Flexible straight valve tower valve base main water pipe and optical cable groove efficient installation device and installation method

A technology of installation device and main water pipe, which is applied in the directions of optical fiber/cable installation, optics, light guide, etc., can solve the problems of inability to install the lower components, high rental cost of climbing cars, and high risk factor, and achieves simple structure, low cost, and reliable bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

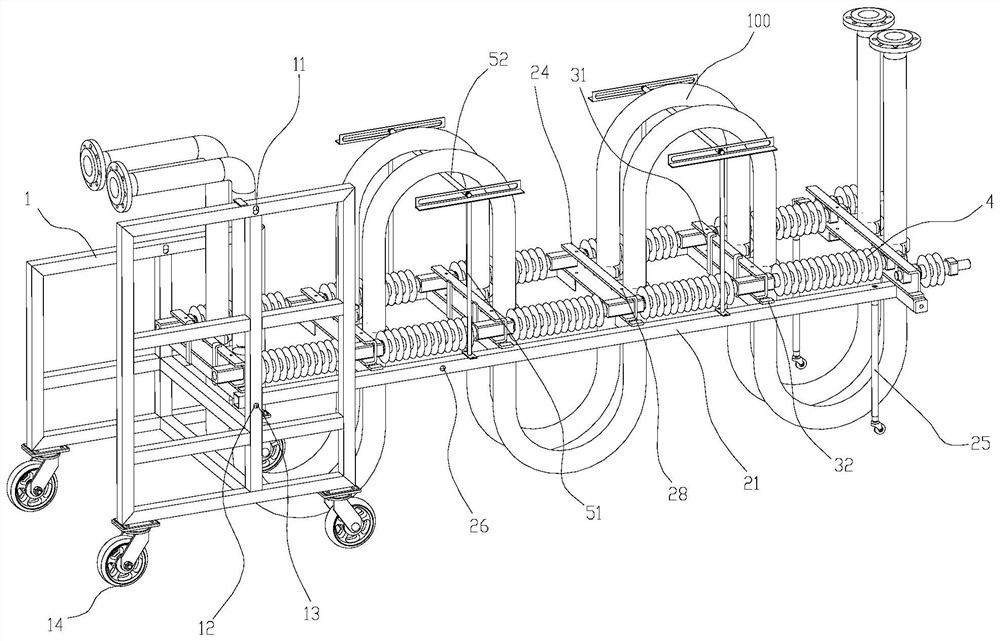

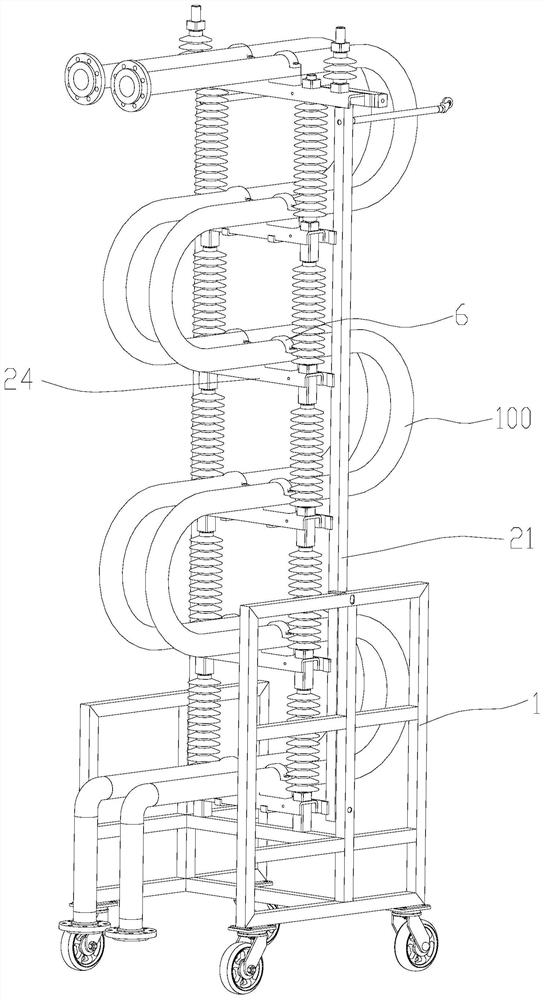

[0033] Such as figure 1 and figure 2 As shown, this embodiment provides an efficient installation device for the main water pipe of the valve base of the flexible straight valve tower and the cable channel, including a mobile base 1 , a mounting frame, a positioning component and a plurality of pull rod insulators 4 .

[0034] Such as figure 1 and figure 2 As shown, the installation frame includes two support rods 21, a plurality of connecting rods 22, a plurality of mounting blocks 23 and a plurality of installation beams 24, and a plurality of connecting rods are located between the two supporting rods, and the two ends of the connecting rods are respectively connected to the two Two supporting rods are connected, and multiple mounting blocks are respectively connected to the supporting rods. Every two oppositely arranged mounting blocks constitute a set of mounting parts, and each group of mounting parts is located between two adjacent connecting rods; multiple mounting...

Embodiment 2

[0047] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the high-efficiency installation device for the flexible straight valve tower valve base main water pipe and optical cable trough of this embodiment also includes an adapter plate, and the adapter plate includes first plate bodies 71 and The second plate body 72, the first plate body is connected to the optical cable groove 200 through bolts, and the second plate body is connected to the installation beam through bolts. Two fiber optic cable trays can be installed at one time on the mounting bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com