Method for synthesizing low-conductivity amide compound aqueous solution

A technology of amide compound and synthesis method, which is applied in the field of synthesis of low-conductivity amide compound aqueous solution, can solve the problems of long reaction time, high product conductivity, high post-processing cost, etc., and meet the needs of high-end customers and low impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

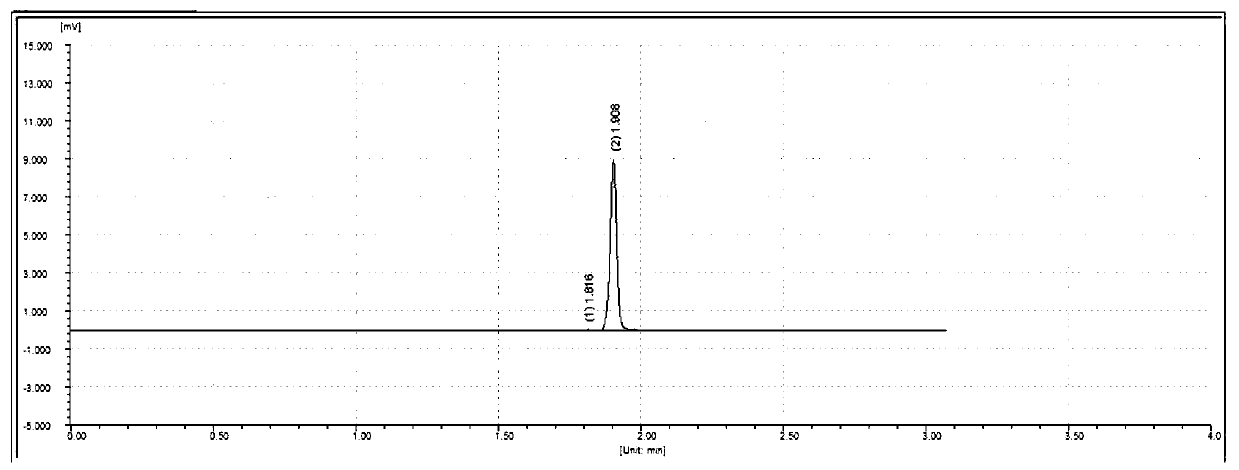

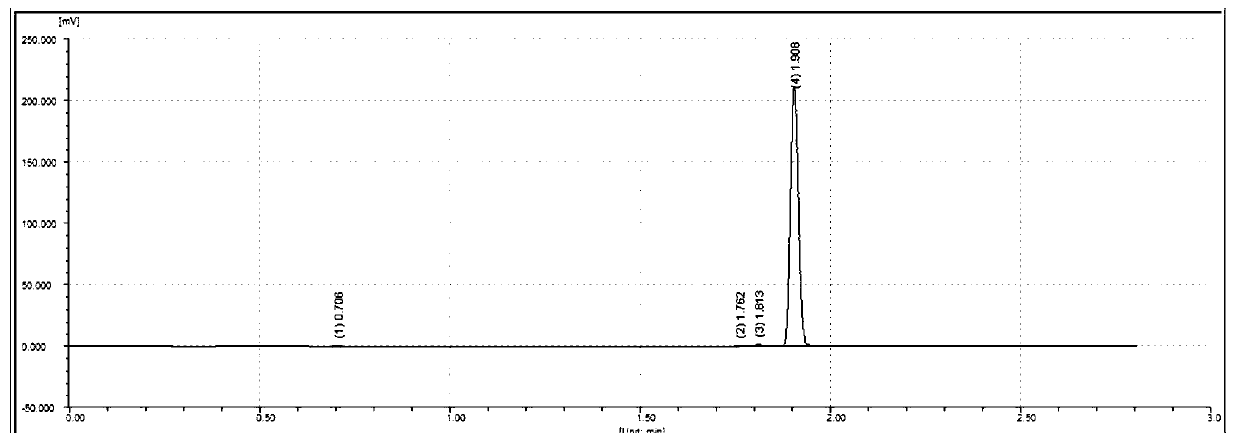

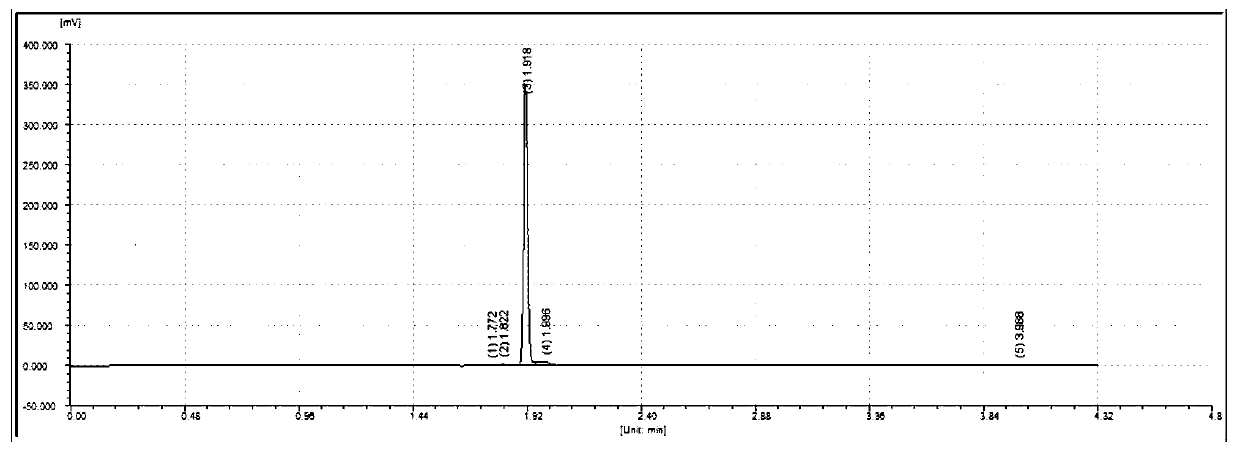

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a method for synthesizing an aqueous solution of a low-conductivity amide compound, which includes the following steps:

[0030] In a solution system in which a biocatalyst with nitrile hydratase activity exists, the corresponding amide compound is synthesized from the nitrile compound, and the temperature during the synthesis process is 9-14°C.

[0031] The embodiment of the present invention provides a method for synthesizing an aqueous solution of a low-conductivity amide compound. The corresponding amide compound is synthesized from a nitrile compound in the presence of a biocatalyst with nitrile hydratase activity, and the temperature during the reaction is controlled to be 9-14°C The inventors found that: when the temperature is lower than 9-14°C, the enzyme activity in the biocatalyst with nitrile hydratase activity is lower, and the yield of the resulting aqueous solution of amide compound is smaller. When the temperatu...

Embodiment 1

[0048] A 42% acrylamide aqueous solution is planned to synthesize 500g. It needs 156.8g of acrylonitrile as raw materials, 343.2g of pure water, and the pH is controlled within the range of 7.0-7.5.

