Tantalum oxide coating both having good biocompatibility and photothermal conversion effects and preparation method and application of tantalum oxide coating

A technology of tantalum oxide and coating, applied in the field of tantalum oxide coating and its preparation, can solve the problem that the coating does not have the light-to-heat conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

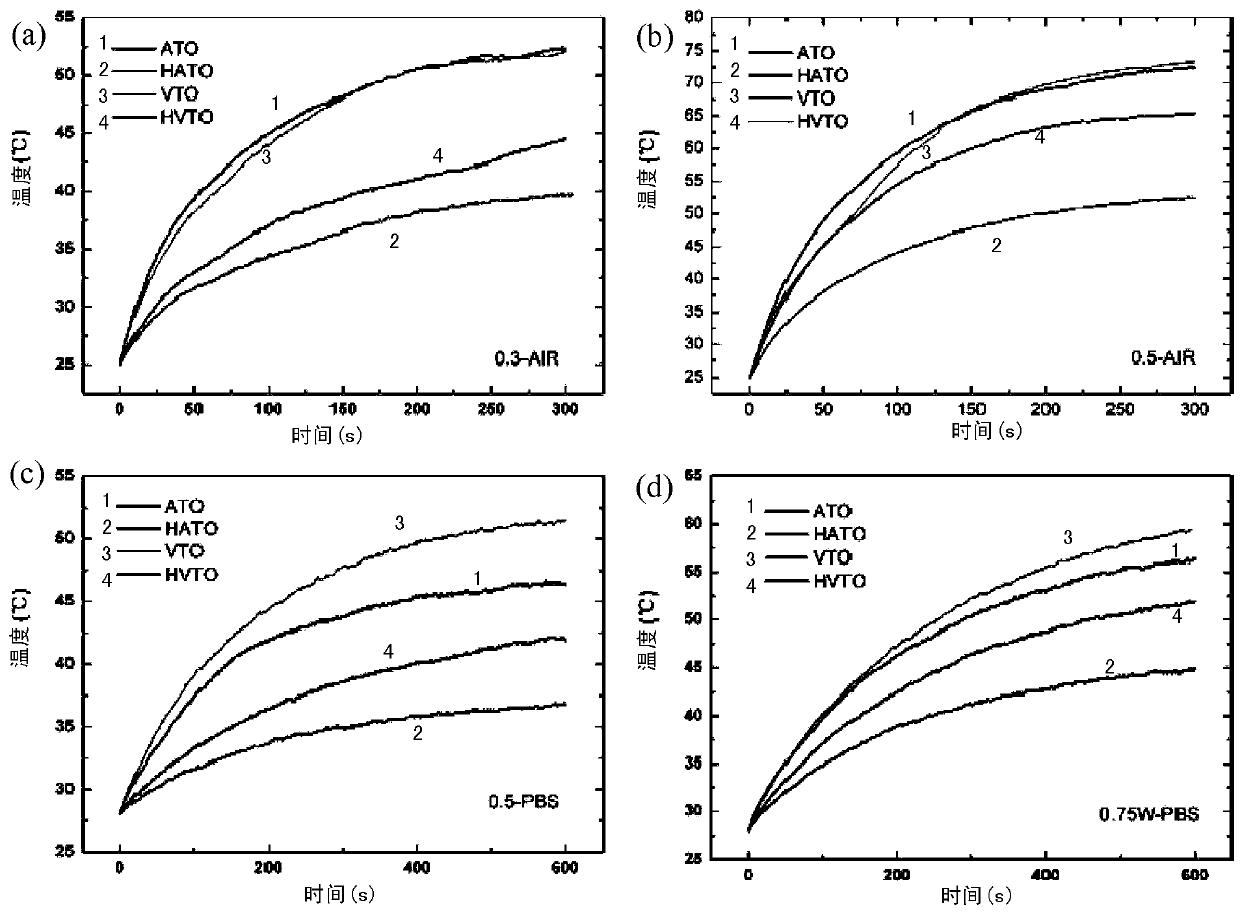

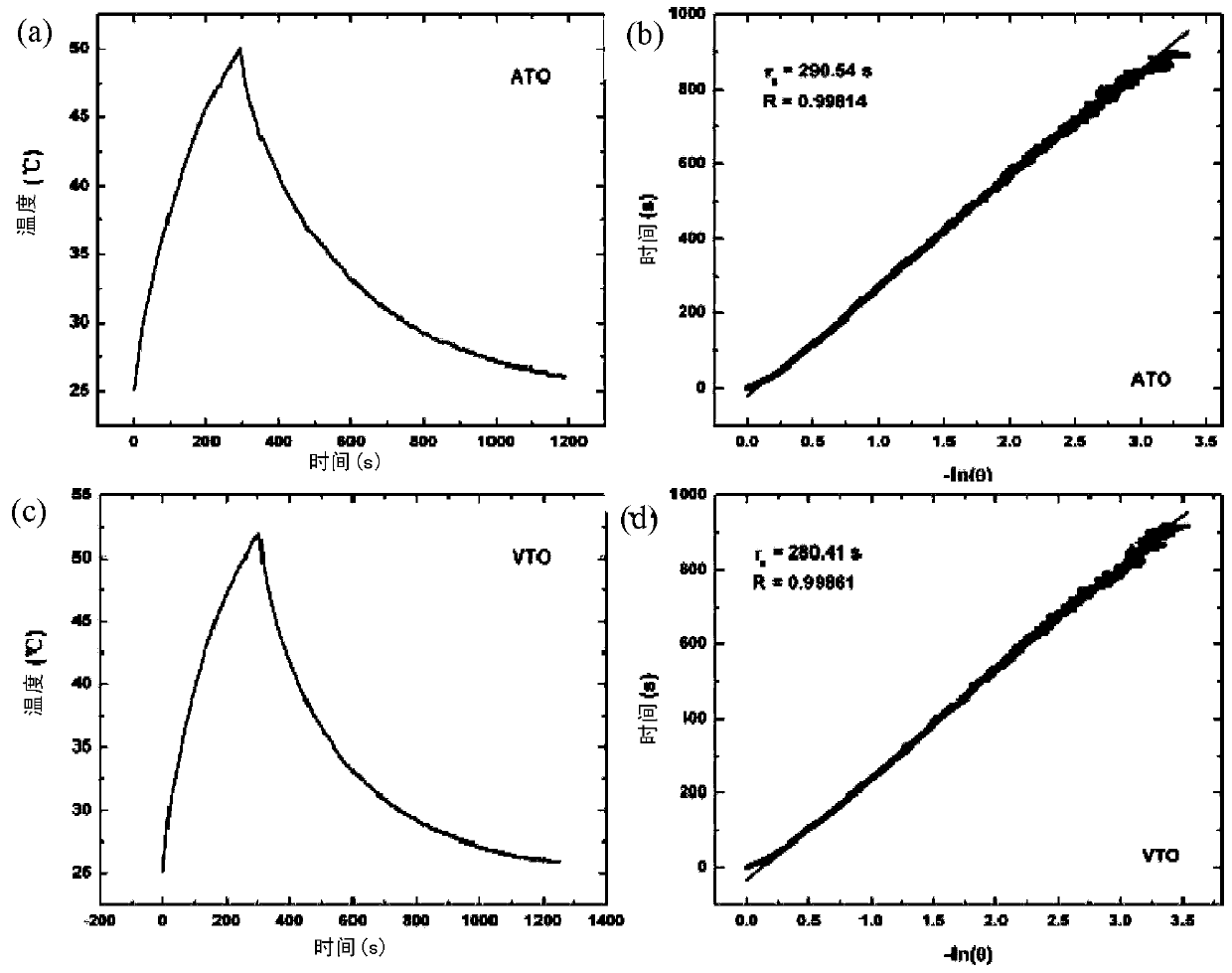

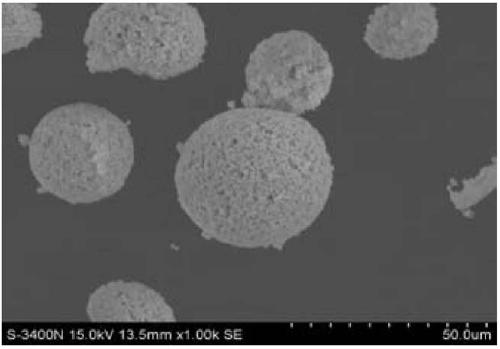

[0050] Choose Ta with a particle size of about 10 μm 2 o 5 Powder (w(Ta 2 o 5 )=99.99%) as raw material (purchased from Jiujiang Fengfu New Material Co., Ltd.), made into slurry with 40% solid content for spray granulation, atomizer speed: 22,000 rpm, feed rate: 770ML / points, the obtained powder morphology is as follows figure 1 shown. Depend on figure 1 It can be seen that most of the powder is in the shape of spherical particles with uniform size, about 20-80 μm, and has good fluidity. The powder was dried at 110°C for 1 hour, and cooled for later use.

[0051] The base material is made of titanium sheet, which is processed into a small disc of Φ10mm×2mm. After sandblasting the surface of the titanium sheet, ultrasonically clean it once in absolute ethanol solution for 3 minutes, then dry it at 100°C for 1 hour, and cool it for later use; the pressure of sandblasting is 0.3MPa.

[0052] Atmospheric plasma vacuum plasma spraying process is used respectively to spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com