Laser and magnetorheological fluid coupling polishing device

A magnetorheological fluid and polishing device technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, optical surface grinder, etc., can solve the problem that the magnetorheological fluid cannot be recycled, the shape of the processed workpiece is limited, and the surface roughness Improve the polishing efficiency and quality, ingenious mechanical design, and controllable polishing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

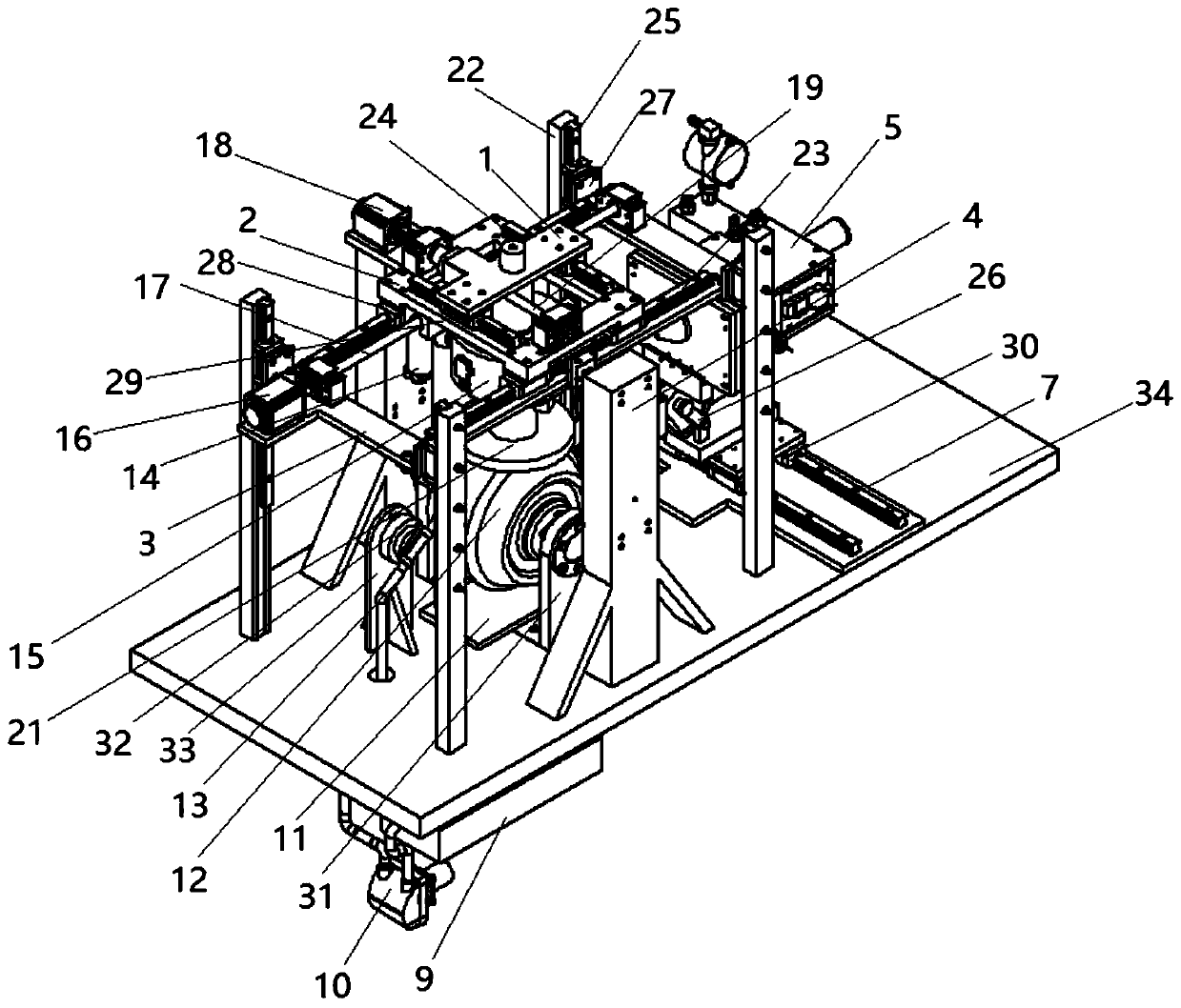

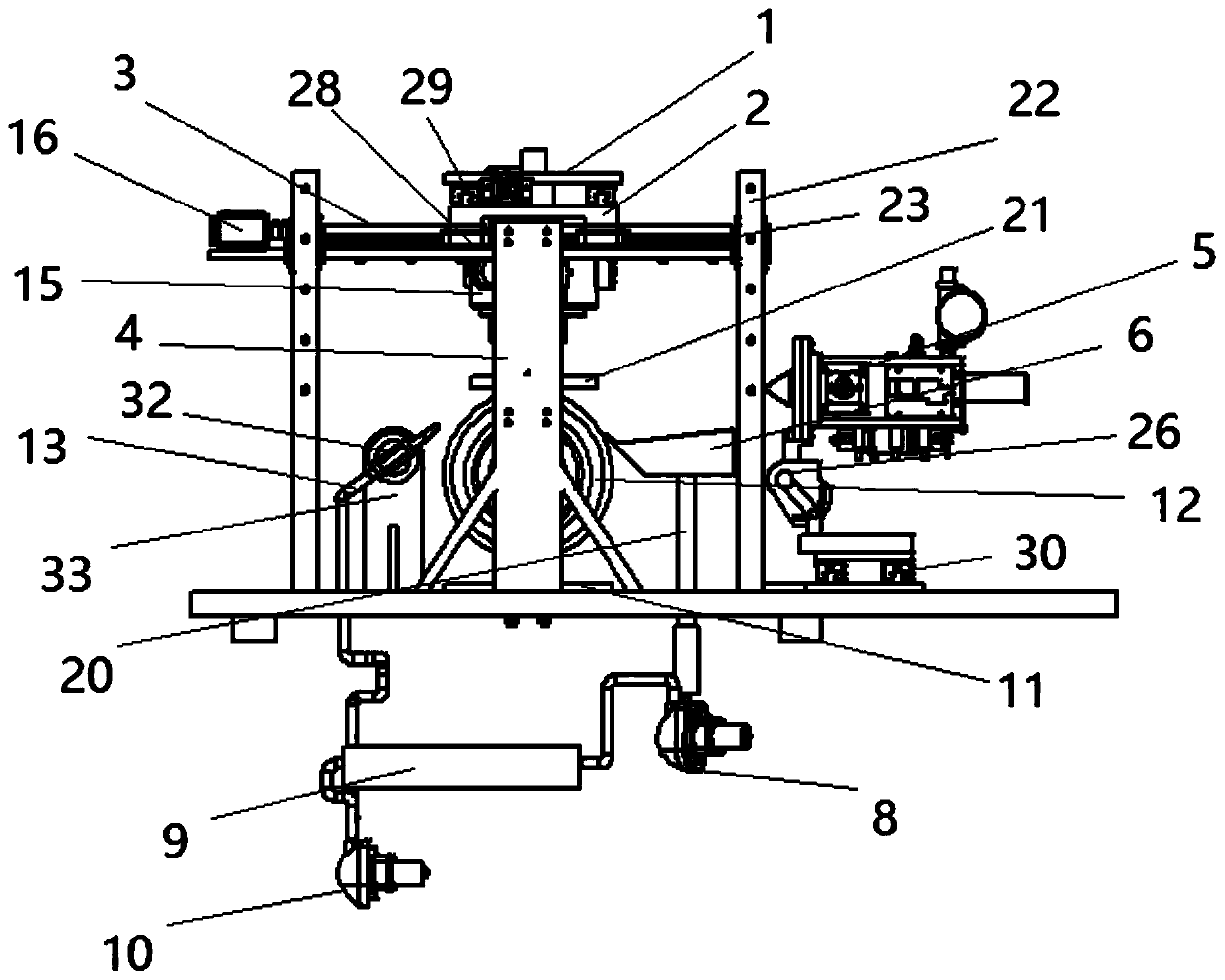

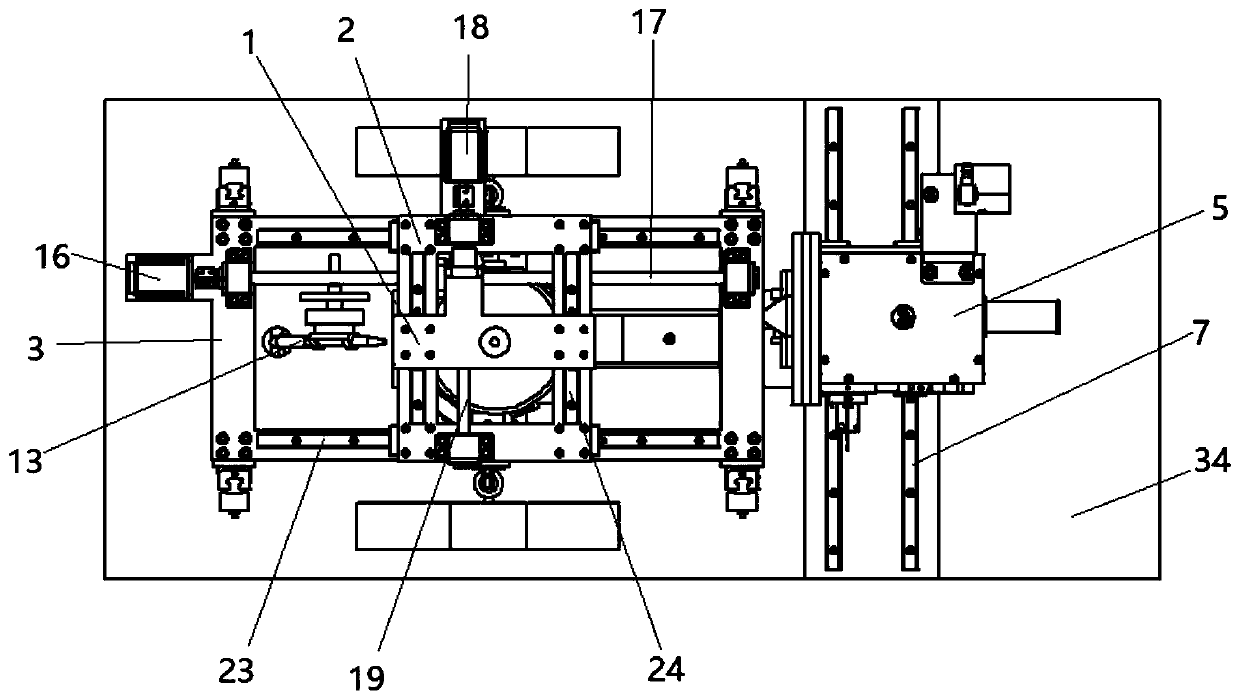

[0028] The invention provides a laser and magnetorheological fluid coupling polishing device (referred to as the device, see Figure 1-9 ), characterized in that the device comprises a laser transmitter 5, a laser rail 7, an electromagnet 11, a polishing wheel 12, a rotatable bracket 26, a laser rail slider 30, a base 34, a workpiece feeding device and a magnetorheological fluid circulation device ;

[0029] The workpiece feeding device includes fixture top beam 1, top support 2, Z-axis support 3, Z-axis main support frame 4, hydraulic rod 14, fixture 15, Z-axis support motor 16, Z-axis support ball screw 17, top support motor 18. Top bracket ball screw 19, column bracket 22, Z-axis bracket guide rail 23, top bracket guide rail 24, column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com