Design method of free-form surface wavefront compensation element for laser system

A laser system and compensating component technology, applied in optical components, optics, instruments, etc., can solve problems such as inability to effectively correct high-frequency noise, inability to characterize the surface shape of complex components, and limited travel of deformable mirrors, so as to correct system aberrations, The effect of simplified structure and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing, but protection scope of the present invention should not be limited

[0027] A design method for a free-form surface wavefront compensation element used in a laser system, comprising the following steps:

[0028] Step 1) Detect the distorted wavefront output by the laser system through the distorted wavefront detector, and measure the discrete data slope (S x ,S y ) to a computer;

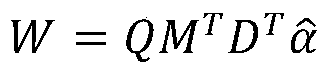

[0029] Step 2) Calculate and obtain the polynomial W representing the distortion wavefront;

[0030] Step 3) Let the free-form surface wavefront compensation element surface shape characterization polynomial W* required to compensate the distorted wavefront of the laser system satisfy the following relationship:

[0031] Such as figure 2 As shown, when the transmission system: satisfy W=-W*;

[0032] When the reflection system: for direct radiation, satisfy W=2W*, for oblique incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com