[0049] (1) Pour 62-68 parts by weight of water into a 500ml four-necked flask. Use an electronic balance to weigh the planned amount of acrylonitrile and pour it into a 100ml cylindrical separatory funnel for later use. Install experimental equipment;

[0050] (2) Turn on the electric mixer and set the speed to 60-80r / min;

[0051] (3) Use a pH meter to measure the pH of pure water, and add 8%-12% NaOH solution to adjust the pH to 7.5-8.0;

[0052] (4) Add 0.15-0.4 parts by weight of Nocardia to a 500ml volumetric flask;

[0053] (5) Add ice cubes to the water bath and cool down to 10-12°C in the experiment;

[0054] (6) After the bacteria are added and stirred for 8-12 minutes, the pH is measured, and the pH is controlled at 7.0-7.5. If it is not in this range, add an appropriate amount...

Embodiment 2

[0062] A 50% acrylamide aqueous solution is planned to synthesize 500g. The raw materials required are 187.0g of acrylonitrile, 313.0g of pure water, and the pH is controlled within the range of 7.0-7.5.

[0063] (1) Pour 62-68 parts by weight of water into a 500ml four-necked flask. Use an electronic balance to weigh the planned amount of acrylonitrile and pour it into a 100ml cylindrical separatory funnel for later use. Install experimental equipment;

[0064] (2) Turn on the electric mixer and set the speed to 60-80r / min;

[0065] (3) Use a pH meter to measure the pH of pure water, and add 8%-12% NaOH solution to adjust the pH to 7.5-8.0;

[0066] (4) Add 0.15-0.4 parts by weight of Nocardia to a 500ml volumetric flask;

[0067] (5) Add ice cubes to the water bath and cool down to 10-12°C in the experiment;

[0068] (6) After the bacteria are added and stirred for 8-12 minutes, the pH is measured, and the pH is controlled at 7.0-7.5. If it is not in this range, add an appropriate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com