Preparation method of high-stability adefovir dipivoxil

An adefovir dipivoxil, high-stability technology, applied in the field of drug synthesis, can solve the problems of thermal instability, poor stability and small particle size of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

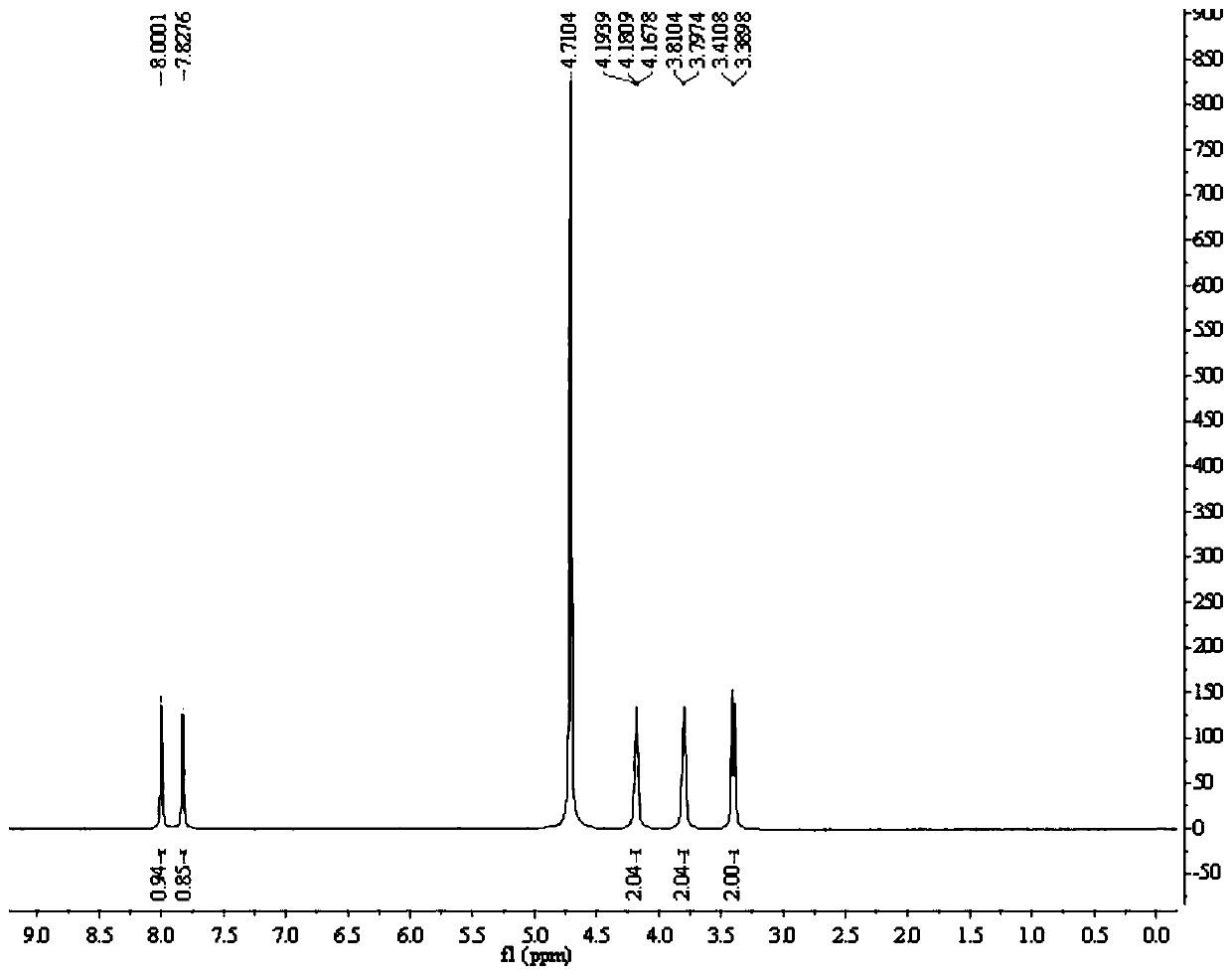

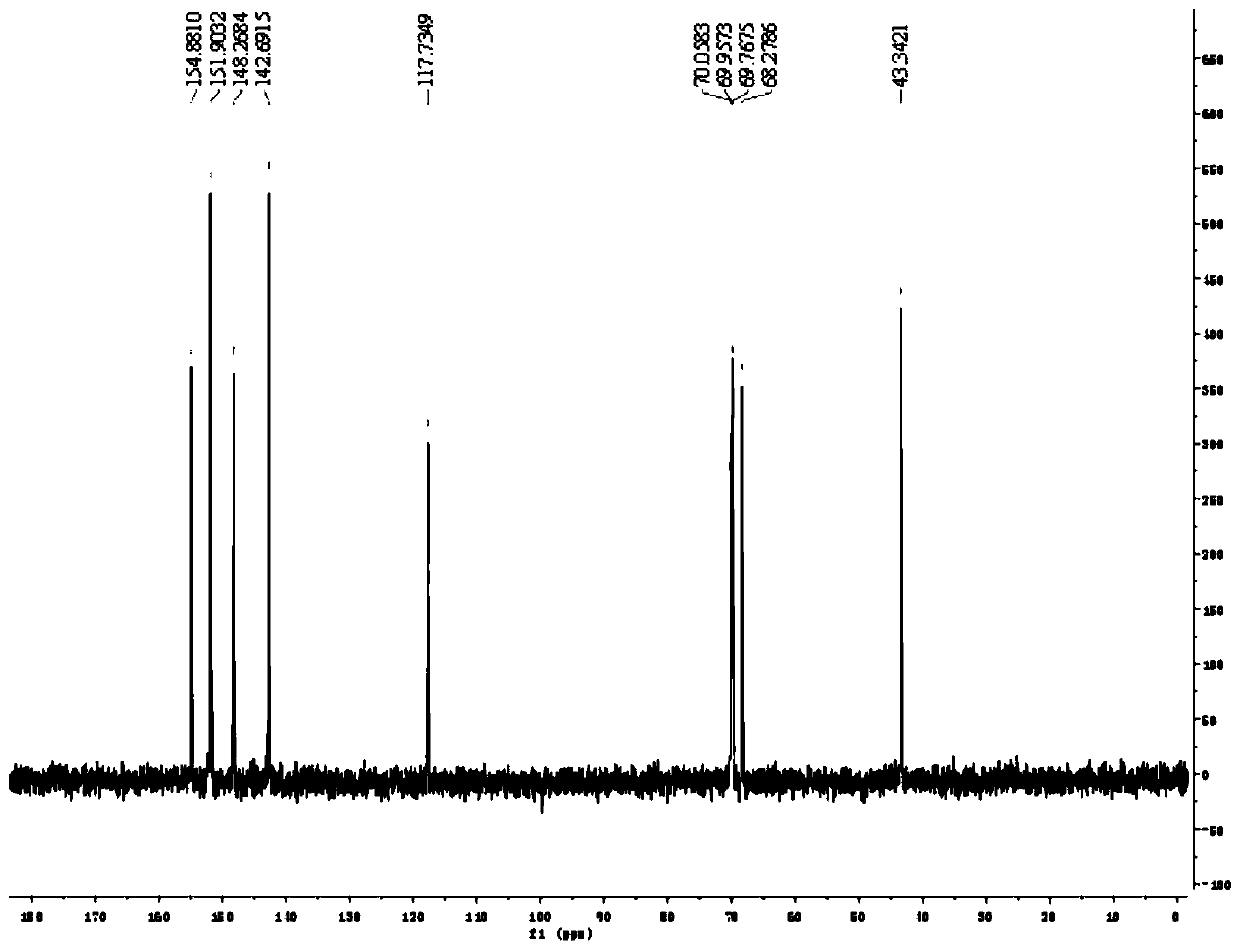

Image

Examples

Embodiment 1

[0052] Add 5.20kg (2w / w) of acetonitrile into a 50L reactor, add 2.60kg (1eq) of compound 1 and 4.24kg (3.5eq) of bromotrimethylsilane under stirring, raise the temperature to 65±5°C, and keep the reaction for 2 hours. Concentrate the organic phase under reduced pressure at 45±5°C until no liquid distills out, add 7.80kg (3w / w) of purified water to dissolve the organic phase, raise the temperature to 55±5°C and stir for 0.5 hours; add 30% NaOH aqueous solution dropwise to the 50L reaction kettle Adjust the pH to 2.5-3.5, raise the temperature to 75±5°C and keep stirring for 2 hours; cool down to 3±3°C and keep stirring for 3 hours; centrifuge, and filter the cake with 2.60kg (1w / w) of purified water and 1.30kg of ethanol (0.5 w / w) washing; add 10.40kg (4w / w) of purified water to the 50L reactor, add filter cake under stirring, heat up to 75±5°C, beat for 2 hours; cool down to 3±3°C for 3 hours; centrifuge , the filter cake was washed with 2.60kg (1w / w) of purified water; the f...

Embodiment 2

[0058] Add 5.20kg (2w / w) of DMF to the 50L reactor, add 2.60kg (1eq) of compound 1 and 1.72kg (2eq) of trimethylchlorosilane under stirring, raise the temperature to 55±5°C, and keep the reaction for 2 hours. Concentrate the organic phase under reduced pressure at 45±5°C until no liquid distills out, add 7.80kg (3w / w) of