Method for preparing cotton-based porous biomass carbon

A technology of biomass carbon and cotton, applied in carbon preparation/purification, active material electrodes, electrochemical generators, etc., can solve the problems of low initial charge and discharge efficiency, poor long-term cycle performance, etc., and achieve excellent electrochemical performance , improve the utilization rate, and facilitate the effect of infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Take 0.5 g of cotton, wash it with distilled water, and dry it. In the drying, the temperature is raised at a heating rate of 1 °C / min, and then at a heating rate of 4 °C / min. The temperature is raised to 60 °C and then dried at a constant temperature to obtain Product A;

[0032] 2) Mix product A and zinc chloride at a mass ratio of 1:3 and grind in a mortar for 30 min to obtain product B;

[0033] 3) Spread the product B in a white alumina porcelain boat, place it in a tube furnace with a nitrogen atmosphere and raise the temperature to 1000 °C at a heating rate of 2 °C / min, keep it for 2 hours, and obtain the product C after natural cooling;

[0034] 4) Soak product C in 50ml of 2mol / L hydrochloric acid solution at 60°C for 24 hours to obtain product D;

[0035] 5) The product D was repeatedly washed with distilled water until pH = 7, and dried at 60°C to obtain a cotton-based porous biomass carbon material.

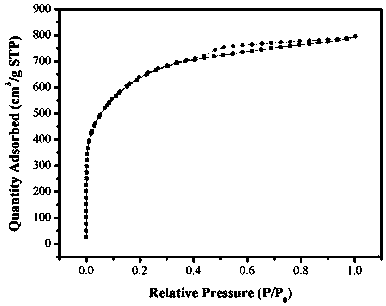

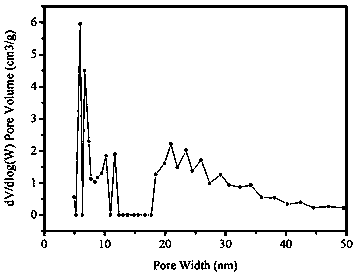

[0036] After testing, the specific surface area of ...

Embodiment 2

[0038] 1) Take 0.5 g of cotton, wash it with distilled water, and dry it. In the drying process, the temperature is raised at a heating rate of 2 °C / min, and then at a heating rate of 5 °C / min. The temperature is raised to 70 °C and then dried at a constant temperature to obtain Product A;

[0039] 2) Mix product A and zinc chloride at a mass ratio of 1:4 and grind in a mortar for 30 minutes to obtain product B;

[0040] 3) Spread the product B in a white alumina porcelain boat, place it in a tube furnace with a nitrogen atmosphere and raise the temperature to 1000 °C at a heating rate of 2 °C / min, keep it for 2 hours, and obtain the product C after natural cooling;

[0041] 4) Soak product C in 50ml of 2mol / L hydrochloric acid solution at 60°C for 24 hours to obtain product D;

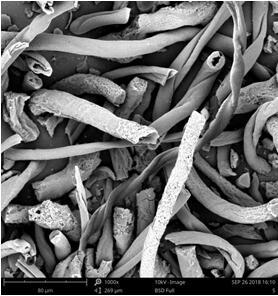

[0042] 5) The product D was repeatedly washed with distilled water until pH = 7, and dried at 60°C to obtain a cotton-based porous biomass carbon material (SEM image shown in figure 1 shown).

[00...

Embodiment 3

[0045] 1) Take 0.5 g of cotton, wash it with distilled water, and dry it. In the drying process, the temperature is raised at a rate of 3 °C / min, and then at a rate of 6 °C / min. The temperature is raised to 80 °C and then dried at a constant temperature to obtain Product A;

[0046] 2) Mix product A and zinc chloride at a mass ratio of 1:5 and grind in a mortar for 30 minutes to obtain product B;

[0047] 3) Spread the product B in a white alumina porcelain boat, place it in a tube furnace with a nitrogen atmosphere and raise the temperature to 1000 °C at a heating rate of 2 °C / min, keep it for 2 hours, and obtain the product C after natural cooling;

[0048] 4) Soak product C in 50ml of 2mol / L hydrochloric acid solution at 60°C for 24 hours to obtain product D;

[0049] 5) The product D was repeatedly washed with distilled water until pH = 7, and dried at 60°C to obtain a cotton-based porous biomass carbon material.

[0050] After testing, the specific surface area of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com