Tombarthite powder grinding and processing equipment

A kind of processing equipment and rare earth technology, which is applied in the field of rare earth grinding and processing equipment, can solve the problems of high labor intensity, waste, and low efficiency of rare earth grinding, and achieve the effect of convenient grinding, improving grinding efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

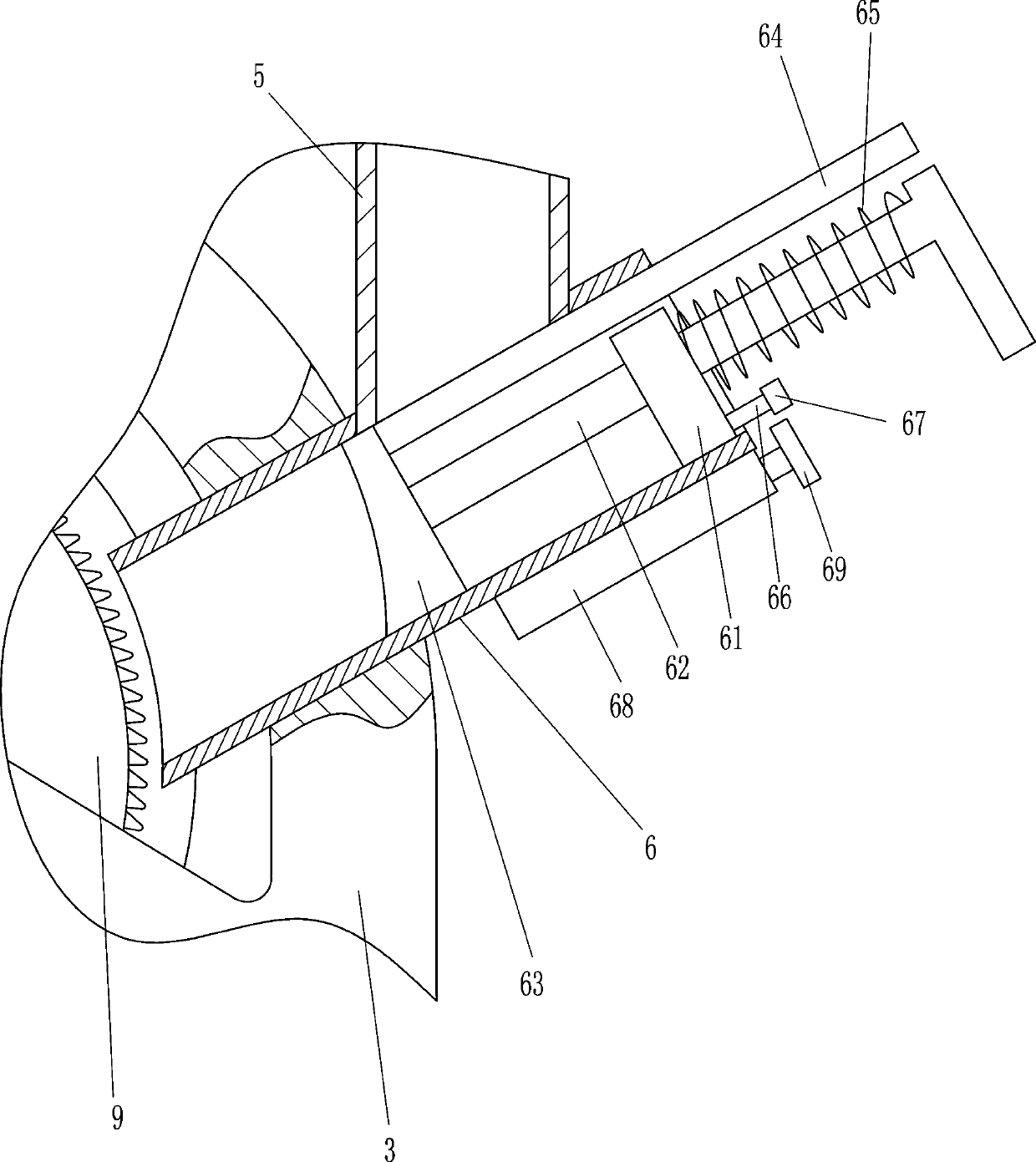

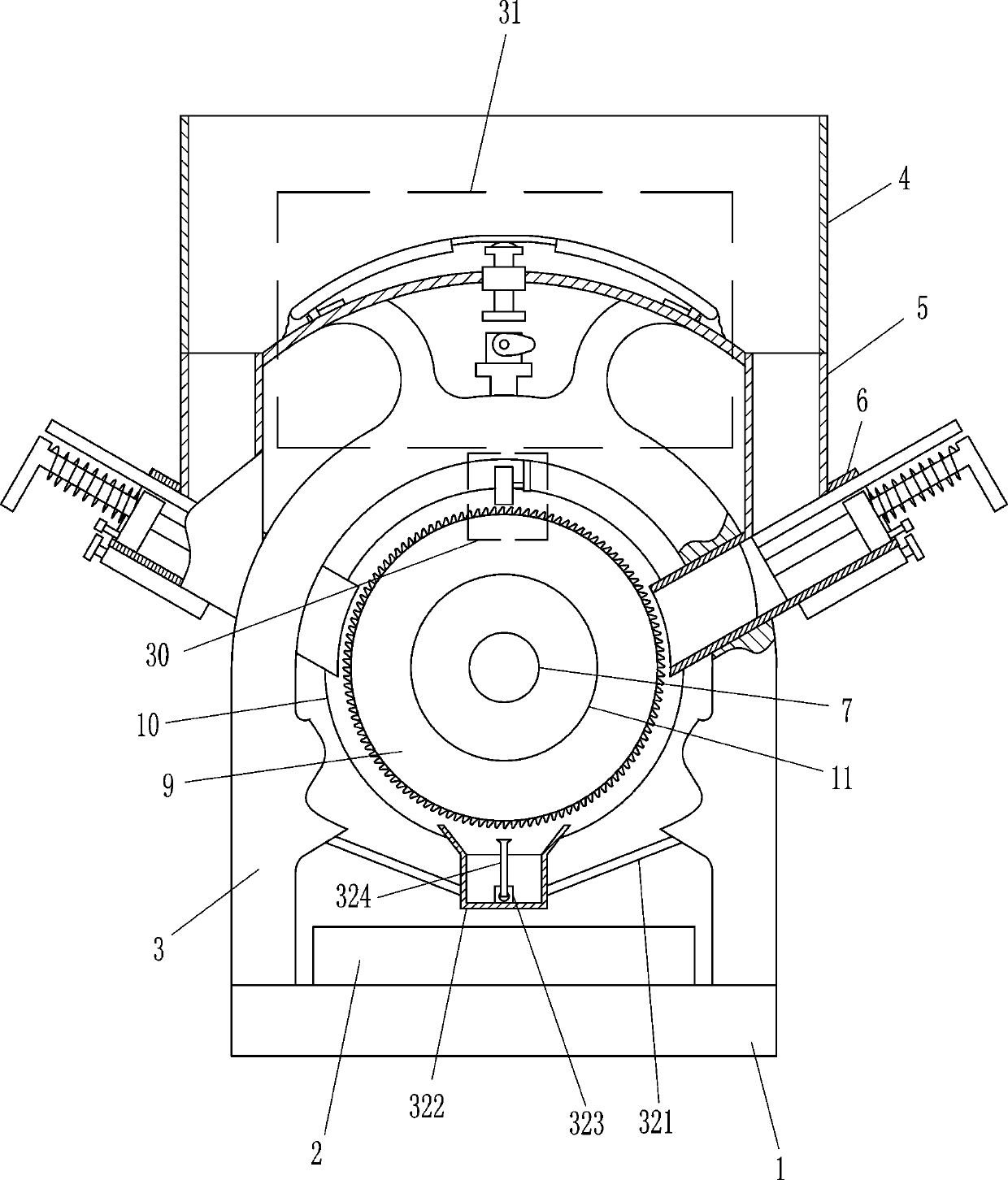

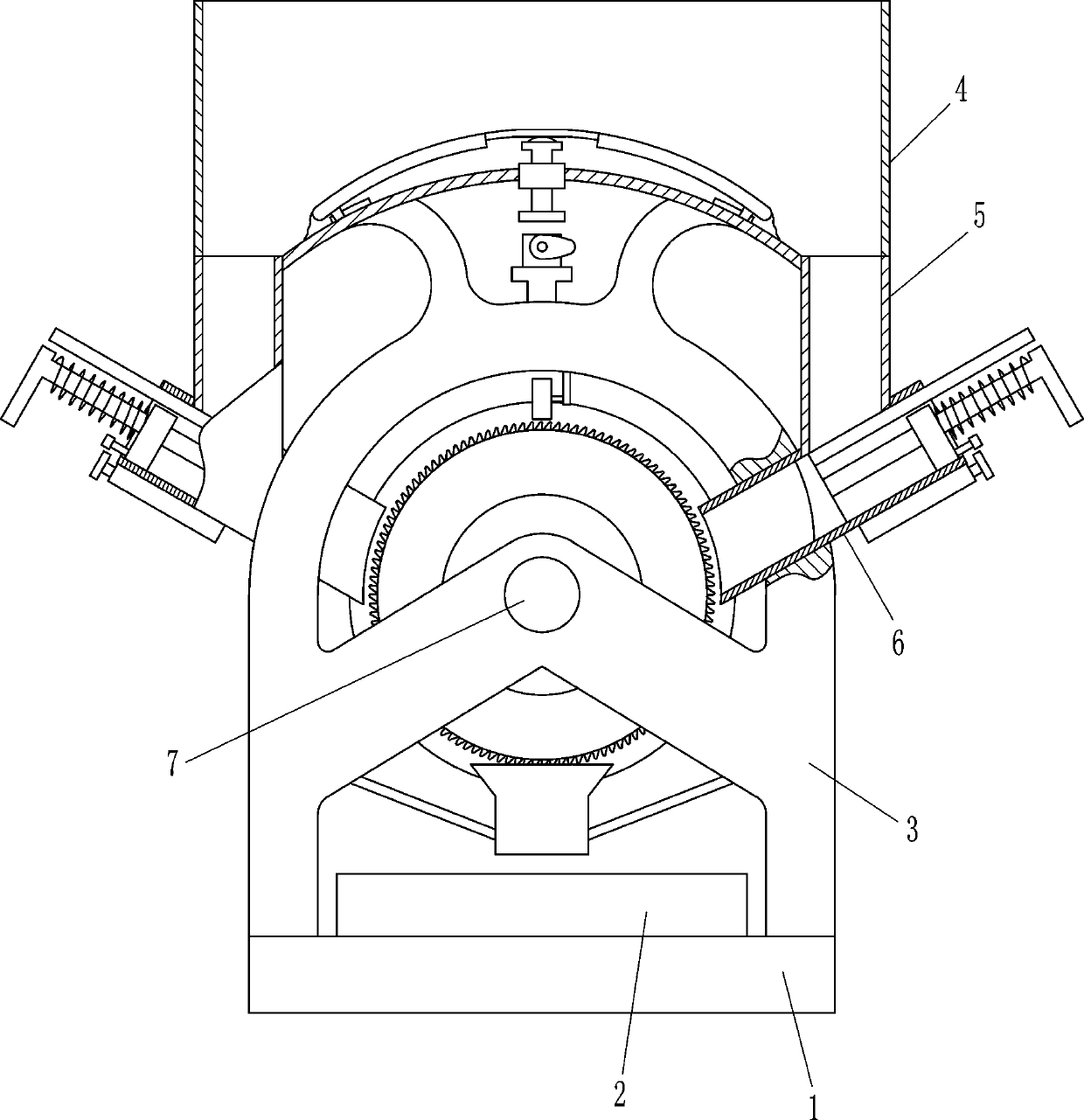

[0018] A kind of rare earth grinding processing equipment, such as Figure 1-4 As shown, it includes a bottom plate 1, a collection box 2, a mounting frame 3, a rare earth box 4, a feeding tube 5, a pushing tube 6, a first guide sleeve 61, a first guide rail 62, a pushing block 63, and a moving baffle 64 , spring 65, first extension block 66, contact switch 67, electric push rod 68, moving block 69, fixed rod 7, first bearing seat 8, grinding wheel 9, tapered stop disc 10, rotating ring 11, first gear 12 , drive motor 13 and second gear 14, collection box 2 is placed on the top of base plate 1, mounting frame 3 is arranged on the top of base plate 1, base