Array type dry ice spray head and gas-solid mixture generation method

An array-type, spray-head technology, applied in chemical instruments and methods, cleaning methods and utensils, spray devices, etc., can solve the problems of invariable spray direction and flow rate, single method of spray production, poor gas mixing effect, etc. Simple, small size, uniform air mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

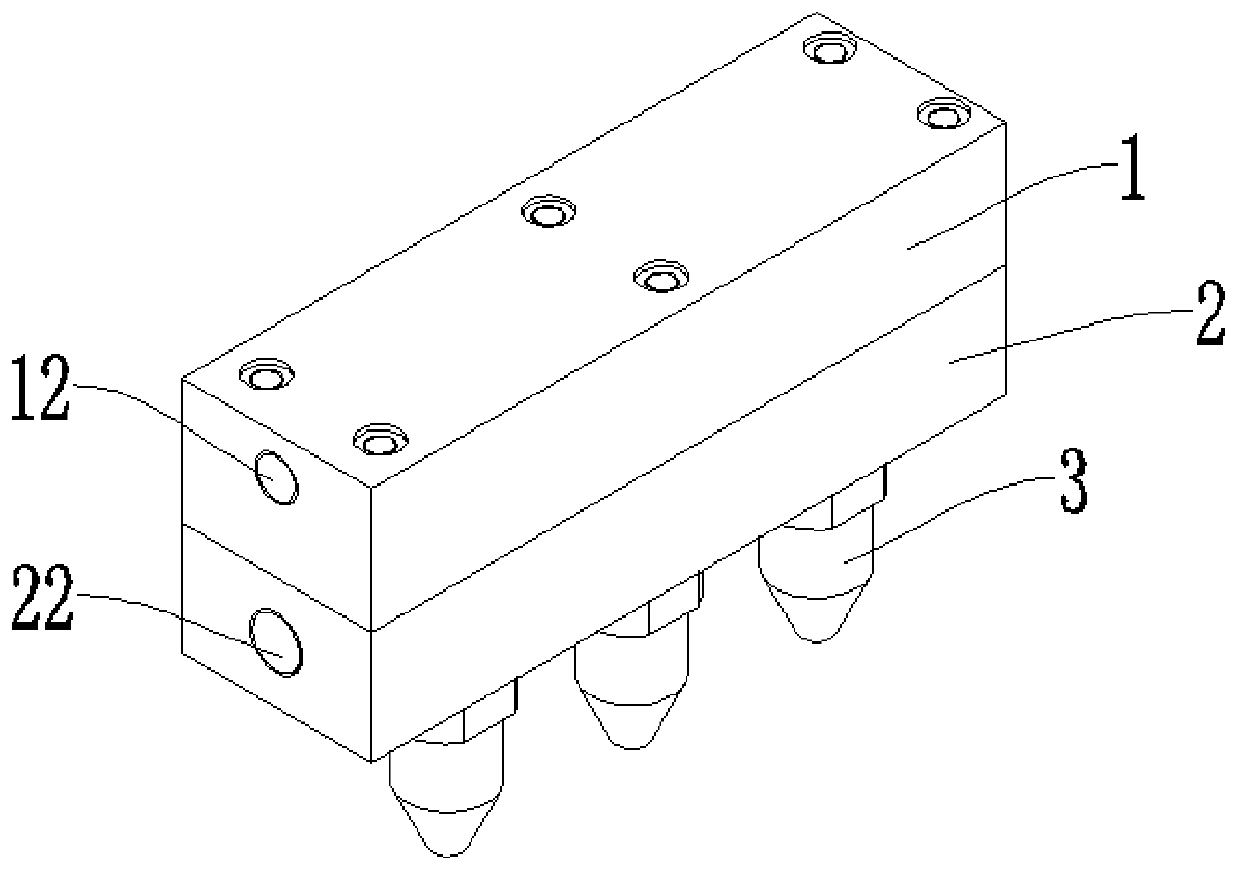

[0048] refer to figure 1 As shown, the first embodiment of the present invention provides an array type dry ice spray head, including an upper cavity 1, a lower cavity 2, and a plurality of spray head assemblies 3 socketed in the upper cavity 1 and the lower cavity 2 . The structure is simple, modular, small in size, and can be used in combination. It can also be connected to an external fully automatic manipulator to control the cleaning path of the device through programming. It can be applied to complex working environments with high quality requirements.

