Wound repair material for cell suspension transplantation and preparation method of wound repair material

A technology of wound repair and cell suspension, applied in medical science, prosthesis, etc., can solve the problems affecting the speed and quality of wound healing, high fluidity of transplantation, shedding of epidermal cells, etc., to reduce the formation of granulation tissue and optimize Pore structure, effect of reducing wound contracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

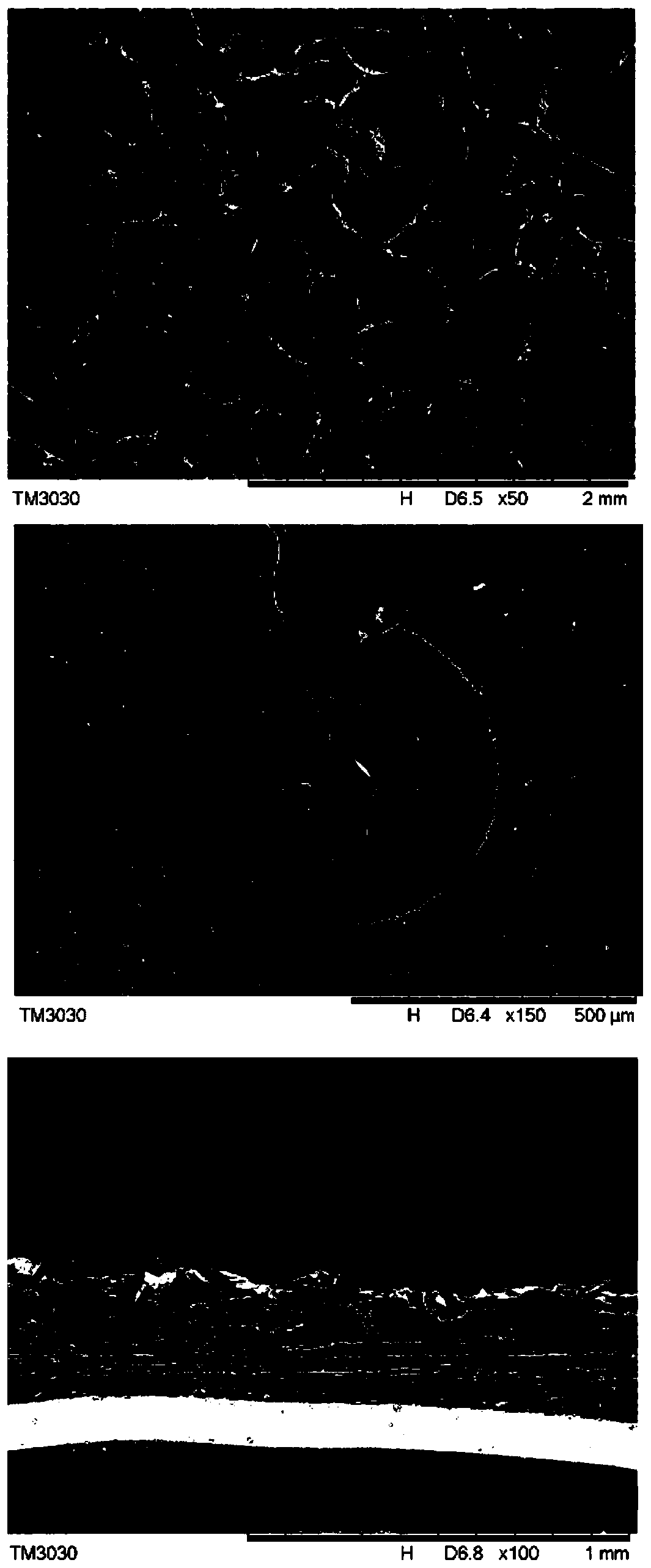

[0034] This embodiment provides a wound repair material, which is prepared according to the following steps: dissolving type I collagen in water, and preparing 50 g of an aqueous collagen solution with a pH of 4.68 and a mass fraction of 0.35 wt%. 4.86mL, 3.6mg / mL chondroitin sulfate aqueous solution was slowly added dropwise to the above collagen aqueous solution to obtain a collagen-based composite solution with a mass-to-feed ratio of 10:1, wherein the amount of chondroitin sulfate added was 9.09wt%. After aliquoting the above collagen-based complex solution, freeze and centrifuge at 4°C and 8000 rpm for 10 min to obtain a translucent gel-like precipitate, which was diluted to 25.5 g with the supernatant. The diluted gel-like precipitate was transferred to an aluminum mold and smoothed, pre-cooled in a -60°C ultra-low temperature refrigerator, and then transferred to a -50°C lyophilizer for 18 hours of freeze-drying. After taking it out, transfer it to a vacuum drying oven ...

