Epoxy resin/ordered boron nitride composite material and preparation method thereof

A technology of epoxy resin and composite materials, which is applied in the field of composite materials to achieve the effect of simple and gentle preparation method and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

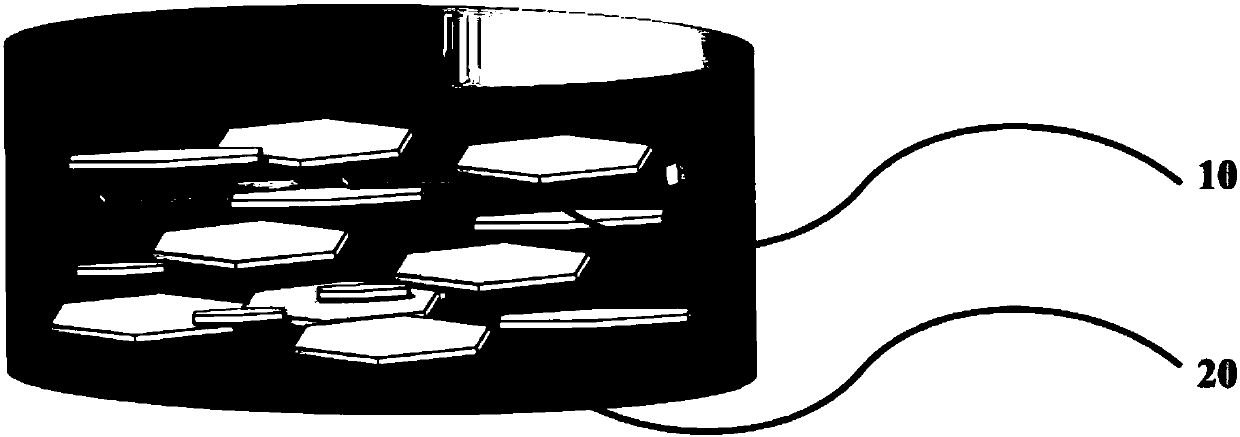

Image

Examples

preparation example Construction

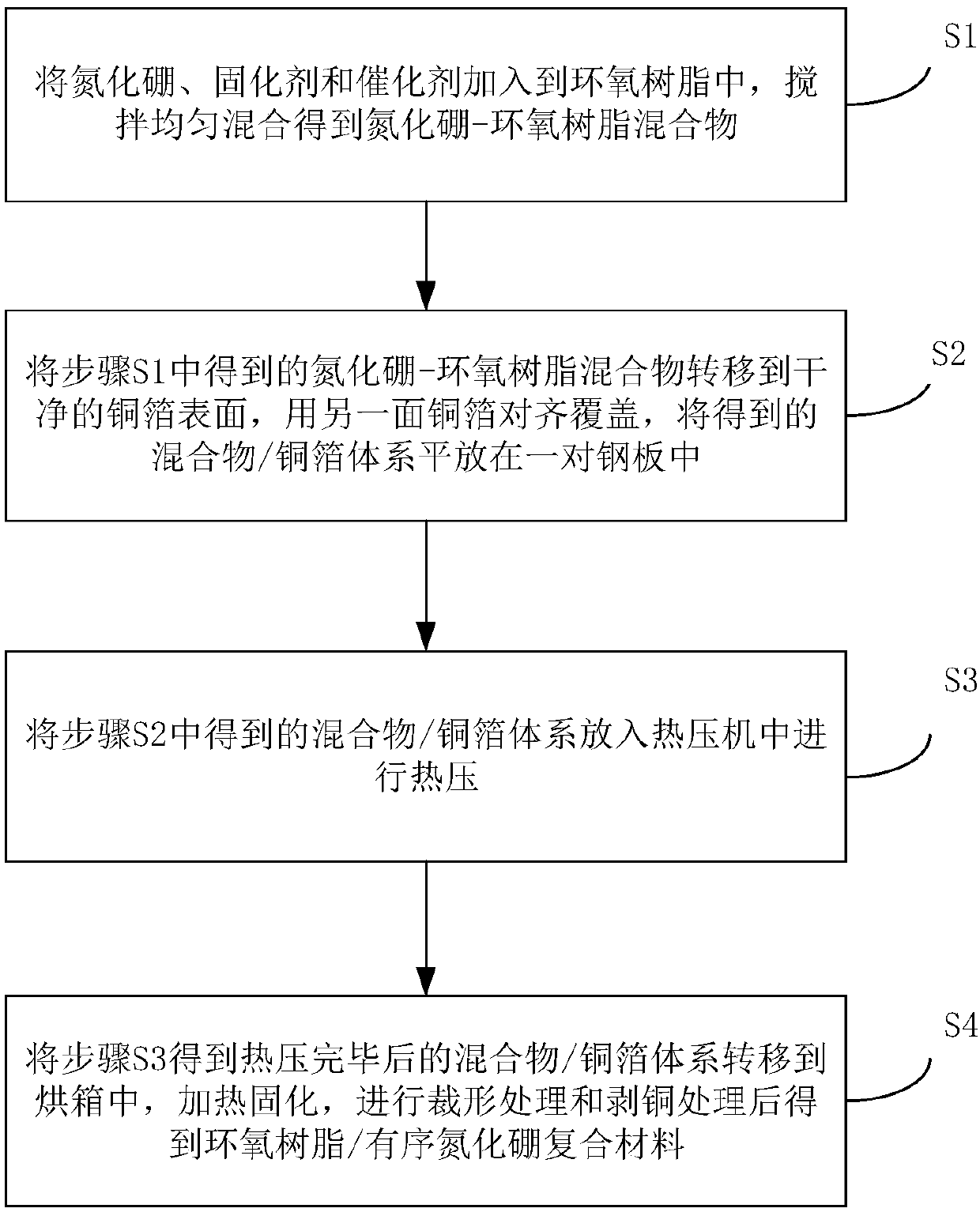

[0060] Such as image 3 As shown, the specific embodiment part of the present invention also provides a method for preparing the above-mentioned epoxy resin / ordered boron nitride composite material, the method comprising the following steps:

[0061] Step S1: adding boron nitride, curing agent and catalyst into the epoxy resin, stirring and mixing evenly to obtain a boron nitride-epoxy resin mixture;

[0062] Step S2: transfer the boron nitride-epoxy resin mixture obtained in step S1 to a clean copper foil surface, align and cover it with another copper foil, and place the obtained mixture / copper foil system flatly in a pair of steel plates;

[0063] Step S3: putting the mixture / copper foil system obtained in step S2 into a hot press for hot pressing;

[0064] Step S4: transfer the hot-pressed mixture / copper foil system obtained in step S3 to an oven, heat and solidify, and perform shape cutting and copper stripping to obtain an epoxy resin / ordered boron nitride composite mat...

Embodiment 1

[0067] A preparation method of epoxy resin / ordered boron nitride composite material, said method comprising the following steps:

[0068] (1) Add 2g of boron nitride with a size of 2μm, 0.5g of methyl hexahydrophthalic anhydride and 0.05g of N,N-dimethylbenzylamine into 10g of epoxy resin, and mix by ball milling at 200rpm for 1h to obtain boron nitride- epoxy resin mixture;

