Fuzzy fault diagnosis and prediction representation method based on size characteristic similarity measurement

A similarity measurement and fault diagnosis technology, which is applied in character and pattern recognition, image data processing, instruments, etc., can solve the problems of no uniform standard for fault diagnosis, difficulty in realizing real-time judgment, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

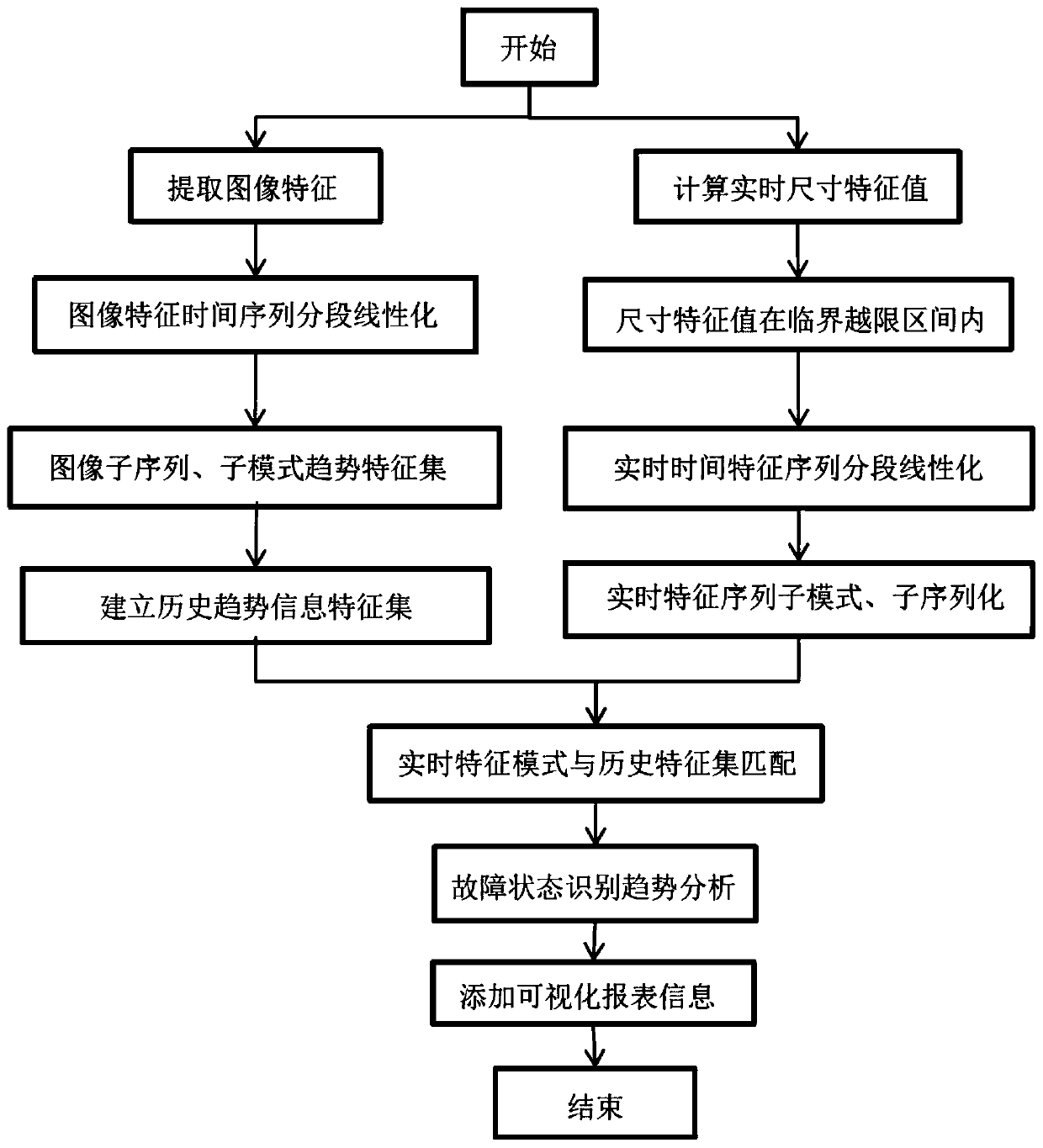

[0054] figure 1 It is a flowchart of the present invention.

