Solar assisted heat pump drying system

A heat pump drying and heat pump system technology, applied in the drying field, can solve problems such as unreasonable structure and low energy utilization rate, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

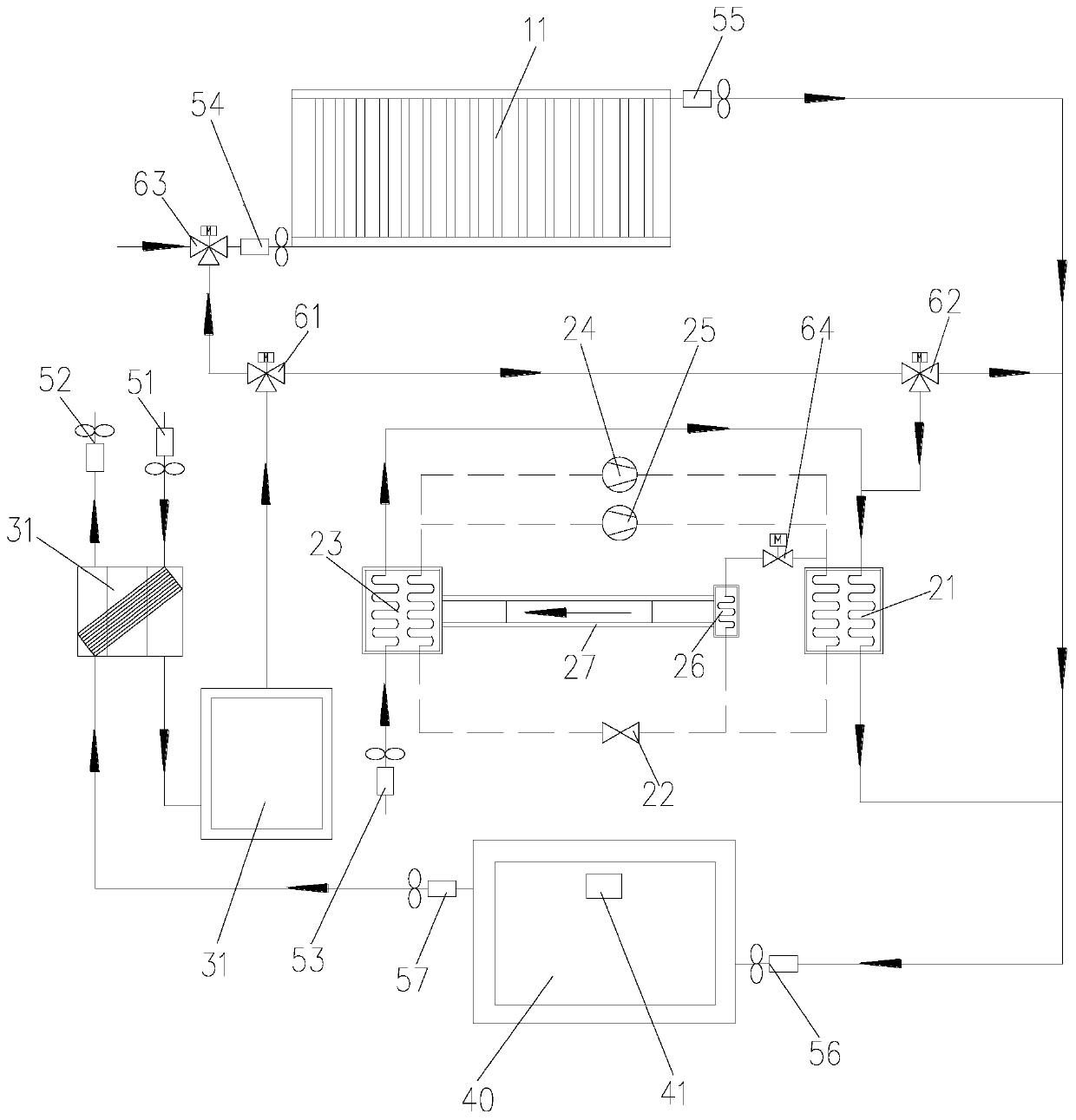

[0047] A kind of solar energy auxiliary heat pump drying system is provided in this embodiment, such as figure 1 As shown, the solar assisted heat pump drying system includes a drying chamber 41, a two-stage compression heat pump system and a solar vacuum heat pipe heat collection system, and the two-stage compression heat pump system is connected to the drying chamber 41 and used to dry the air through a drying medium. The chamber 41 provides the heat energy required for drying, and the solar vacuum heat pipe heat collection system is connected with the drying chamber 41 and is used to provide the heat energy required for drying to the drying chamber 41 through the drying medium. The solar vacuum heat pipe heat collection system is connected with the drying chamber 41. a two-stage compression heat pump system connected and used to preheat the drying medium entering said two-stage compression heat pump system;

[0048] The drying chamber 41 is a closed drying space for the art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com