A new type of bridge reinforcement system and its construction method

A bridge and system technology, applied in the new bridge reinforcement system and its construction field, can solve the problems of inability to adjust the eccentricity of prestressed steel bundles, inability to adjust the external prestressing effect, external bundle tension, repair or replacement, etc., to avoid construction. Problems and durability issues, the effect of simplified anchoring devices and simplified construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

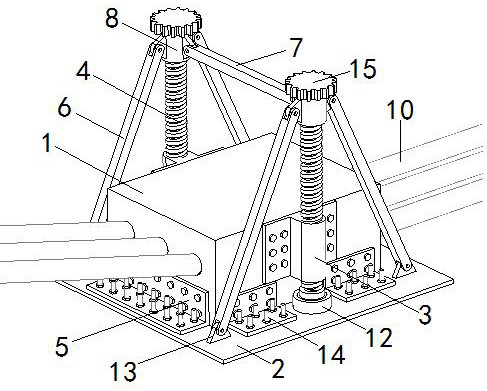

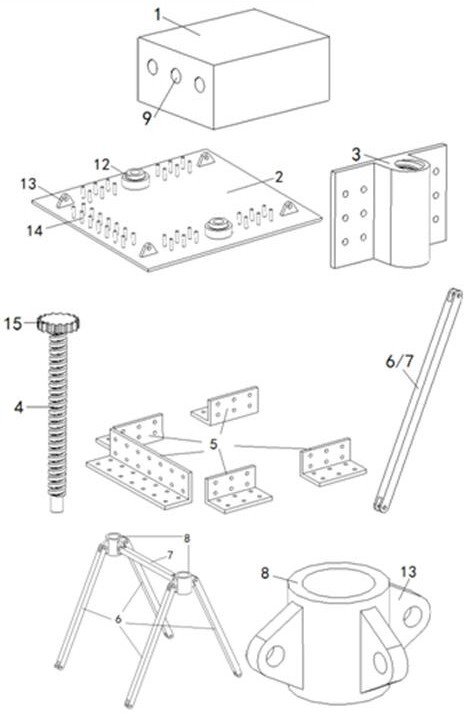

[0047] Below in conjunction with accompanying drawing, structure of the present invention and construction project are described in further detail.

[0048] Such as Figure 1-6 As shown, the present invention provides a bridge reinforcement system, which includes a movable steering block 1, a backing plate 2, an inner helical sleeve 3, a main screw 4, a connector 5, a longitudinal support rod 6, a transverse support rod 7, A smooth sleeve 8, the movable steering block is reserved with a steel beam steering channel 9, and the prestressed steel beam 10 passes through the steel beam steering channel and is anchored on the main beam 11 to be reinforced, and the backing plate is preset with a thrust bearing 12, Articulated joint 13 and screw rod 14, the top of main screw rod is welded with gear 15.

[0049]The movable steering block 1 contains a steel prestressed steering channel 9, and the other parts of the movable steering block are welded by steel plates, and holes need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com