Supporting plate lifting device for mold shell chain injection machine

A technology of chain injection machine and pallet, which is applied in the direction of conveyor objects, transportation and packaging, etc., which can solve the problems of difficult production, increased equipment cost, and large frictional resistance, so as to increase the ability to flexibly carry pallets and reduce equipment loss , The effect of increased seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

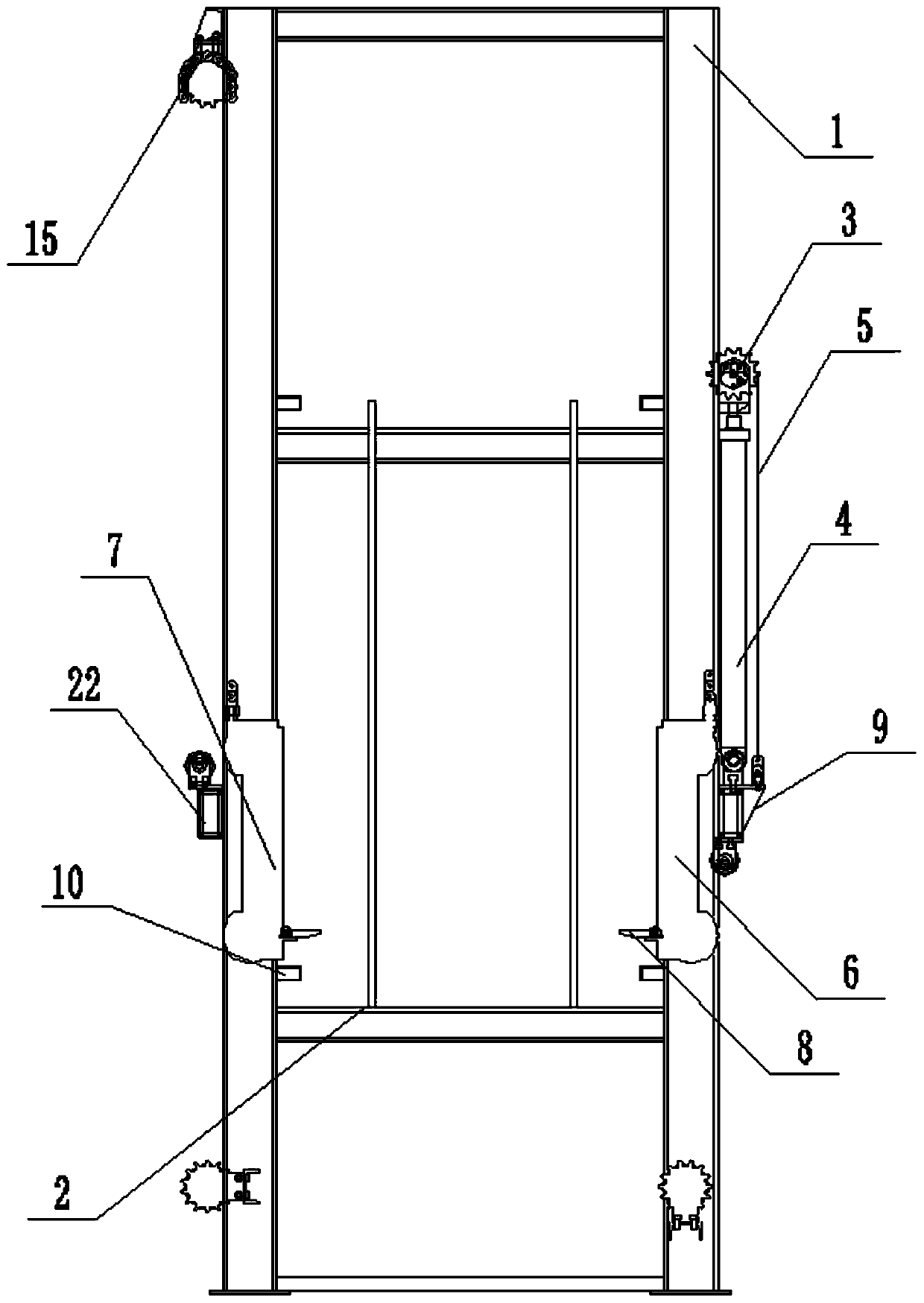

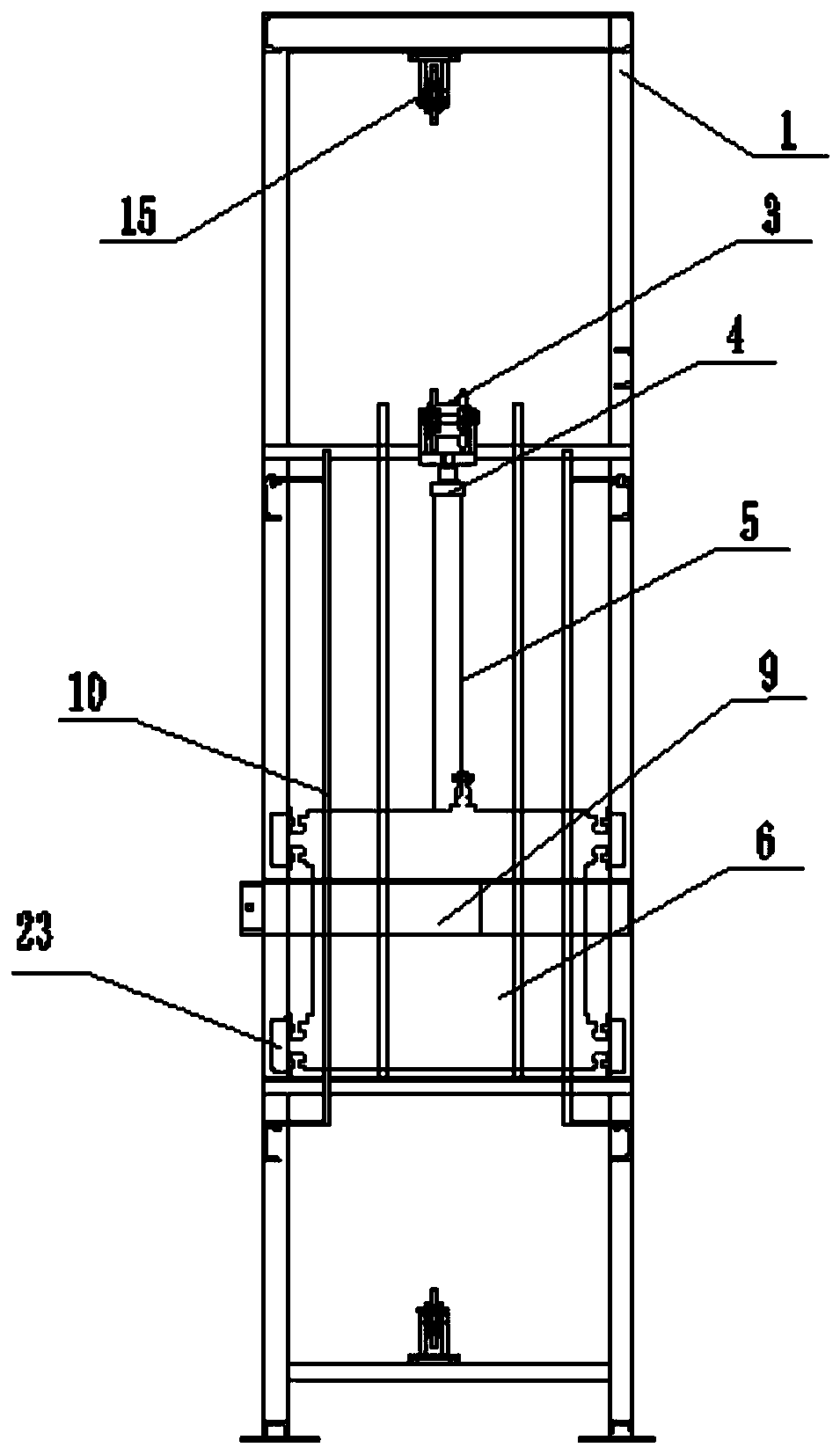

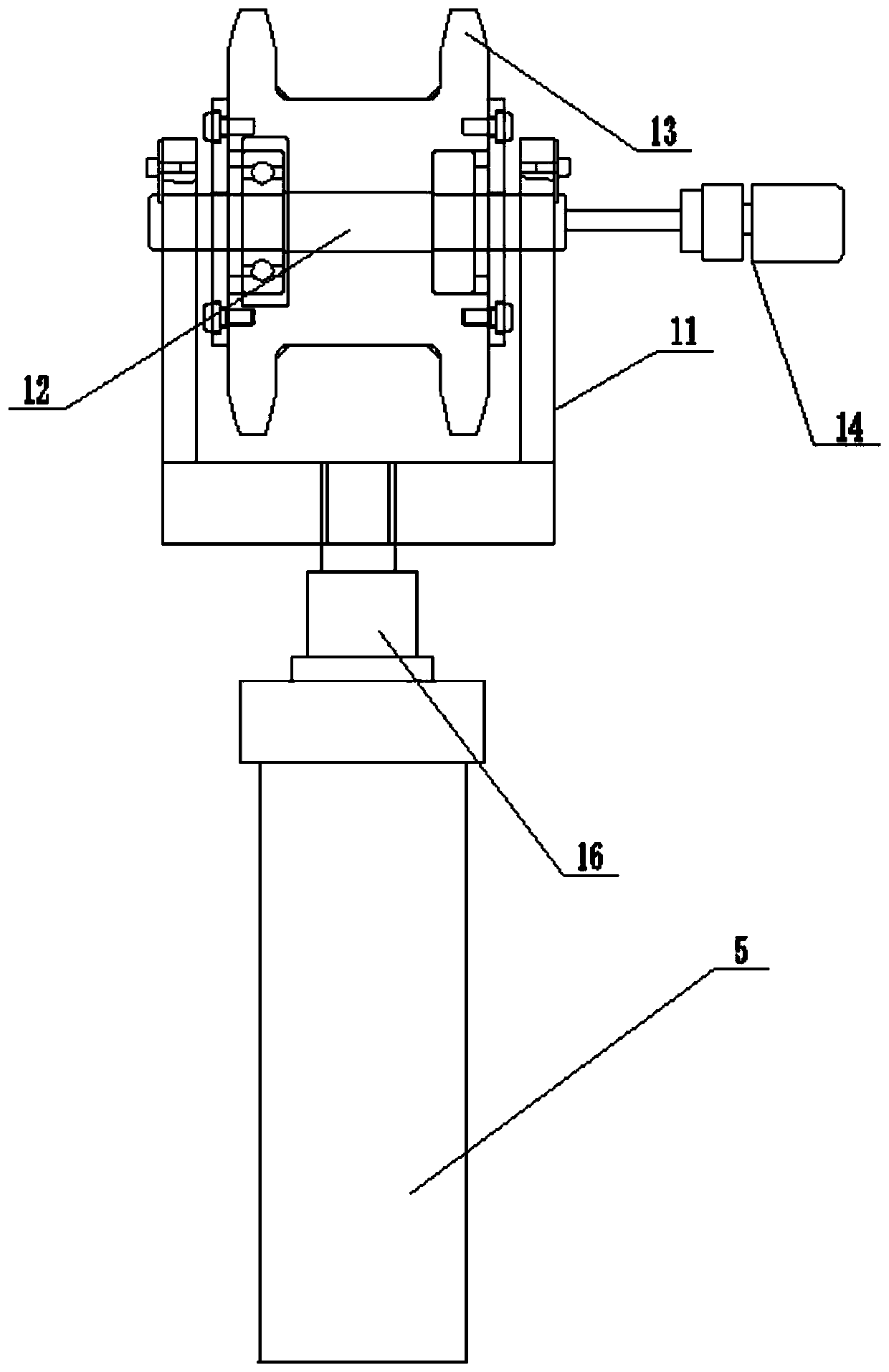

[0024] A pallet lifting device for a formwork chain injection machine, comprising a lifting frame 1 and a pallet stack 2, the pallet stack 2 is located at the bottom of the lifting frame 1, and both sides of the lifting frame 1 are connected with a double sprocket assembly 3 and a driven sprocket assembly , the hydraulic cylinder 4 is installed on the side of the lifting frame 1, the hydraulic cylinder 4 is connected with the double sprocket assembly 3, the double sprocket assembly 3 is connected with the sleeve roller chain 5, and the sleeve roller chain 5 and the double sprocket assembly 3 pass through the sleeve The roller chain 5 is connected to the lifting trolley Ⅰ6 by transmission, and the sleeve roller chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com