Active protein nanoparticle prepared by restrictive enzymatic hydrolysis and preparation method and application thereof

A technology of active protein and nanoparticle, which is applied in the direction of nanotechnology, nanotechnology, nanomedicine, etc., can solve the problems of high equipment requirements, inability to use industrial scale production, organic solvent residues, etc., and achieve good industrialization prospects and excellent resistance Effects of oxidation activity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

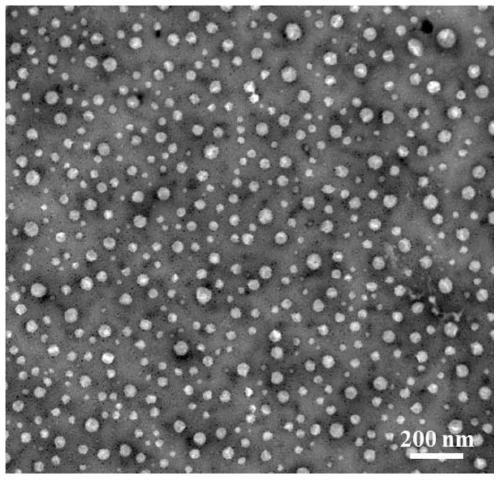

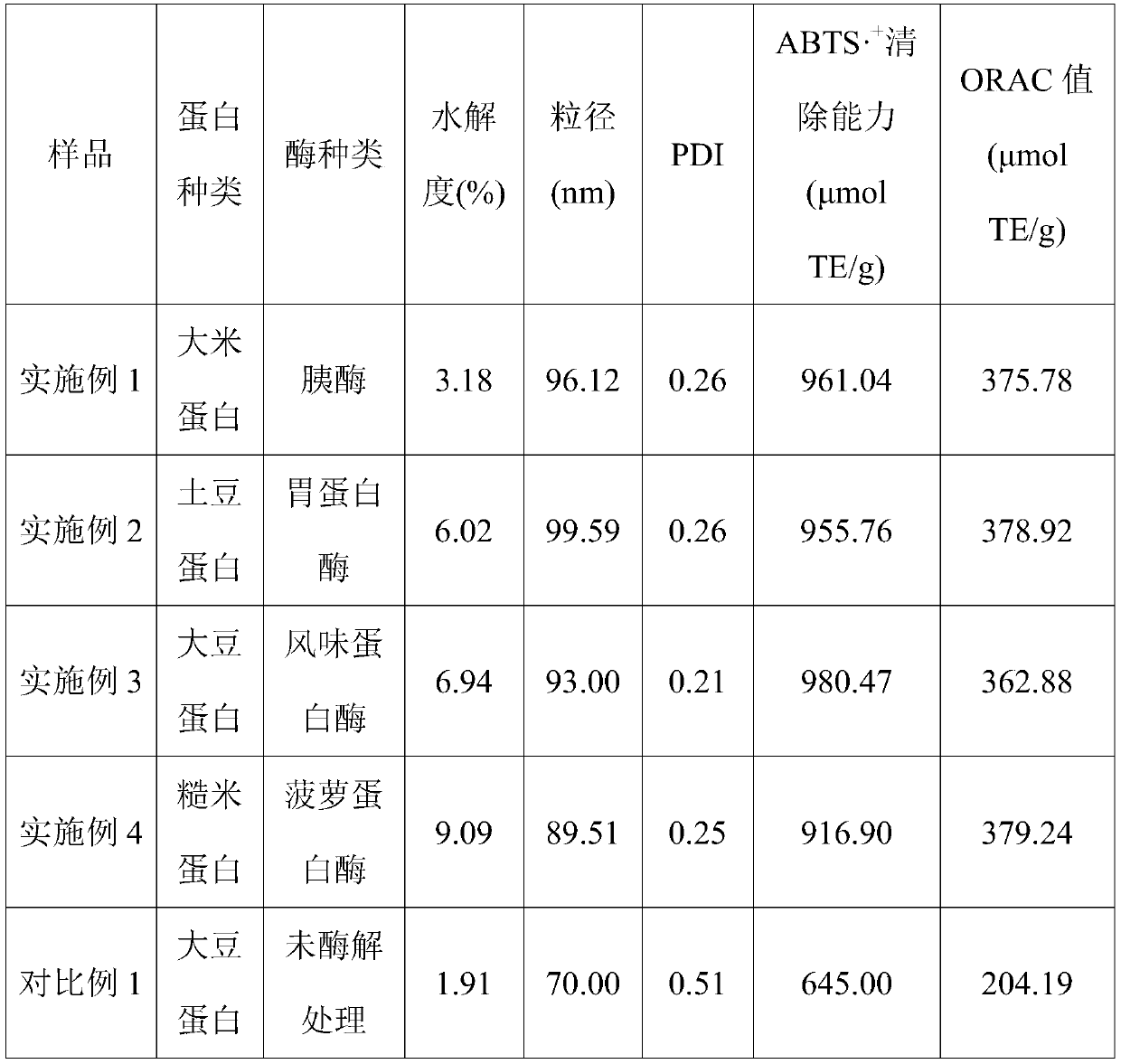

[0040]A method for preparing active protein nanoparticles by restricted enzymolysis provided in Example 1, comprising the following steps: mixing 0.5g of rice protein with 50mL of deionized water, stirring with a glass rod for 0.5h, and adjusting with 1mol / L sodium hydroxide solution pH to 8.5, adjust the temperature of the constant temperature oscillator to 35 degrees Celsius, adjust the rotation speed of the constant temperature oscillator to 140rpm, add trypsin at 0.05% of the rice protein mass under the state of stirring with a magnetic stirrer to carry out restricted enzymolysis, and the enzymolysis time is 1h , control the degree of proteolysis at 3%. After the enzymatic hydrolysis, adjust the pH to 6.0 with 1mol / L hydrochloric acid solution, adjust the temperature to 80 degrees Celsius, incubate for 15 minutes with a glass rod stirring at 100 rpm to inactivate the enzyme, centrifuge at 6000 rpm and 25 degrees Celsius for 20 minutes, and take the The serum was freeze-dri...

Embodiment 2