[0055] Step 1: Use the flotation on-site image acquisition system to collect the froth video of zinc flotation at historical moments and convert the froth video into continuous images, and perform data preprocessing on the collected zinc flotation image data, as follows:

[0056] 1) Eliminate erroneous data that exceeds the normal change threshold;

[0057] 2) Eliminate incomplete data;

[0058] Step 2: Convert the foam image from an RGB color image to a grayscale image, and use the watershed algorithm to segment the image, extract the mean value of the size as the source image feature, and obtain a time series image feature I=[I 1 ,I 2 ,...,I q ], q is the number of image features arranged in chronological order;

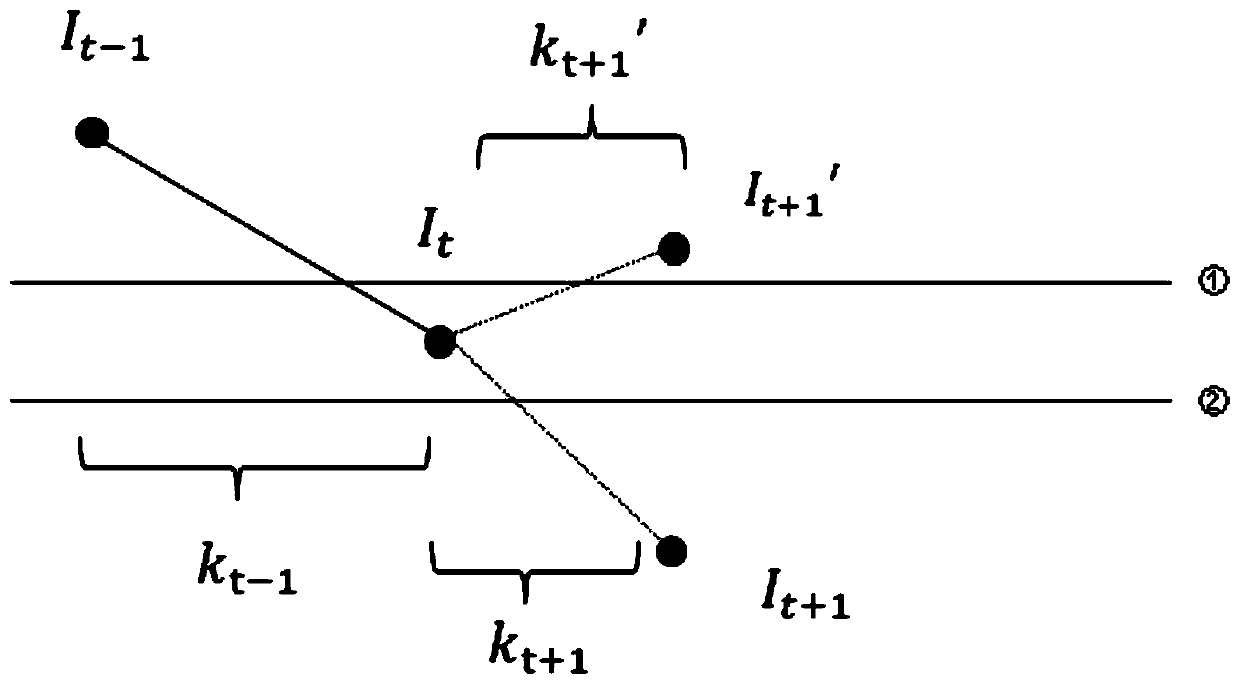

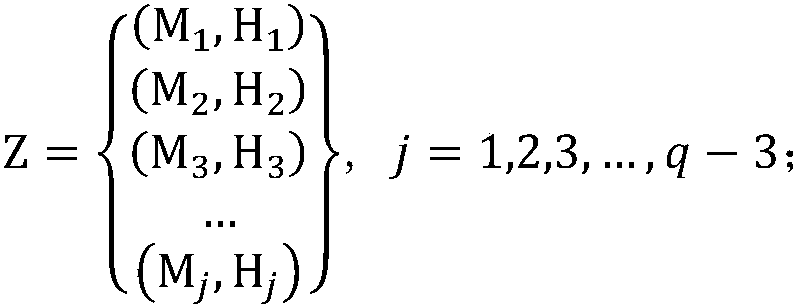

[0059] Step 3: Use the piecewise linearization algorithm for the image feature I of the time series, take all extreme points as endpoints, perform piecewise linearization on the time series, and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com