Low temperature resistant nitrile rubber and preparation method thereof

A technology of nitrile rubber and low temperature resistance, which is applied in the field of organic polymer compounds, which can solve the problems of restricting the use of nitrile rubber and poor cold resistance, and achieve the effects of improving low temperature resistance, ensuring uniformity, and meeting the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

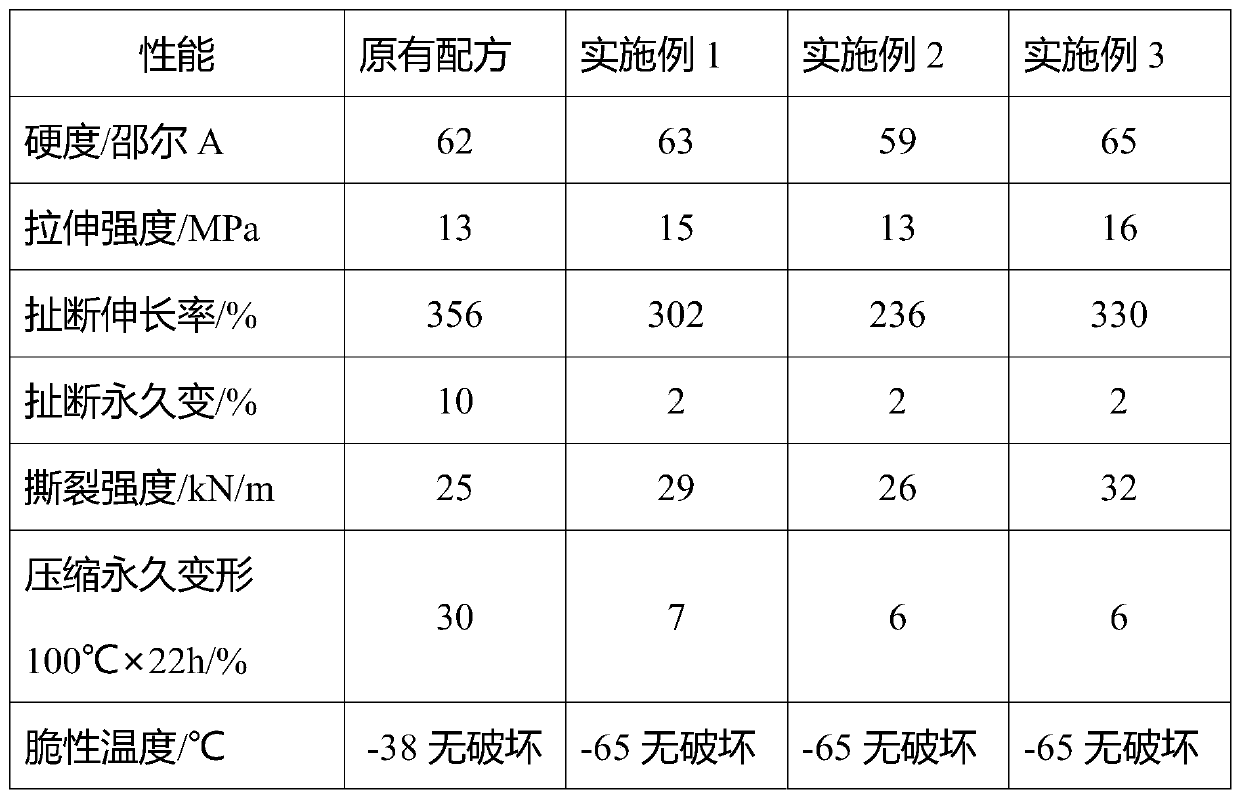

Examples

Embodiment 1

[0017] A kind of low-temperature resistant nitrile rubber, prepared from the following formula by weight: 100 parts of nitrile rubber 1865, 40 parts of natural gas semi-reinforced carbon black, 40 parts of high wear-resistant carbon black N330, 1.5 parts of peroxide diiso Propylbenzene, 6 parts of indirect zinc oxide, 1 part of stearic acid, 0.25 parts of sulfur, 1.2 parts of dibenzothiazole dithio, 0.2 parts of tetramethylthiuram disulfide, 20 parts of plasticizer TP-90, 1 part of anti-aging agent N-isopropyl-N'-phenyl-p-phenylenediamine, 1 part of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer.

[0018] The present invention also discloses a preparation method based on the above-mentioned low-temperature resistant nitrile rubber, comprising the following steps,

[0019] Step S1: After the nitrile rubber is kept at a constant temperature of 35-45°C, it is masticated on an open mill.

[0020] Step S2: Add other formula components into the open mill, knead evenl...

Embodiment 2

[0023] This embodiment is prepared from the following formula by weight: 100 parts of nitrile rubber, 50 parts of natural gas semi-reinforced carbon black, 30 parts of high wear-resistant carbon black, 1.7 parts of dicumyl peroxide, 5 parts of indirect method Zinc oxide, 1.2 parts of stearic acid, 0.3 parts of sulfur, 1.2 parts of dithiodibenzothiazole, 0.25 parts of tetramethylthiuram disulfide, 23 parts of plasticizer, 2 parts of anti-aging agent N-isopropyl- N'-phenyl-p-phenylenediamine, 1 part anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer. The preparation method is the same as that of Example 1, and will not be repeated here.

Embodiment 3

[0025] This embodiment is prepared from the following formula by weight: 100 parts of nitrile rubber, 55 parts of natural gas semi-reinforced carbon black, 35 parts of high wear-resistant carbon black, 1.75 parts of peroxide Dicumylbenzene, 4.5 parts of indirect zinc oxide, 1 part of stearic acid, 0.35 parts of sulfur, 1.2 parts of dithiodibenzothiazole, 0.1 part of tetramethylthiuram disulfide, 22 parts of plasticizer, 1.5 parts of antiaging agent N-isopropyl-N'-phenyl-p-phenylenediamine, and 1 part of antiaging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer. The preparation method is the same as that of Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com