Anisotropic nano-cellulose aerogel and preparation method and device thereof

A nanocellulose, anisotropic technology, applied in the field of material science, can solve the problems of long transmission path, disordered microporous structure, and reduced application performance of materials, and achieve good mechanical compression resistance, good stability, and high porosity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

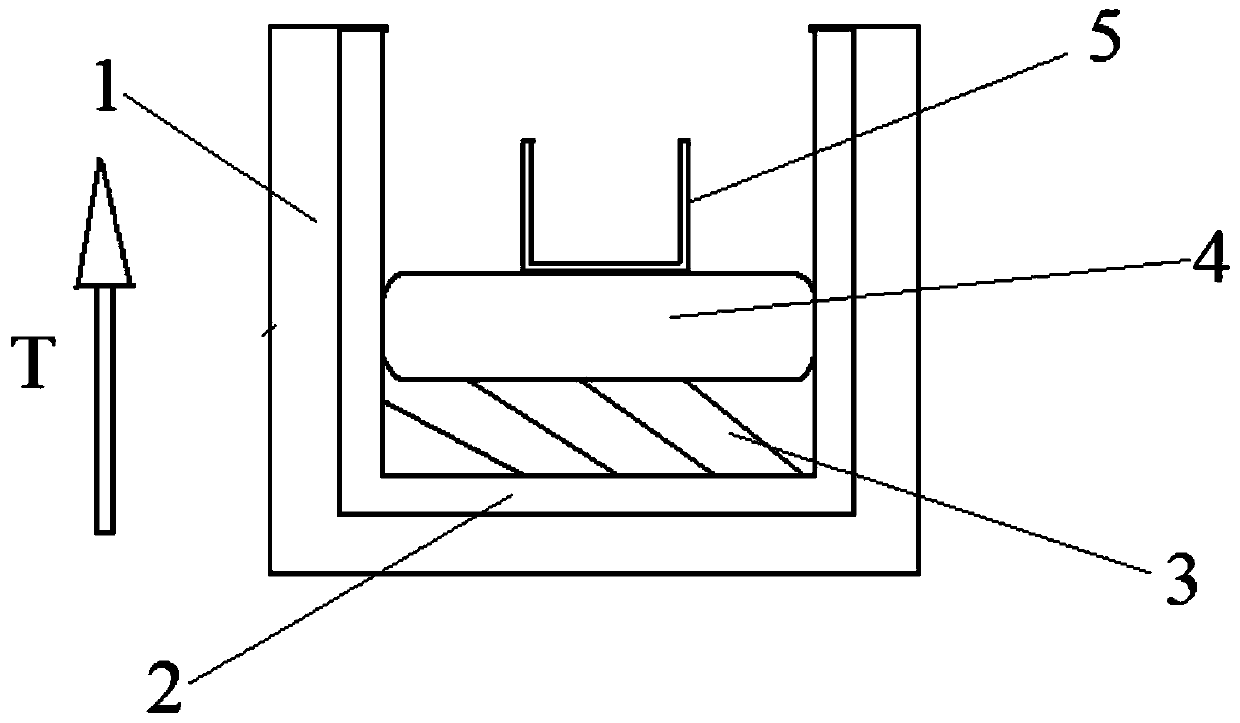

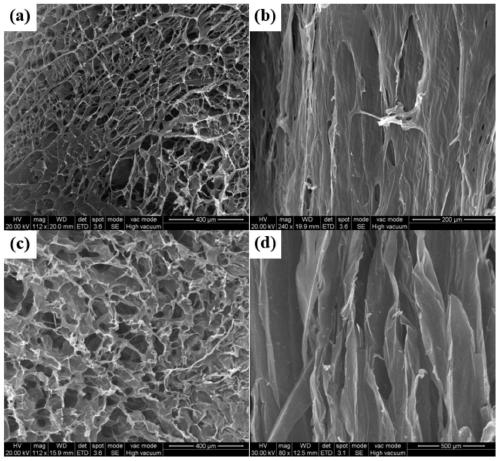

[0031] A preparation method of anisotropic nano-cellulose airgel, comprising the following steps:

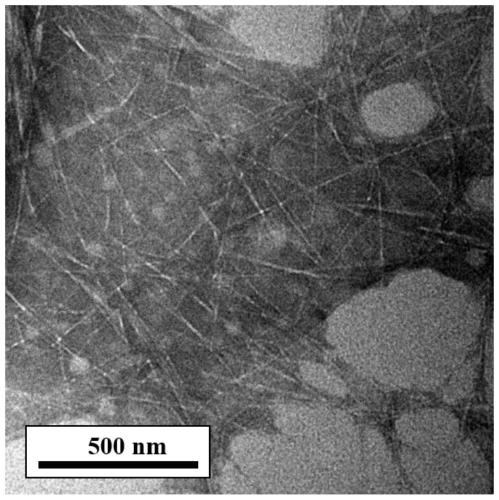

[0032] Step 1, ultrasonically dispersing the nanocellulose prepared by the TEMPO oxidation method into water to obtain a nanocellulose dispersion. Among them, the specific steps for the preparation of TEMPO oxidation method are: put deionized water (500mL) in a beaker, add 0.08g of TEMPO, 0.5g of NaBr, and 7g of wood pulp fibers in turn, and mix and stir for 20min on a heating type magnetic stirrer . Add a certain volume of 10% NaClO solution. Then adjust the pH of the system with 0.2 mol / L hydrochloric acid solution, and continue stirring at room temperature. During the reaction process, 0.3 mol / L sodium hydroxide solution was continuously added dropwise to maintain the system pH=11 until the sodium hydroxide was no longer consumed, and 5 mL of ethanol was added to terminate the reaction. The product was washed with deionized water several times to neutrality, an appropriate...

specific Embodiment 2

[0036] A preparation method of anisotropic nano-cellulose airgel, comprising the following steps:

[0037] Step 1, ultrasonically dispersing the nanocellulose prepared by the TEMPO oxidation method into water to obtain a nanocellulose dispersion. Among them, the specific steps for the preparation of TEMPO oxidation method are: put deionized water (400mL) in a beaker, add 0.08g of TEMPO, 0.5g of NaBr, and 5g of wood pulp fiber in turn, and mix and stir for 20min on a heating type magnetic stirrer . Add a certain volume of 10% NaClO solution. Then adjust the pH of the system with 0.4 mol / L hydrochloric acid solution, and continue stirring at room temperature. During the reaction process, 0.4 mol / L sodium hydroxide solution was continuously added dropwise to maintain the system pH=10 until the sodium hydroxide was no longer consumed, and 15 mL of ethanol was added to terminate the reaction. The product was washed with deionized water several times to neutrality, an appropriate...

specific Embodiment 3

[0041] A preparation method of anisotropic nano-cellulose airgel, comprising the following steps:

[0042] Step 1, ultrasonically dispersing the nanocellulose prepared by the TEMPO oxidation method into water to obtain a nanocellulose dispersion. Among them, the specific steps for the preparation of TEMPO oxidation method are: put deionized water (500mL) in a beaker, add 0.08g of TEMPO, 0.5g of NaBr, and 2g of wood pulp fiber in turn, and mix and stir for 20min on a heating type magnetic stirrer. . Add a certain volume of 10% NaClO solution. Then adjust the pH of the system with 0.2 mol / L hydrochloric acid solution, and continue stirring at room temperature. During the reaction process, 0.1 mol / L sodium hydroxide solution was continuously added dropwise to maintain the system pH=9 until the sodium hydroxide was no longer consumed, and 10 mL of ethanol was added to terminate the reaction. The product was washed with deionized water several times to neutrality, an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com