[0042] A method for preparing active protein nanoparticles by restricted enzymolysis provided in Example 2, comprising the following steps: mixing 4 g of potato protein with 100 mL of deionized water, stirring with a stirring paddle for 1 h, adjusting the pH to 1.5 with 2 mol / L hydrochloric acid solution, Adjust the temperature of the constant temperature incubator to 37 degrees Celsius, adjust the speed of the constant temperature incubator to 150rpm, add pepsin at 0.25% of the potato protein content under the state of stirring with a magnetic stirrer for restrictive enzymolysis, and the enzymatic hydrolysis time is 2h to control proteolysis degree at 6%. After the enzymolysis, adjust the pH to 7.0 with 2mol / L sodium hydroxide solution, adjust the temperature to 90 degrees Celsius, incubate for 10 minutes with the stirring paddle stirring at a rate of 120 rpm to inactivate the enzyme, and centrifuge at 8000 rpm and 15 degrees Celsius for 15 minutes. The supernatant was taken ...

Embodiment 3

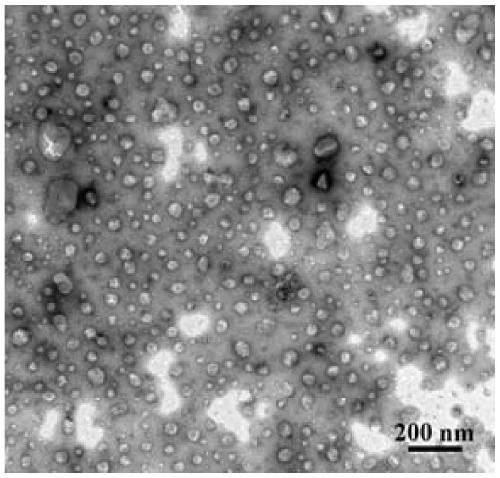

[0044] A method for preparing active protein nanoparticles by restricted enzymolysis provided in Example 3, comprising the following steps: mixing 12 g of soybean protein with 150 mL of deionized water, stirring with a magnetic stirrer for 2 h, and adjusting the pH with 3 mol / L sodium hydroxide solution to 7.0, adjust the temperature of the constant temperature oscillator to 50 degrees Celsius, adjust the speed of the constant temperature oscillator to 160rpm, and in the state of stirring with a magnetic stirrer, add flavor protease according to 0.5% of the protein amount for restriction enzymolysis, and the enzymatic hydrolysis time is 1.5h , control the degree of proteolysis at 7%. After enzymatic hydrolysis, adjust the pH to 7.5 with 3mol / L sodium hydroxide solution, adjust the temperature to 95 degrees Celsius, incubate for 10 minutes with a magnetic stirrer stirring at a rate of 130 rpm to inactivate the enzyme, and centrifuge at 10,000 rpm and 20 degrees Celsius for 8 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com