A small biomass heating system

A heating system and biomass technology, applied in the field of small biomass heating systems, can solve the problems of scarcity of small biomass boilers, poor heating effect, heat waste of solar collectors, etc., to achieve high-efficiency heating effect and simple operation , Improve the effect of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described and illustrated through specific examples below.

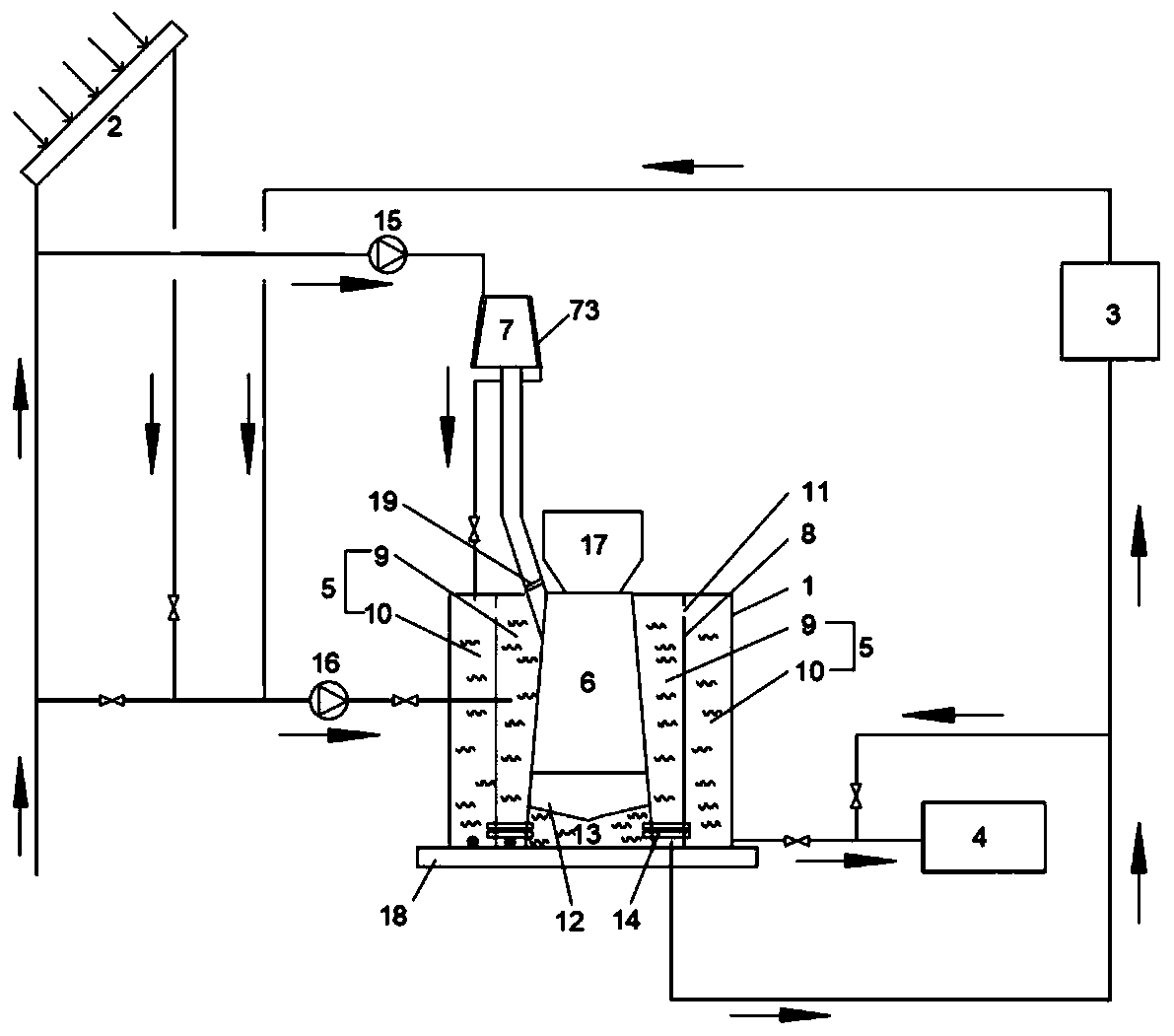

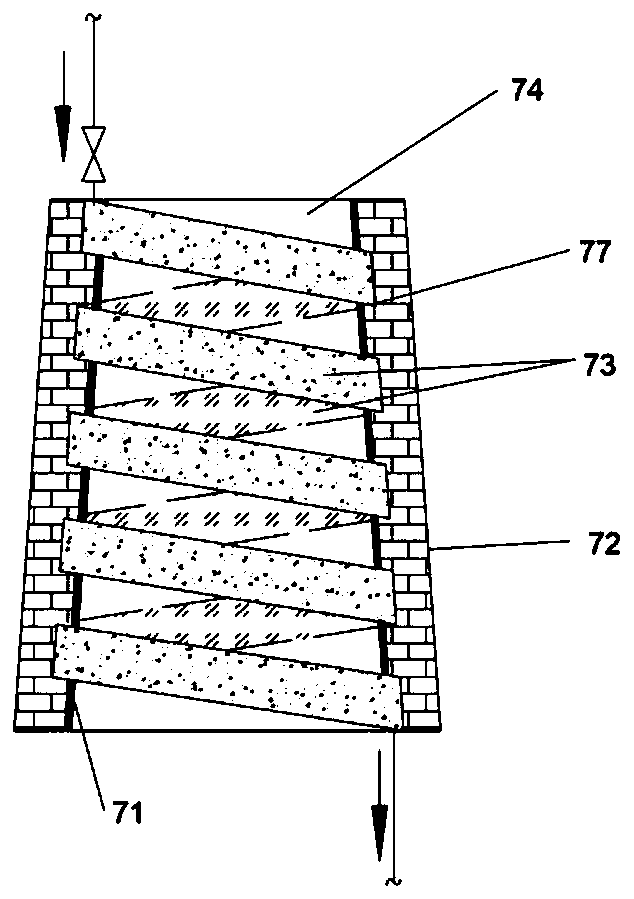

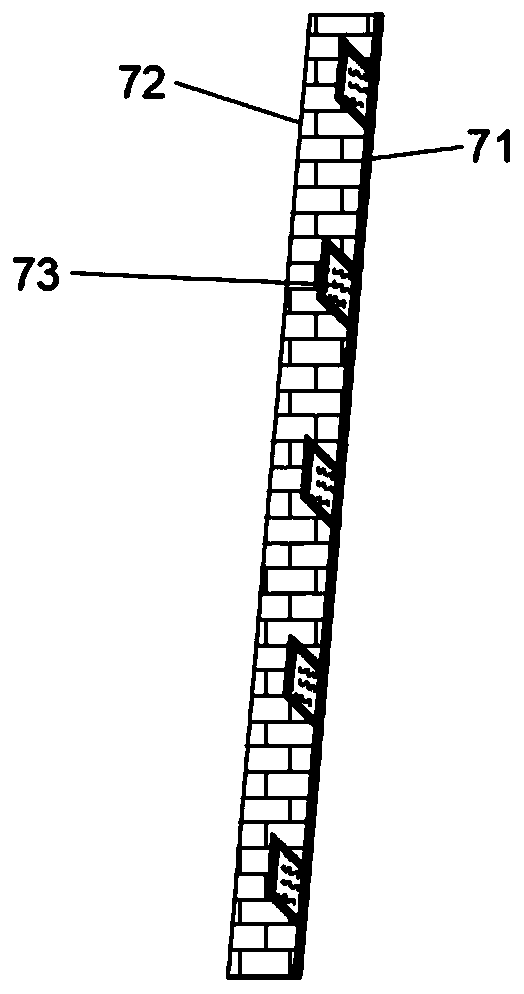

[0035] This embodiment provides a small biomass heating system, such as figure 1 As shown, it includes a stove 1, a solar heat collector 2, a radiator 3, and domestic water equipment 4, and the stove 1 includes a water tank 5, a furnace 6 and a chimney 7. A stove 17 is placed above the furnace 6, and the outer wall of the furnace 6 is provided with a fire outlet, and the furnace 6 communicates with the chimney 7 through the fire outlet. The outer wall of the furnace 6 is also provided with a discharge port and an air inlet. The discharge port is used to place fuel, and the interior of the furnace 6 communicates with the outside world through the discharge port. The induced draft fan supplements the air inside the furnace 6 through the air inlet, so that the fuel can be fully burned. A water tank 5 is provided on the outer wall of the furnace 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com