Anode for lithium secondary battery, lithium secondary battery comprising same, and manufacturing method therefor

A technology for lithium secondary batteries and negative electrodes, applied in the field of negative electrodes for lithium secondary batteries, lithium secondary batteries containing the same, and the preparation of the negative electrodes, capable of solving problems such as small capacity and achieving the effect of high capacity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

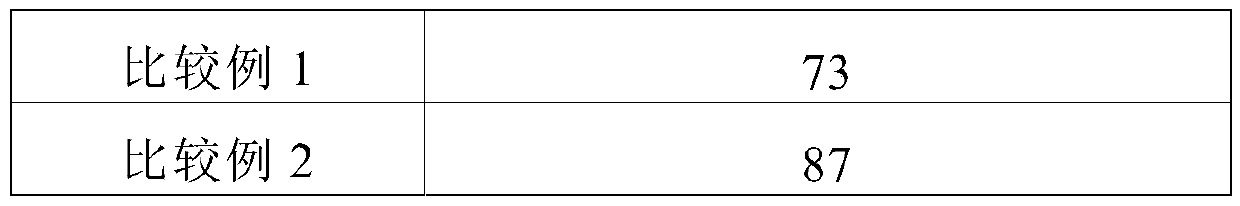

Examples

preparation example Construction

[0044] The method for preparing the negative electrode of the lithium secondary battery of the present invention comprises the following steps: (1) forming a negative electrode active material layer on the negative electrode current collector; and (2) forming a negative electrode active material layer containing lithium metal and metal oxide coating.

[0045] In step (1), as in a conventional method, an anode active material layer containing a carbon-based active material is formed on the anode current collector. For example, the negative electrode can be prepared according to a method of forming a negative electrode active material layer on a negative electrode current collector in which a slurry is prepared by mixing and stirring the negative electrode active material with a solvent and, if necessary, a binder and a conductive agent. After that, a negative electrode current collector was coated with the slurry, compressed, and then dried.

[0046] The negative active materi...

Embodiment 1

[0080]

[0081] By adding 92% by weight of SiO as the negative electrode active material, 3% by weight of Denka black (Denka black, conductive agent), 3.5% by weight of SBR (binder) and 1.5% by weight of CMC (thickener) into water to prepare negative electrode mixture slurry. After coating one surface of a copper current collector with the prepared negative electrode mixture slurry, drying and rolling, the coated copper current collector was punched into a predetermined size to prepare a negative electrode on which a negative electrode active material layer was formed.

[0082] A coating was formed on the negative electrode prepared above by physical vapor deposition. For this deposition, 90 parts by weight of lithium metal and 10 parts by weight of Al 2 o 3 As a raw material, it was placed in a thermal evaporator (Sunic System Company), and deposited on the SiO electrode with a thickness of 5 μm by thermal evaporation containing lithium metal and Al 2 o 3 coating.

[0...

Embodiment 2

[0086]

[0087] The negative electrode and the coin-type half cell were prepared in the same manner as in Example 1, except that lithium metal and Al were used in the preparation of the negative electrode in Example 1 in amounts of 95 parts by weight and 5 parts by weight, respectively. 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com