purified water to dissolve the organic phase, raise the temperature to 55±5°C and stir for 0.5 hours; add 30% NaOH aqueous solution dropwise to the 50L reaction kettle Adjust the pH to 2.5-3.5, raise the temperature to 75±5°C and keep stirring for 2 hours; cool down to 3±3°C and keep stirring for 3 hours; centrifuge, and filter the cake with 2.60kg (1w / w) of purified water and 1.30kg of ethanol (0.5 w / w) washing; add 10.40kg (4w / w) of purified water to the 50L reactor, add filter cake under stirring, heat up to 75±5°C, beat for 2 hours; cool down to 3±3°C for 3 hours; centrifuge , the filter cake was washed with 2.60kg (1w / w) of purified water; the filter cake...

Embodiment 3

[0064] Add 5.20kg (2w / w) of tetrahydrofuran into a 50L reactor, add 2.60kg (1eq) of compound 1 and 7.92kg (5eq) of iodotrimethylsilane under stirring, raise the temperature to 75±5°C, and keep the reaction for 2 hours. Concentrate the organic phase under reduced pressure at 45±5°C until no liquid distills out, add 7.80kg (3w / w) of purified water to dissolve the organic phase, raise the temperature to 55±5°C and stir for 0.5 hours; add 30% NaOH aqueous solution dropwise to the 50L reaction kettle Adjust the pH to 2.5-3.5, raise the temperature to 75±5°C and keep stirring for 2 hours; cool down to 3±3°C and keep stirring for 3 hours; centrifuge, and filter the cake with 2.60kg (1w / w) of purified water and 1.30kg of ethanol (0.5 w / w) washing; add 10.40kg (4w / w) of purified water to the 50L reactor, add filter cake under stirring, heat up to 75±5°C, beat for 2 hours; cool down to 3±3°C for 3 hours; centrifuge , the filter cake was washed with 2.60kg (1w / w) of purified water; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com