Embodiment 2

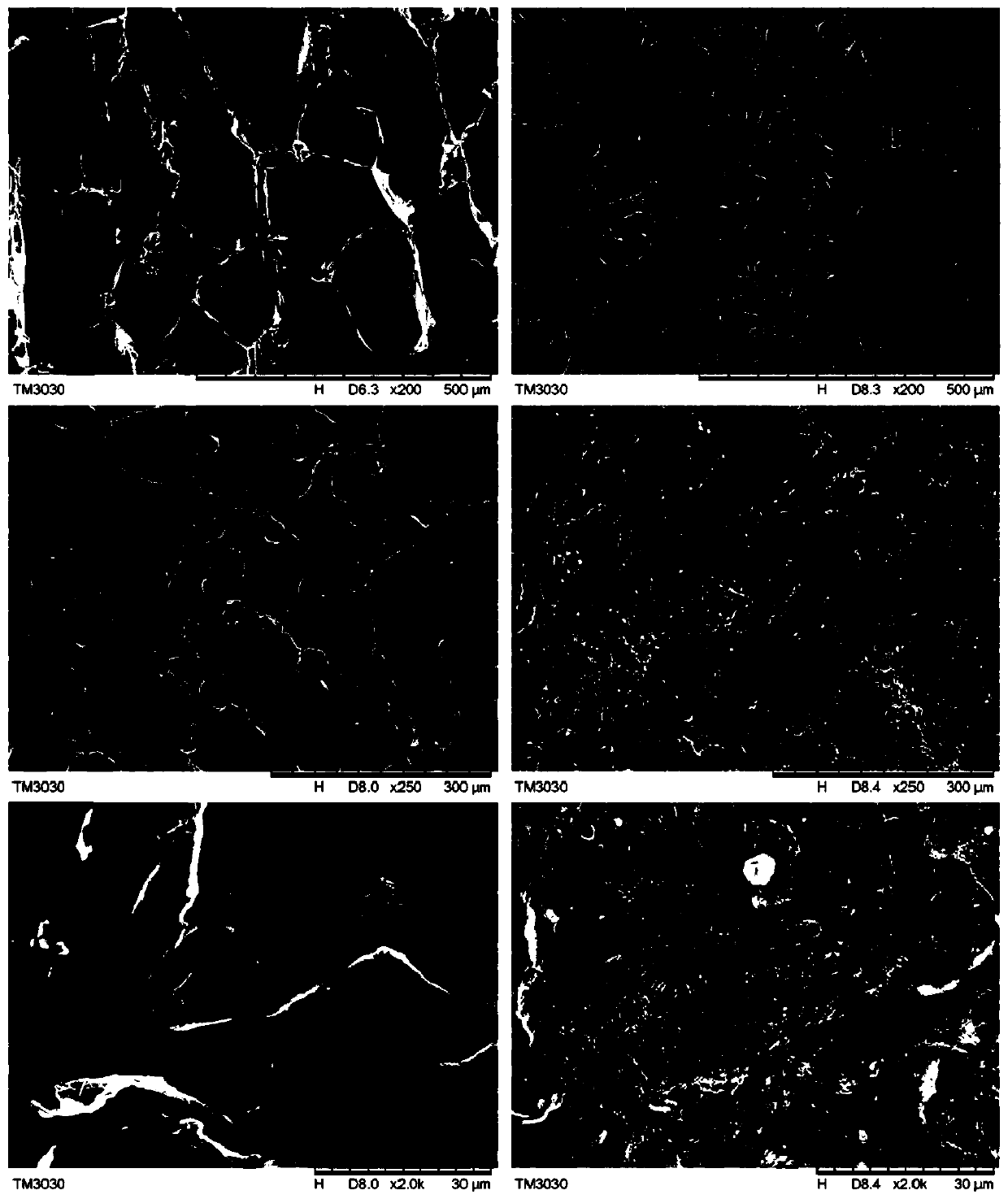

[0041] This embodiment provides a wound repair material, which is prepared according to the following steps: take type I collagen and dissolve it in water to prepare 50 g of an aqueous collagen solution with a pH of 3.2 and a mass fraction of 0.55 wt%. The α-elastin hydrolyzate was slowly added dropwise into the above aqueous collagen solution to obtain a collagen-based composite solution, wherein the added amount of α-elastin was 8 wt%. The above-mentioned collagen-based composite solution was transferred to an aluminum mold, scraped flat, pre-cooled in a -60°C ultra-low temperature refrigerator, and then transferred to a -50°C freeze dryer for 18 hours of freeze-drying. After taking it out, transfer it to a vacuum drying oven with a vacuum degree of -0.1MPa and a temperature of 105°C, and perform dehydration thermal crosslinking treatment for 24 hours to obtain a thickness of 2mm and an area density of 1.95mg / cm 2 , Collagen sponge with a porosity of 98%.

[0042] Using CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com