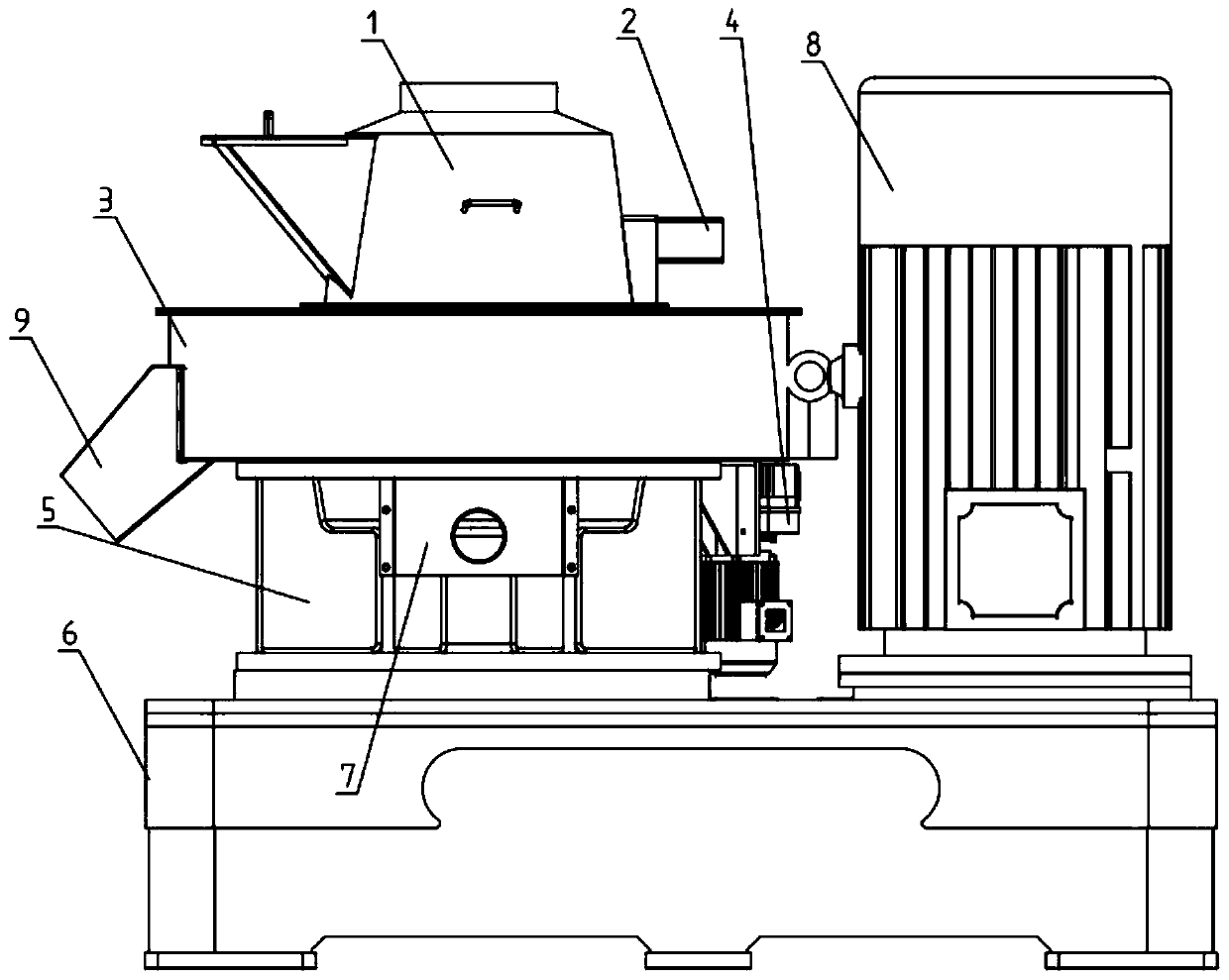

[0049] Such as Figure 1-7 As shown, this embodiment provides a thin oil circulation vertical ring die granulator, which includes a cast-molded granulation main body. The granulation main body is divided into upper, middle and lower parts. The uppermost part is the feeding shell and the pressing chamber. The middle part is the connecting section of the rotating main shaft, and the lower part is the power transmission mechanism of the rotating main shaft.

[0050] In this embodiment, the power transmission mechanism includes a reducer 6 installed at the lower part of the granulation main body, the power input shaft of the reducer 6 is connected to the motor 8, the power output shaft of the reducer 6 is connected to the rotating main shaft 22, and the rotating main shaft 22 is vertically installed on the granulation main body, the rotating main shaft 22 is located at the top of the reducer 6, and is fixed with the reducer casing through the connecting seat 5, and the middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com