A main keel welding equipment and welding method

A welding equipment and welding method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large footprint and low efficiency, achieve small footprint, easy large-scale industrialization, and improve welding The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

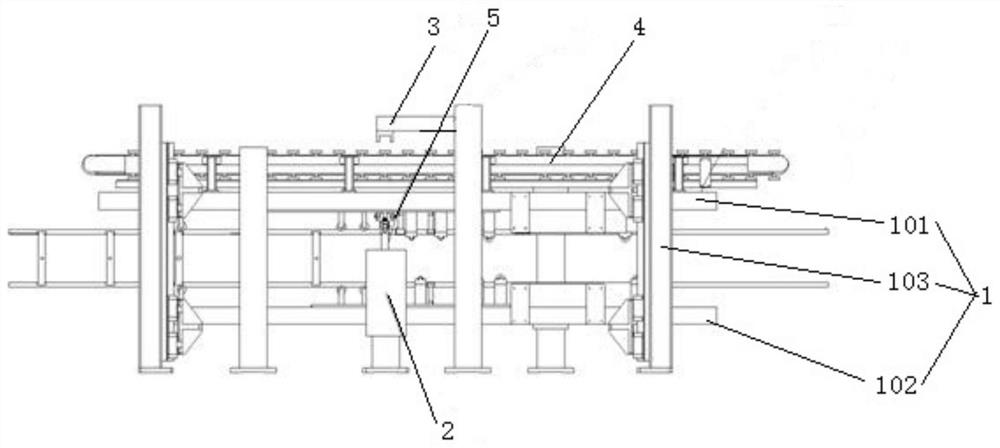

[0040] Such as figure 1 As shown, a main keel welding equipment provided by an embodiment of the present invention includes a frame 1 and a welding device 2 . The welding device 2 is used for welding the main keels, that is, welding the stiffening sheet between the two main keels, so that the two main keels are integrated. The welding device 2 is arranged opposite to the frame 1 . The welding device 2 can be connected with the frame 1, or can be set independently without being connected with the frame 1. When in use, the main keels to be welded are located in the frame 1 and arranged vertically. The vertical arrangement of main keels to be welded refers to the arrangement of two or more main keels up and down.

[0041] Using the main keel welding equipment of the above embodiment, the main keel is placed in the frame 1 . The main keel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com