Light-enhancement type flexible supercapacitor and preparation method thereof

A supercapacitor and enhanced technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor collectors, etc., can solve the problem of few light-enhanced flexible supercapacitors, so as to facilitate transmission and avoid collapse , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

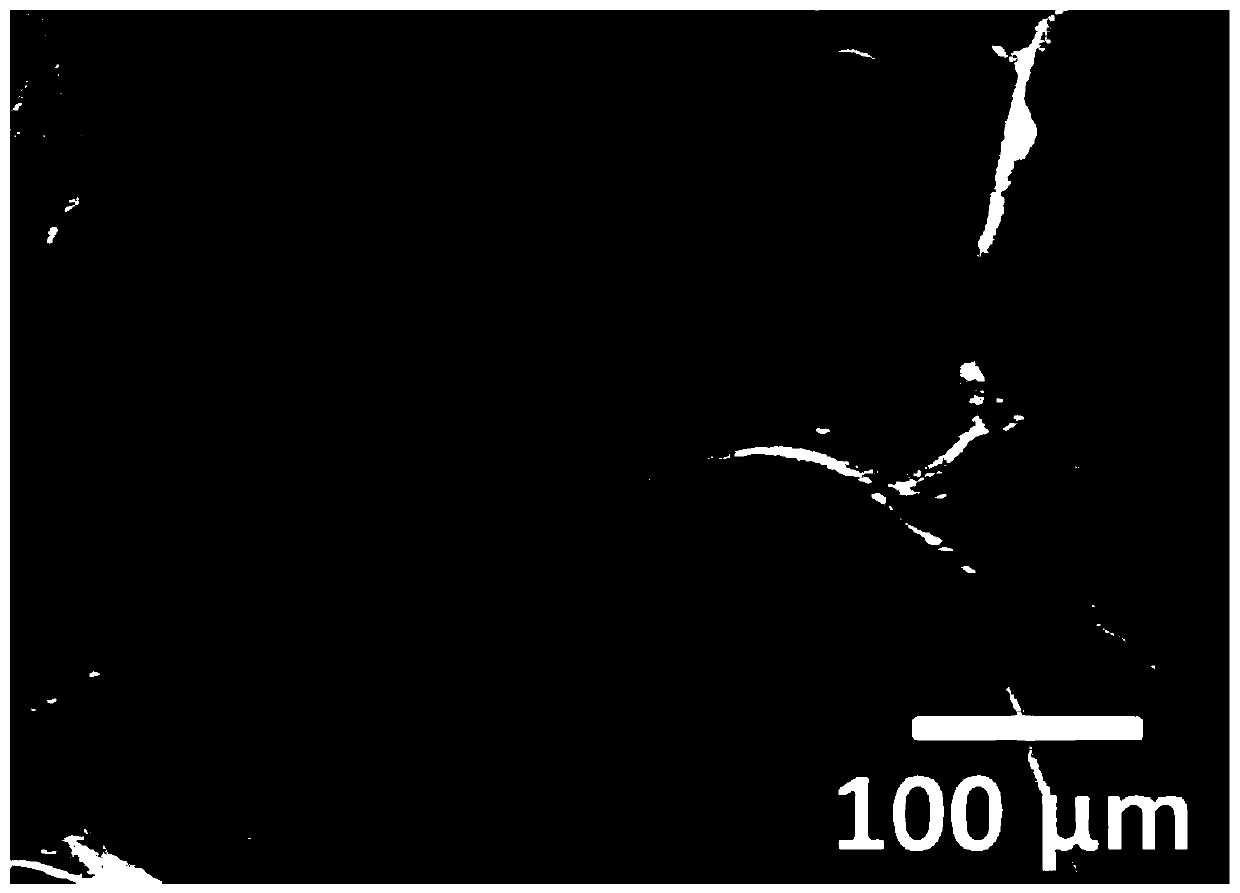

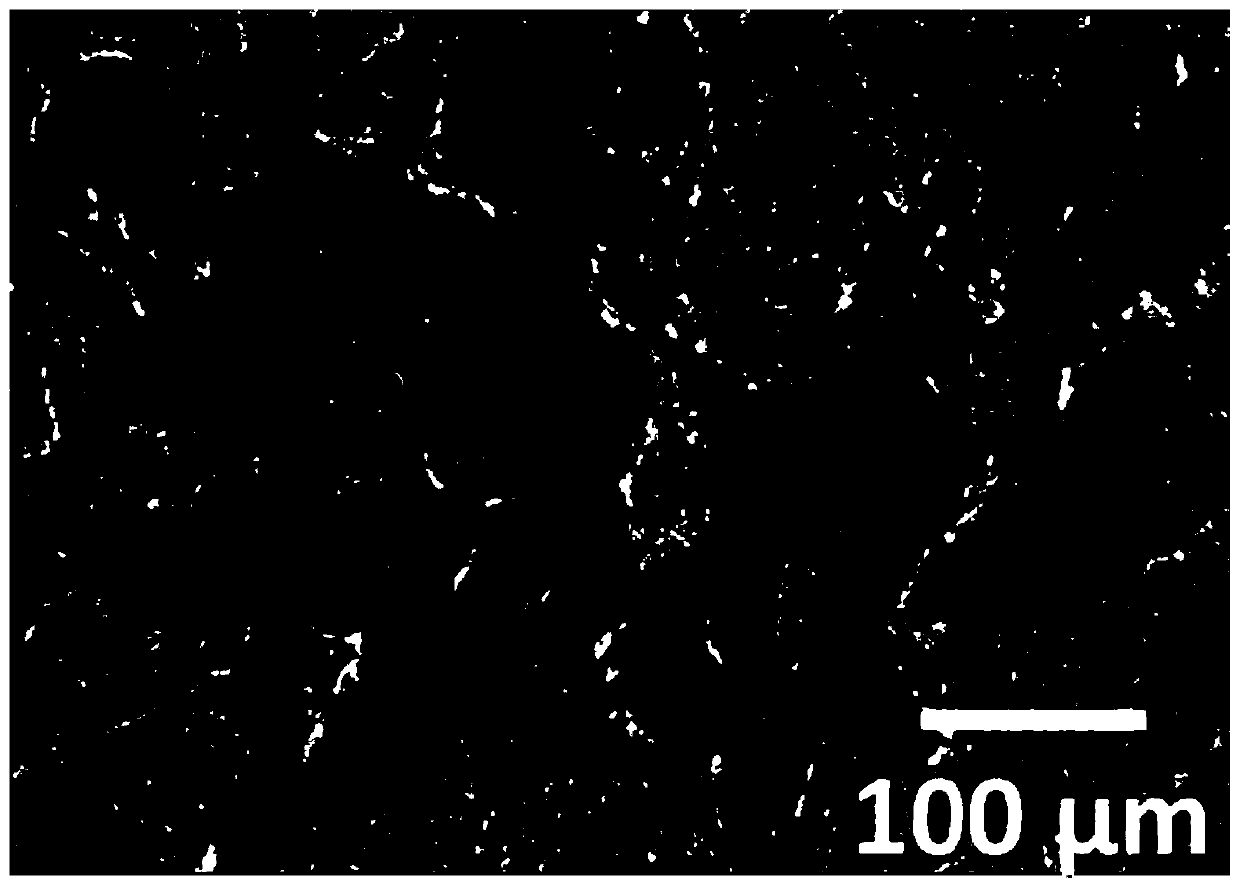

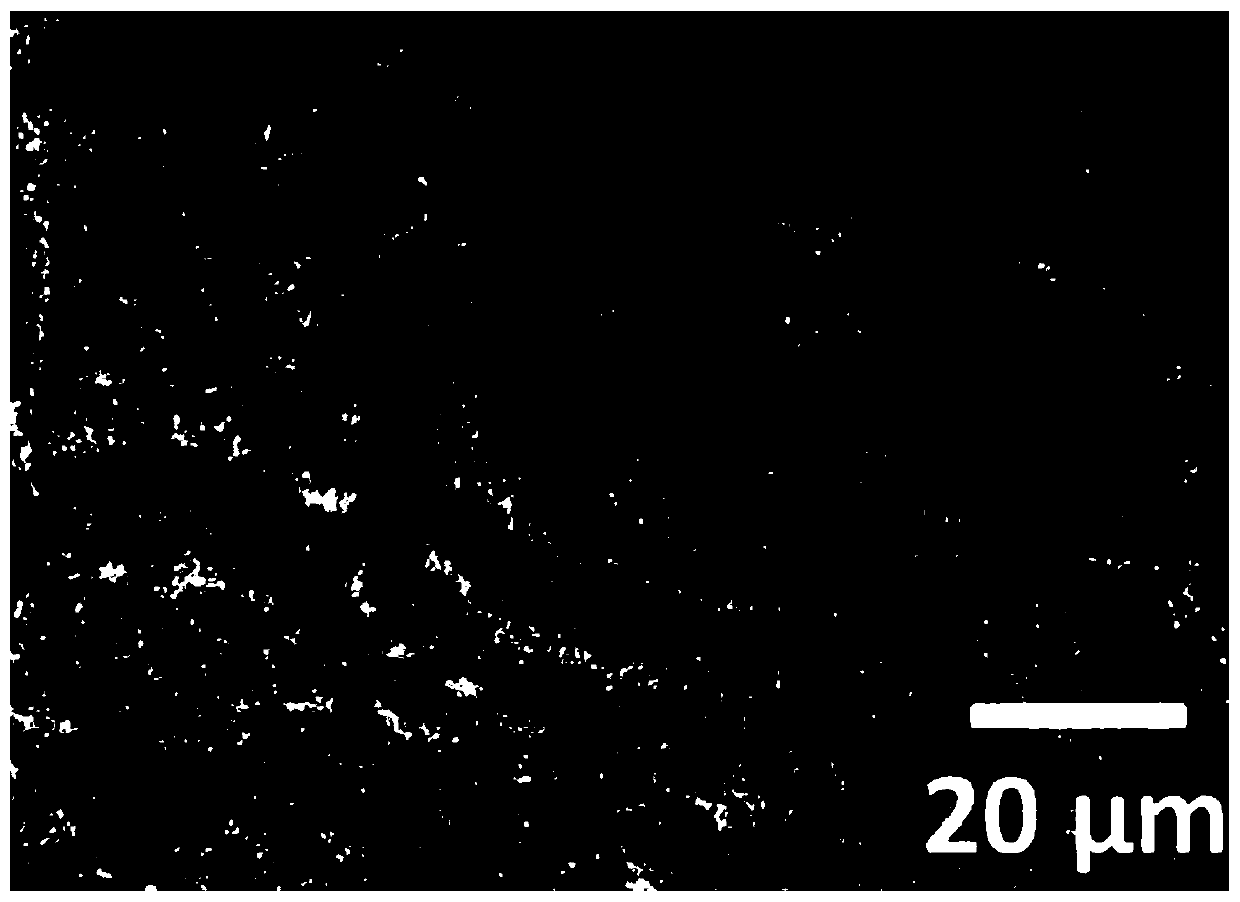

[0041] A light-enhanced flexible supercapacitor, the supercapacitor includes two electrode sheets and an electrolyte between the two electrode sheets, the electrode sheet is a flexible electrode sheet, and the flexible electrode sheet includes a polydimethylsiloxane base and is covered on Graphene / carbon nanotube / polyaniline composite material on one