Structure of network-shaped lightweight metal zinc electrode and preparation method thereof

A lightweight, network-like technology, used in electrode manufacturing, structural parts, battery electrodes, etc., can solve the problems of reducing new metal negative electrodes, high cost, and difficult processing, and achieves improved cycle performance, increased energy density, and ease of use. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

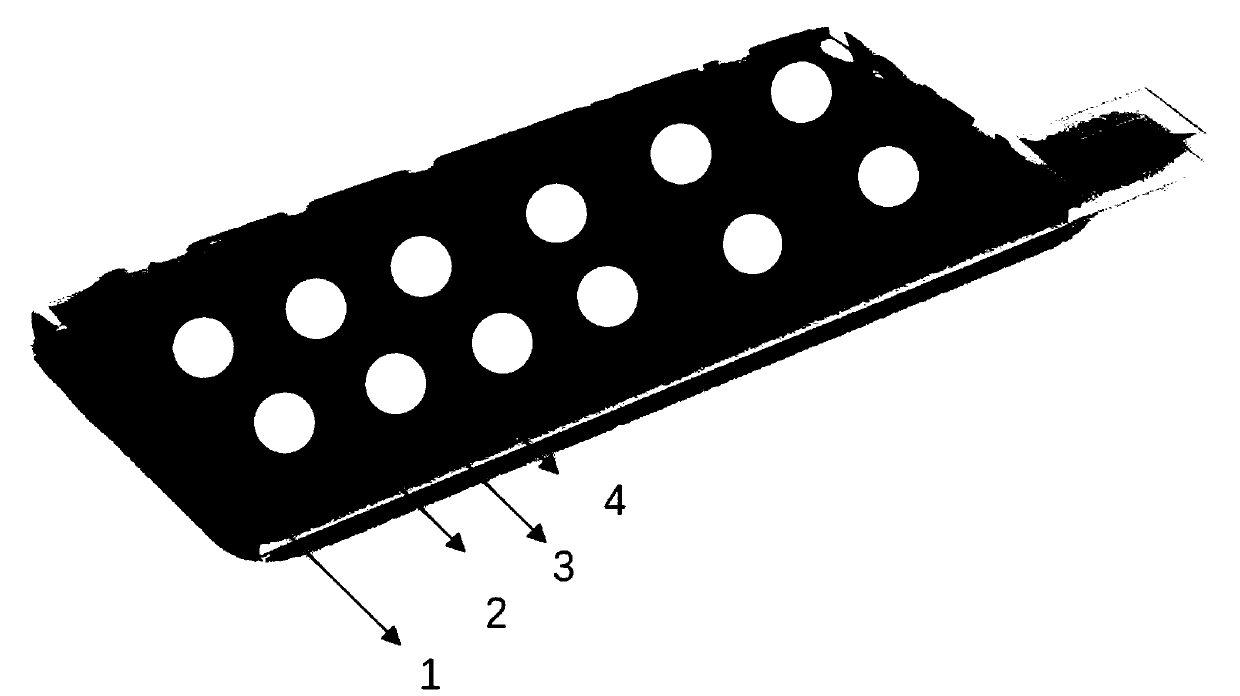

[0041] A 0.05 mg / μl polyvinylidene fluoride (PVDF) binder was prepared. Add polyvinylidene fluoride (PVDF) into methylpyrrolidone (NMP) solution and perform magnetic stirring for 10 hours to obtain a uniformly dispersed binder. Weigh zinc powder, carbon fiber, polyvinylidene fluoride (PVDF) binder and metal bismuth according to the mass percentage ratio of 70:25:4:1 and place them in a beaker, add a stirring magnet and place them on a magnetic stirrer Stir for 5h to obtain a homogeneous slurry.

[0042] The perforated zinc strip is pretreated to degrease, decontaminate and remove the oxide layer. The perforated zinc strip is polished with sandpaper, then ultrasonicated, rinsed with deionized water and alcohol three times, and then dried. The slurry was coated on a punched zinc strip with a thickness of 200 μm, and dried in an oven at 70°C to obtain a lightweight metal zinc electrode.

[0043] The full battery is assembled with manganese oxide as the positive electrode, glass f...

Embodiment 2

[0049] A 0.05 mg / μl polyvinylidene fluoride (PVDF) binder was prepared. Add polyvinylidene fluoride (PVDF) into methylpyrrolidone (NMP) solution and perform magnetic stirring for 10 hours to obtain a uniformly dispersed binder. Weigh zinc powder, graphite, polyvinylidene fluoride (PVDF) binder and metal bismuth according to the mass percentage ratio of 70:25:4:1, put them in a beaker, add a stirring magnet and place them on a magnetic stirrer Stir for 5h to obtain a homogeneous slurry.

[0050] The perforated zinc strip is pretreated to degrease, decontaminate and remove the oxide layer. The perforated zinc strip is polished with sandpaper, then ultrasonicated, rinsed with deionized water and alcohol three times, and then dried. The slurry was coated on a punched zinc strip with a thickness of 200 μm, and dried in an oven at 70°C to obtain a lightweight metal zinc electrode.

[0051] The full battery is assembled with manganese oxide as the positive electrode, glass fiber as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com