Method for determining escape ammonia in flue gas of cement plant

A cement plant and ammonia escape technology, applied in the field of measuring ammonia escape in cement plant flue gas, can solve the problems of ammonia escape, short practice, immature use technology for measuring ammonia escape, etc., and achieve the effect of obvious practicability and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

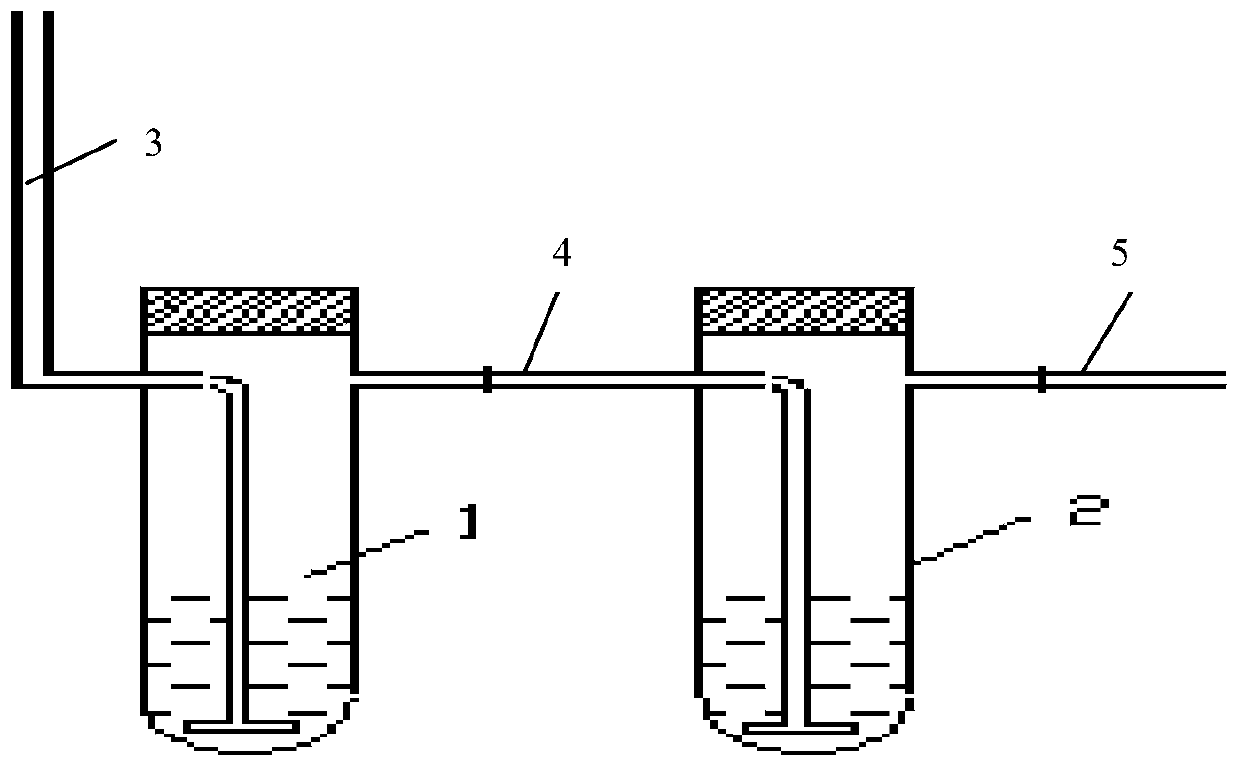

[0040]Before the experiment, wash and quickly dry the glass instruments such as colorimetric tubes and pipettes used. Use a sampling pump to control the flow of flue gas through the flue gas collection pipe to 5L / min, and the gas sampling time is 3.6min. The flue gas from the cement plant is fully absorbed by the sulfuric acid solution (absorbing solution) with a concentration of 0.005mol / L. The volume of sulfuric acid in each absorbing bottle is 30mL. After absorption, combine the absorbing solutions in the two absorbing bottles and dilute to 100mL with water. .

