A packaging line and process for improving the accumulation ratio of powdery materials

A technology for packaging lines and powdery materials, applied in the field of packaging lines, can solve the problems of splashing powdery materials, wasting packaging materials, and wasting the use space of packaging bags, and achieves improved filling stability, stable filling process, and improved packaging. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

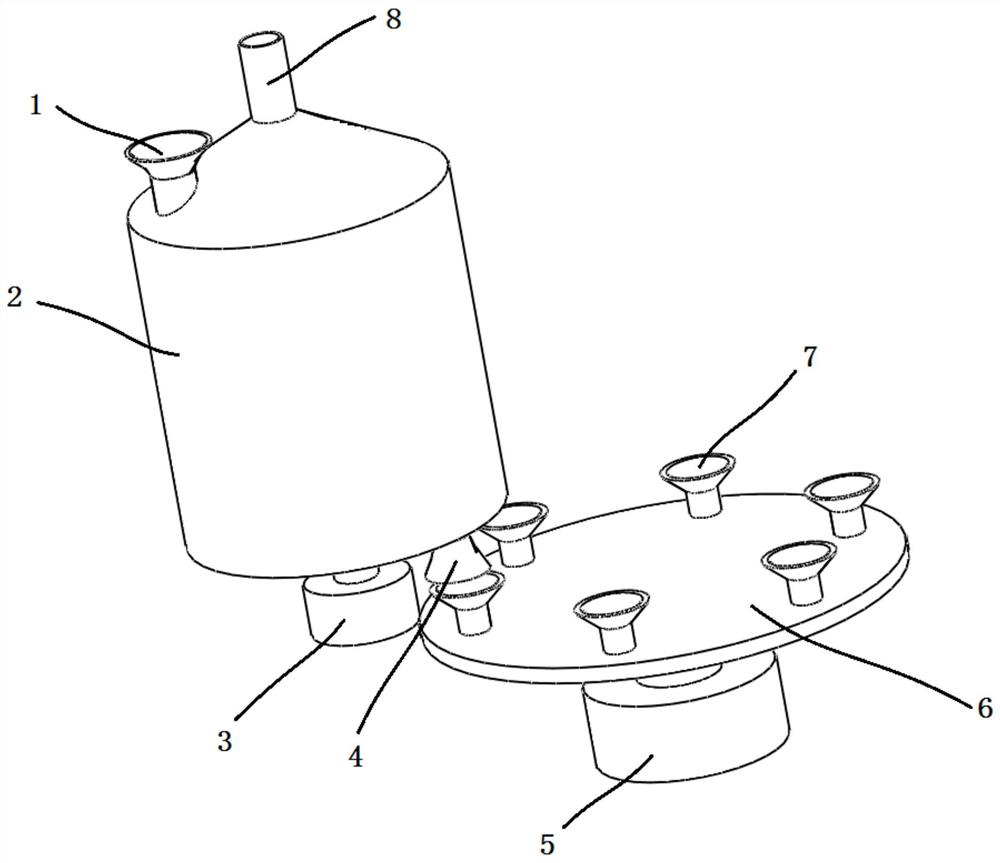

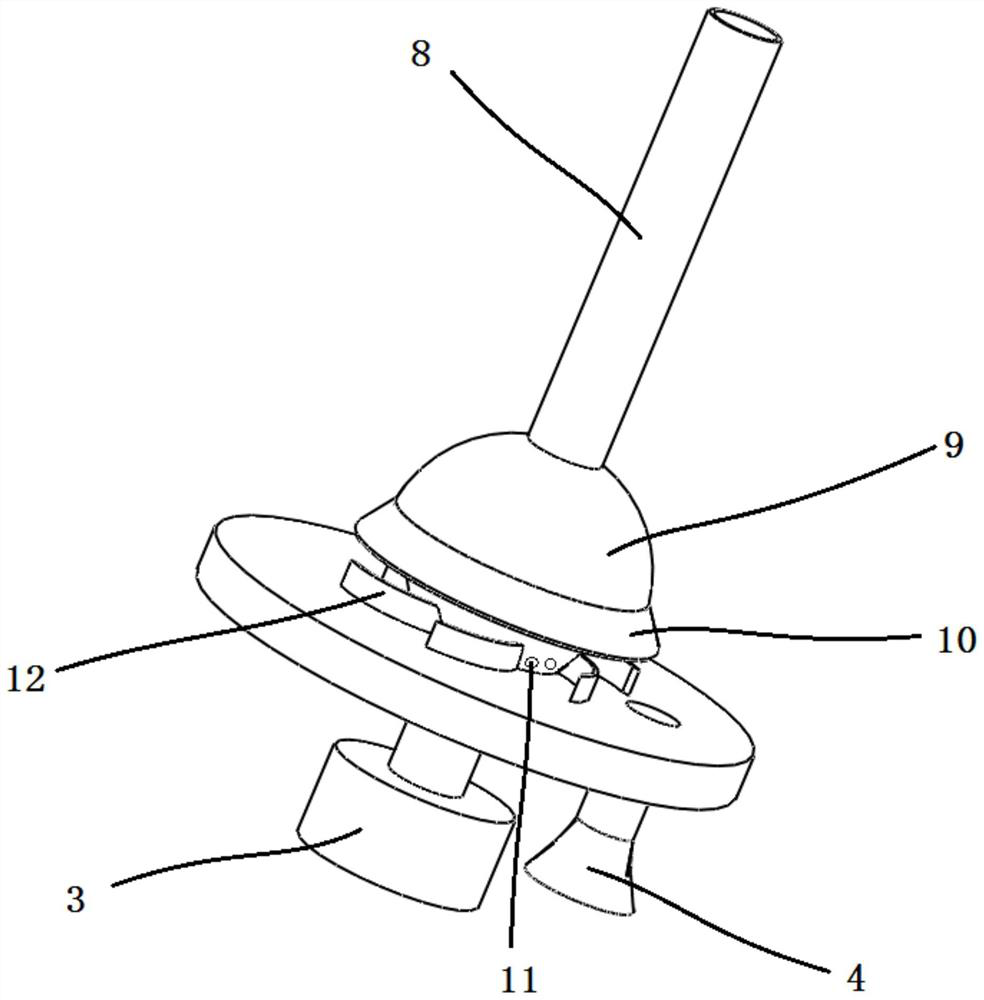

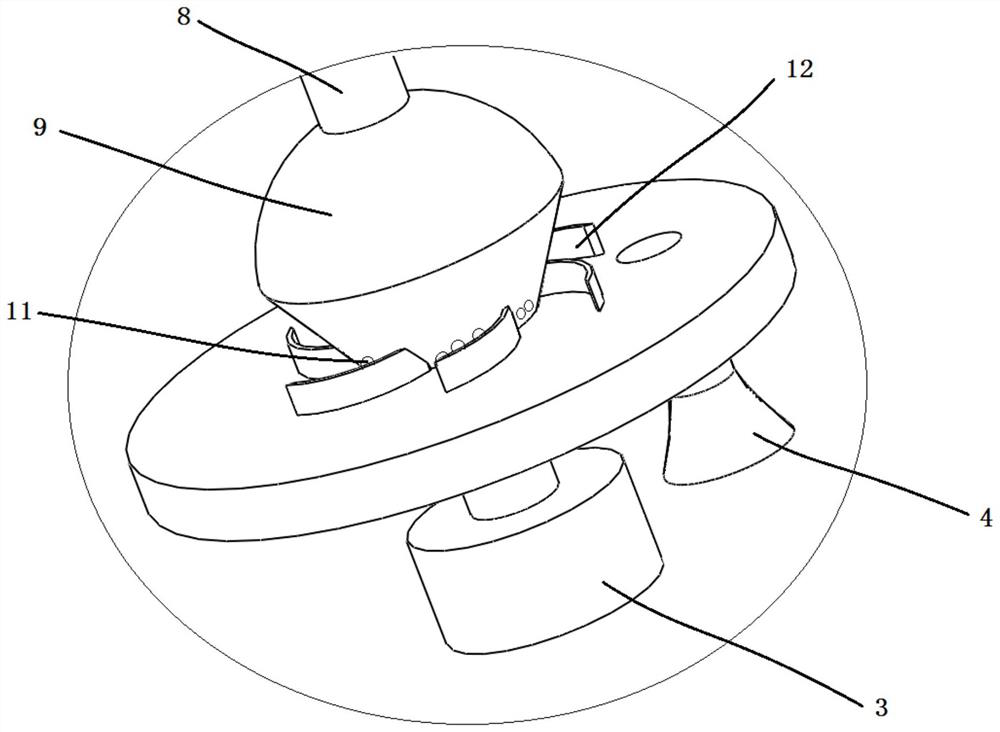

[0032] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0033] Such as Figure 1-3 As shown, a packaging line that improves the accumulation ratio of powdery materials includes: a material chamber 2, an extruding part 9 installed inside the material chamber 2, and a filling assembly located below the material chamber 2; the extruding part 9 Can be rotated, the upper side of the outer wall of the extruded part 9 is provided with a guard plate 10 along the circumferential direction, and the lower side of the outer wall of the extruded part 9 is provided with several extruded plates 12 along the circumferential direction; the outer wall of the extruded part 9 is located at Several air extraction hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com