side of polydimethylsiloxane substrate, the electrolyte is polyvinyl alcohol / phosphoric acid hydrogel, coated on a flexible electrode sheet. The graphene / carbon nanotube / polyaniline composite material is covalently connected, and the mass percentage of polyaniline in the composite film is 0-30%. The mass ratio of polyvinyl alcohol and phosphoric acid in the polyvinyl alcohol / phosphoric acid hydrogel is 1:1, and the thickness of the coated gel is 5-10 μm.

[0042] A light-enhanced flexible supercapacitor and the specific steps for its preparation are:

[0043] (1) Using methane as the carbon source and a mixed gas of argon and hyd...

Embodiment 2

[0062] A light-enhanced flexible supercapacitor and the specific steps for its preparation are:

[0063] (1) Using methane as the carbon source and a mixed gas of argon and hydrogen as the carrier gas; wherein the volume ratio of argon to hydrogen in the carrier gas is 10:2, and the volume ratio of argon to methane is 40:5, The reaction temperature is 980°C, and graphene is grown by vapor deposition on the nickel foam substrate;

[0064] (2) the nickel foam is etched away with a mixed solution of ferric chloride and hydrochloric acid with a concentration ratio of 1:1 to obtain a graphene foam with a thickness of 1.0 mm;

[0065] (3) Add 0.003g of polyvinyl alcohol into 10mL of deionized water, swell at room temperature for 12 hours, heat and stir for 2 hours, add 1.212g of ferric nitrate and 1.125g of aluminum nitrate after cooling the solution, and stir until completely dissolved. The graphene foam is completely soaked in the catalyst solution, taken out and put into an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com