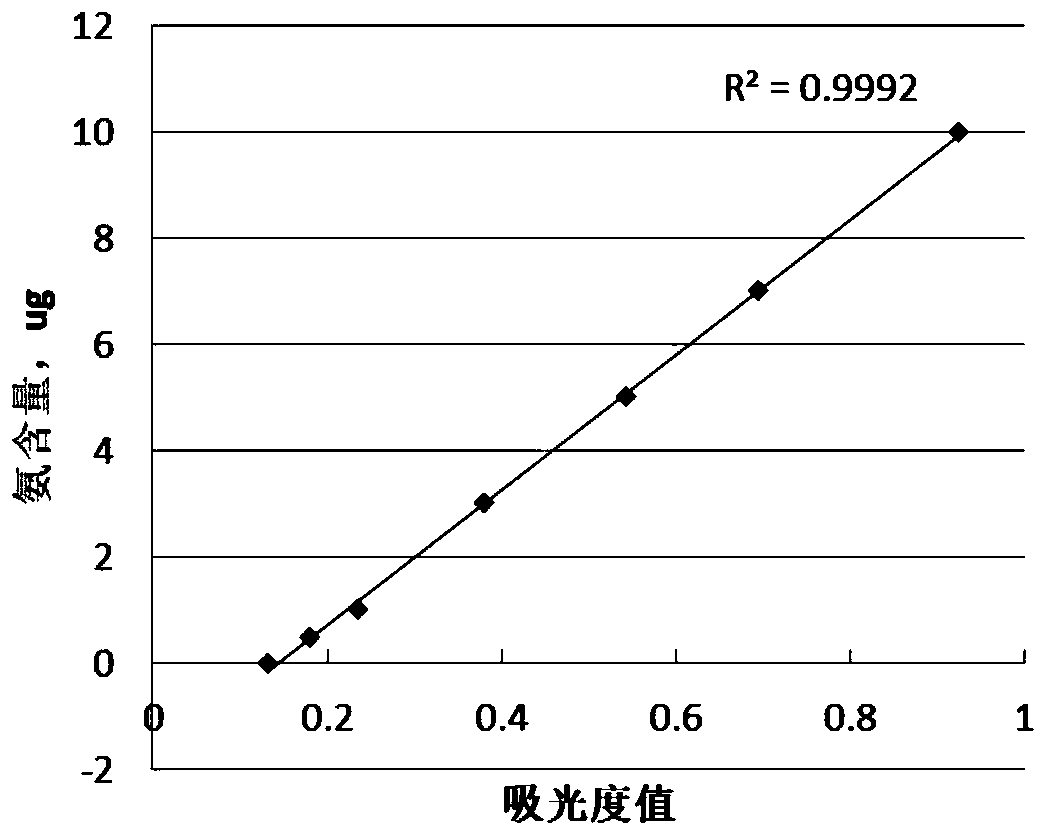

[0041] Prepare the standard curve solution: the concentration of the standard curve solution is 1 μg ammonia / mL, which is prepared by adding water to ammonium chloride.

[0042] Place 0-10ml of the standard curve solution and 1ml of the absorption solution after absorbing smoke into different 10mL stoppered colorimetric tubes. Dilute each colorimetric tube with water to the 10mL mark, add 0.5mL salicylic acid-tris...

Embodiment 2

[0044] Before the experiment, wash and quickly dry the glass instruments such as colorimetric tubes and pipettes used. Use a sampling pump to control the flow of flue gas through the flue gas collection pipe to 5L / min, and the gas sampling time to 1min. The cement factory flue gas is fully absorbed by the sulfuric acid solution with a concentration of 0.005mol / L. The volume of sulfuric acid in each absorption bottle is 50mL. After absorption, combine the absorption solutions in the two absorption bottles and dilute to 100mL with water.

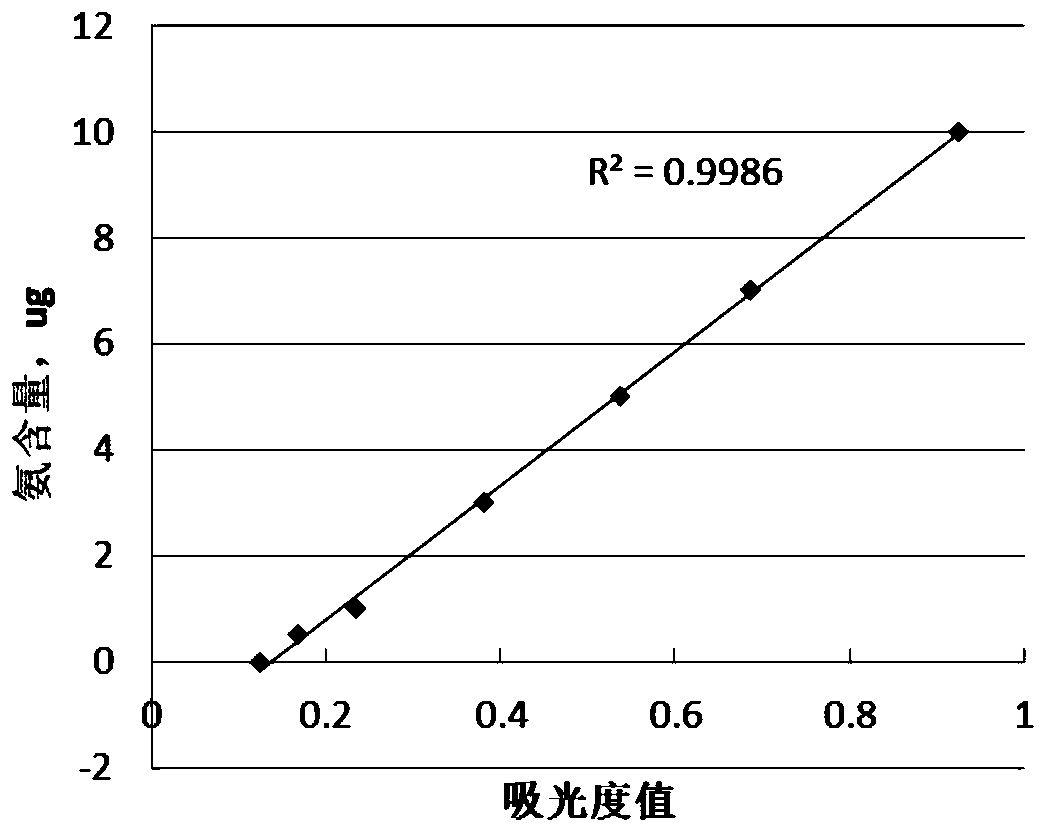

[0045] Prepare the standard curve solution: the concentration of the standard curve solution is 1 μg ammonia / mL, which is prepared by adding water to ammonium chloride.

[0046] Place 0-10ml of the standard curve solution and 5.5ml of the absorption solution after absorbing smoke into different 10mL stoppered colorimetric tubes. Dilute each colorimetric tube with water to the 10mL mark, add 0.5mL salicylic acid-trisodium citrate solution, 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com