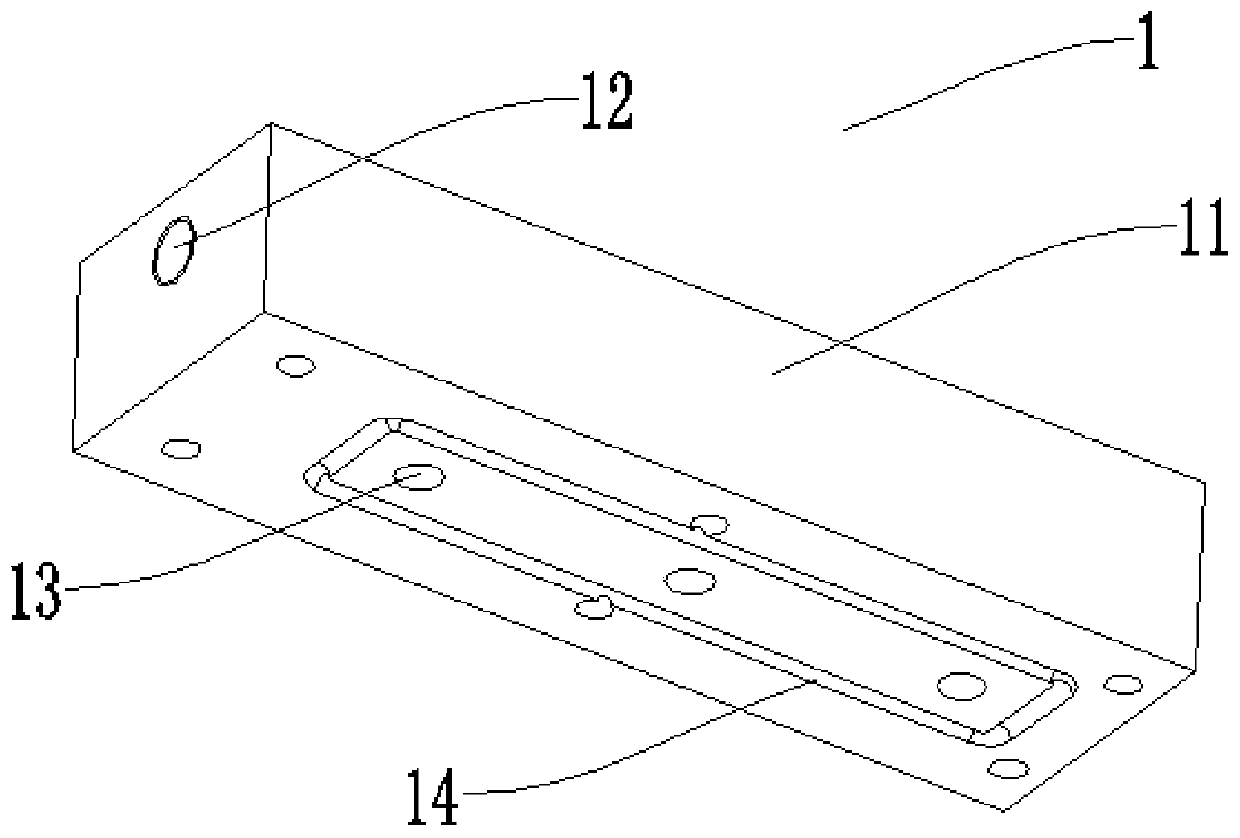

[0049] refer to Figure 1-6 As shown, in this embodiment, the upper chamber body 1 includes an upper chamber frame 11, a liquid inlet pipe 12 pierced through the upper chamber frame 11, and a plurality of pipes vertically arranged on the body of the liquid inlet pipe 12. The first branch pipe 13 . The lower cavity body 2 is fixedly connected to the upper cavity body 1, and includes a lower cavity frame 21, an air inta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com