[0069] (2) Transfer the boron nitride-epoxy resin mixture system of step (1) to a clean copper foil surface, align and cover it with another copper foil, and place the obtained mixture / copper foil system flatly in a pair of steel plates;

[0070] (3) Put the system in step (2) into a hot press, and perform hot pressing at 7MPa and 120°C;

[0071] (4) Transfer the hot-pressed mixture / copper foil system obtained in step (3) to an oven, heat and solidify, and obtain an epoxy resin / ordered boron nitride composite material after cutting and stripping copper, and then heat it at 140°C , 160° C., and 210° C. ...

Embodiment 2

[0074] A preparation method of epoxy resin / ordered boron nitride composite material, said method comprising the following steps:

[0075] (1) Add 4g of boron nitride with a size of 10μm, 1.5g of methyl hexahydrophthalic anhydride and 0.15g of N,N-dimethylbenzylamine into 10g of epoxy resin, and stir evenly at 300rpm for 1h to obtain boron nitride- epoxy resin mixture;

[0076] (2) Transfer the boron nitride-epoxy resin mixture system of step (1) to a clean copper foil surface, align and cover it with another copper foil, and place the obtained mixture / copper foil system flatly in a pair of steel plates;

[0077] (3) Put the system in step (2) into a hot press, and perform hot pressing at 10MPa and 150°C;

[0078] (4) Transfer the hot-pressed mixture / copper foil system obtained in step (3) to an oven, heat and solidify, and obtain an epoxy resin / ordered boron nitride composite material after cutting and stripping copper, and then heat it at 140°C , 160° C., and 210° C. for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com