Vertical steel pipe welding, grinding and polishing robot

A robot and steel pipe technology, applied in grinding/polishing equipment, surface-polished machine tools, grinding racks, etc., can solve the problems of high labor intensity, cumbersome steps, inability to realize welding function, etc., and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

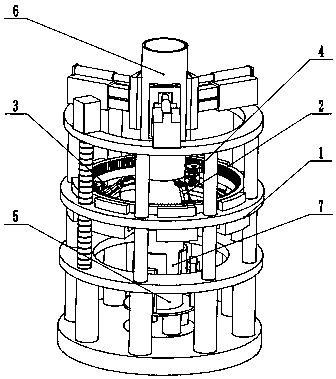

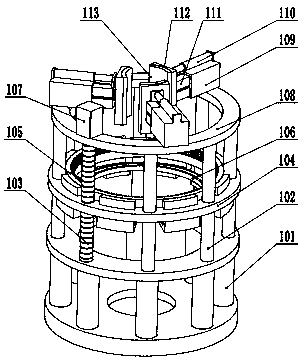

[0043] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 6 , Figure 8 , Figure 9 As shown, a vertical steel pipe welding, grinding and polishing robot includes a body part 1, a welding part 2, a grinding part 3, a polishing part 4, and a base part 5;

[0044] Body part 1 comprises: bottom support 101, lifting guide rail 102, lifting screw mandrel 103, lifting disc 104, inner ring gear 105, ring moving guide rail 106, first stepping motor 107, top ring 108, outer telescopic sleeve 109, first Electric cylinder 110, inner telescopic block 111, top block 112, fixed sleeve 113;

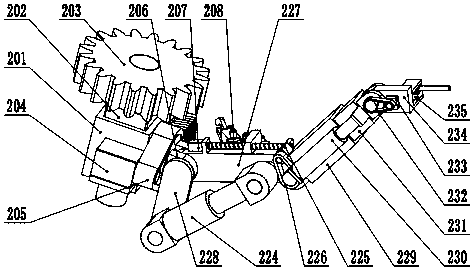

[0045] The welding part 2 includes: a first ring moving block 201, a second stepping motor 202, a first gear 203, a third stepping motor 204, a first transmission belt 205, a first rotating block 206, a fourth stepping motor 207, a telescopic Screw mandrel 208, mobile take seat 209, side turning bar 210, the second transmission belt 211, the first two-way asynchronous motor 212, the third ...

Embodiment 2

[0049] Embodiment 2: the remainder of this embodiment is the same as the previous embodiment, wherein as figure 2 As shown, one end of the lifting guide rail 102 is fixedly installed on the bottom support 101, the other end is fixedly installed on the top ring 108, the first stepping motor 107 is fixedly installed on the top ring 108, and one end of the lifting screw 103 is fixedly installed on the first step On the motor 107, the other end is installed in rotation with the bottom support 101, the lifting plate 104 and the lifting screw 103 are driven by threads, and are slidably installed with the lifting guide rail 102, and the inner ring gear 105 and the ring moving guide rail 106 are fixedly installed on the lifting plate 104. The outer telescopic sleeve 109 is fixedly installed on the top ring 108, the inner telescopic block 111 is slidably installed with the outer telescopic sleeve 109, the bottom of the first electric cylinder 110 is fixedly installed with the outer tel...

Embodiment 3

[0050] Embodiment 3: the remainder of this embodiment is the same as the previous embodiment, wherein as image 3 , Figure 4 , Figure 5 As shown, the second stepping motor 202 and the third stepping motor 204 are fixedly installed on the first ring moving block 201, the first ring moving block 201 and the ring moving guide rail 106 are slidably installed, and the first gear 203 is fixedly installed on the second ring moving block 201. On the stepping motor 202, the first gear 203 meshes with the ring gear 105, the first rotating block 206 and the first ring moving block 201 are installed in rotation through rolling bearings, and the first transmission belt 205 is wound around the third stepping motor 204 and the first rotating block. Outside the block 206, the fixed arm 228 is fixedly installed on the first rotating block 206, the big arm 227 is rotatably installed with the first rotatable block 206, one end of the second electric cylinder 224 is rotatably installed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com