Novel high-speed and high-precision all-ceramic roller bearing

A roller bearing, high-precision technology, applied in the field of bearings, can solve problems such as inseparable from high-speed ultra-precision bearings, large amount of thermal deformation of metal bearings, and unusable metal bearings, etc., to achieve light weight, small thermal expansion coefficient, and reduce The effect of energy expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

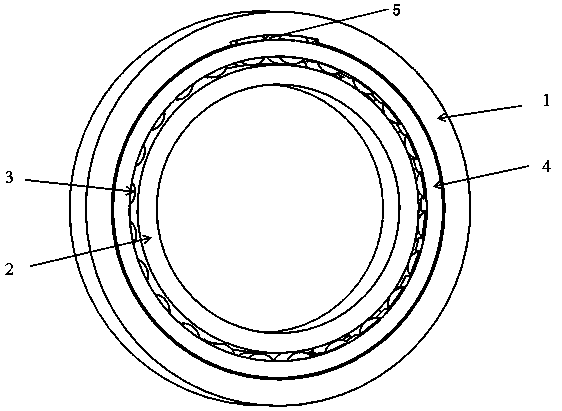

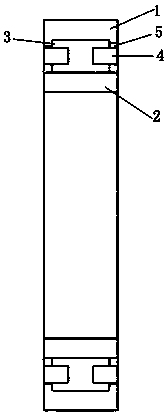

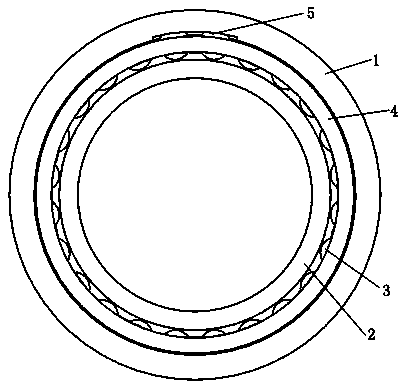

[0019] Example: such as figure 1 and figure 2 As shown, a new type of high-speed high-precision roller bearing, including the outer ring 1 (such as Figure 5 shown), inner ring 2 (as Figure 6 shown), roller 3 (as Figure 8 shown), cage 4 (as Figure 7 As shown), the roller 3 is between the inner ring 2 and the outer ring 1, and the cage 4 is around the roller 3 to restrain the axial shaking of the roller 3 and space the rollers 3 from each other to avoid mutual interference. Friction; while guiding the roller 3 to rotate around the common center point of the inner ring 2 and the outer ring 1. The inner ring 2 is installed on the shaft, and the outer ring 1 is installed in the bearing seat.

[0020] Due to the high hardness and small expansion coefficient of ceramic materials, non-destructive installation is relatively difficult. In order to achieve non-destructive installation, a groove 5 with an arc of 30 degrees is opened on the shoulder of the outer ring 1 side. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com