Facility for extracting dihydroartemisinic acid from waste oil generated in artemisinin production

A technology of dihydroartemisinic acid and artemisinin, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of unfavorable industrial production of dihydroartemisinic acid, complex process routes, and low product quality. Achieve the effects of easy industrialization and promotion, good filtering effect and short filtering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

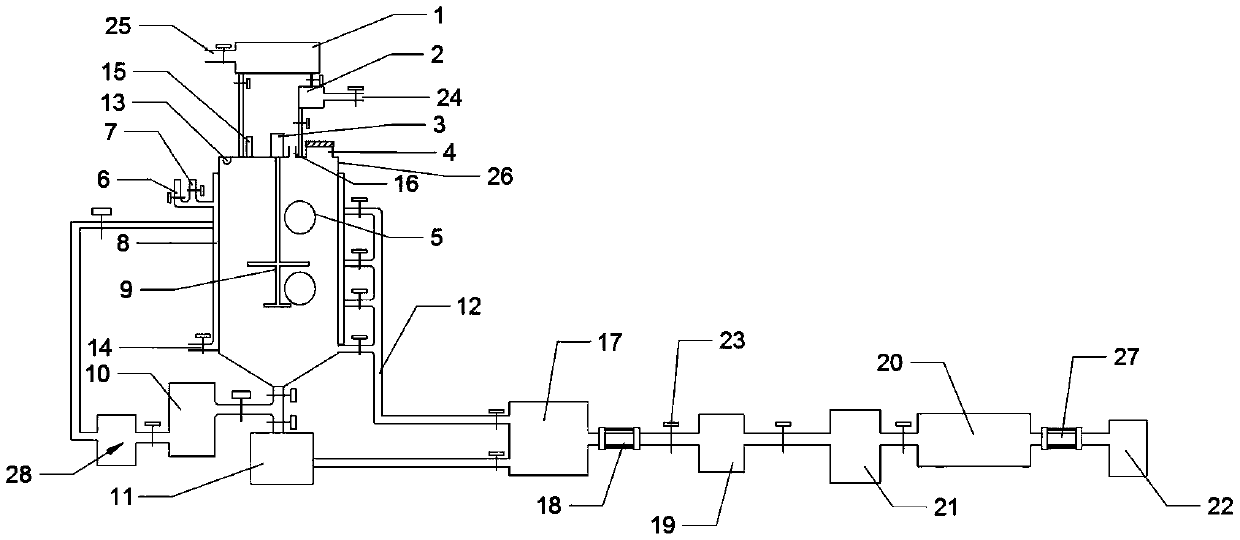

[0026] Take 100KG of artemisinin production waste oil containing 6.5% dihydroartemisinic acid and pour it into the feeding port 4, turn on the stirring motor 3, and add the extraction solution containing alkaline substances from the liquid inlet 16 under the stirring rod 9 , the alkaline substance is one of sodium hydroxide, sodium bicarbonate, disodium bicarbonate, and potassium hydroxide, and the extraction solvent is one of water, methanol water, ethanol water, and acetone water, and the concentration is 20- 80%, the present embodiment adopts 2000L of 50% methanol aqueous solution containing 10% sodium hydroxide; after mixing, keep stirring at room temperature for 8 hours, turn off the stirring motor and let it stand for 4 hours; the obtained extract has obvious stratification, and the upper layer is about 1400L; Open the valve at the corresponding position of the supernatant discharge pipe 12 according to the liquid level of the supernatant, use the vacuum storage tank 19 t...

Embodiment 2

[0028]Take 10 kilograms of dihydroartemisinic acid crude product fluid paste with a content of about 30% and pour it from the feeding port 4, add 1000 ml of acetone solvent with a volume fraction of 30% from the liquid inlet 16, turn on the stirring motor 3 and stir for 30 minutes, then statically Place crystallization in 48 hours; open the valve after the crystallization is complete, control the crystallization liquid to flow into the three-legged centrifuge 11 and carry out filtration and centrifugation, open the valve of the liquid storage tank 10 and the feed liquid pump 23, and make the primary crystallization mother liquid return in the extraction tank 26 and carry out Repeat the extraction, repeat the above steps 4 times, and combine to obtain 3.65 kg of off-white crystals, the content of dihydroartemisinic acid is 78% after testing; pour 3.65 kg of off-white crystals from the feeding port 4, and add the concentration from the liquid inlet 16 It is 36.5L of 50% acetone s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com