plate 1 is connected with mounting frame 3 by the mode of bolt connection, and the top of mounting frame 3 is affixed There is a rare earth box 4 which plays a role in holding, and the installation frame 3 is connected with the rare earth box 4 by means of bolt connection. The left and right sides of the bottom of the rare ea...

Embodiment 2

[0020] A kind of rare earth grinding processing equipment, such as Figure 1-5As shown, it includes a bottom plate 1, a collection box 2, a mounting frame 3, a rare earth box 4, a feeding tube 5, a pushing tube 6, a first guide sleeve 61, a first guide rail 62, a pushing block 63, and a moving baffle 64 , spring 65, first extension block 66, contact switch 67, electric push rod 68, moving block 69, fixed rod 7, first bearing seat 8, grinding wheel 9, tapered stop disc 10, rotating ring 11, first gear 12 , drive motor 13 and second gear 14, the top of bottom plate 1 is placed with collecting box 2, and the top of bottom plate 1 is provided with mounting frame 3, and the top of mounting frame 3 is fixedly connected with the rare earth box 4 that plays a full-blown effect, rare earth box 4 The left and right sides of the bottom are equipped with feed tubes 5 that can transport rare earths, and the left and right sides of the installation frame 3 are equipped with push tubes 6. T...

Embodiment 3

[0023] A kind of rare earth grinding processing equipment, such as Figure 1-6 As shown, it includes a bottom plate 1, a collection box 2, a mounting frame 3, a rare earth box 4, a feeding tube 5, a pushing tube 6, a first guide sleeve 61, a first guide rail 62, a pushing block 63, and a moving baffle 64 , spring 65, first extension block 66, contact switch 67, electric push rod 68, moving block 69, fixed rod 7, first bearing seat 8, grinding wheel 9, tapered stop disc 10, rotating ring 11, first gear 12 , drive motor 13 and second gear 14, the top of bottom plate 1 is placed with collecting box 2, and the top of bottom plate 1 is provided with mounting frame 3, and the top of mounting frame 3 is fixedly connected with the rare earth box 4 that plays a full-blown effect, rare earth box 4 The left and right sides of the bottom are equipped with feed tubes 5 that can transport rare earths, and the left and right sides of the installation frame 3 are equipped with push tubes 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com