Visible light-cured adhesive and application thereof

An adhesive and visible light technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of high equipment cost, harsh curing conditions, high production cost, etc., and achieve low application cost and self-leveling Good effect and reduced application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

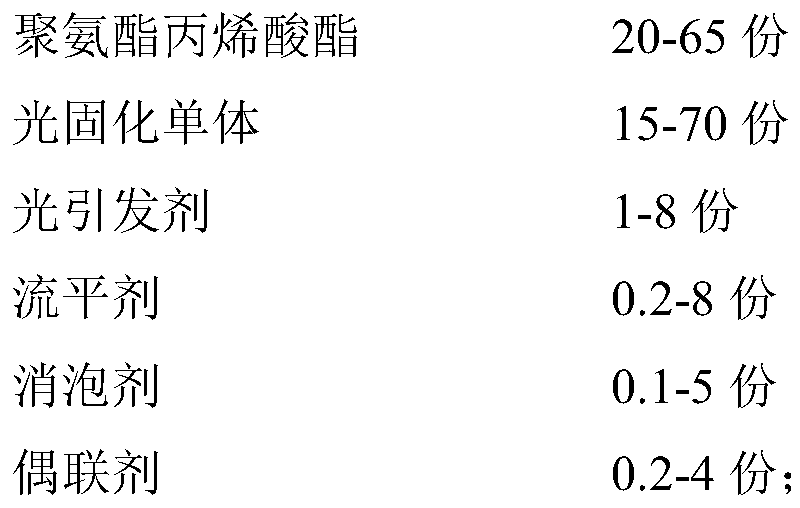

[0032] A visible light-curable adhesive, in parts by weight, comprising the following components:

[0033]

[0034] The functionality of the urethane acrylate is 2.

[0035] The photoinitiator is 2,4,6-trimethylbenzoyldiphenylphosphine oxide.

[0036] The photocurable monomer is 20 parts of tripropylene glycol acrylate and 27 parts of trimethylolpropane trimethacrylate.

[0037] A preparation method of visible light curing adhesive, comprising the following steps:

[0038] Stir and mix aliphatic urethane acrylate, photocurable monomer, photoinitiator, leveling agent, defoamer and silane coupling agent at 20° C. for 35 minutes to prepare the visible light curable adhesive.

[0039] A mobile phone screen, from top to bottom, sequentially includes a glass cover plate, the visible light curing adhesive and a display screen.

[0040] The preparation process of the mobile phone screen is as follows: wipe the display screen of the mobile phone clean with a cleaning cloth, drop ...

Embodiment 2

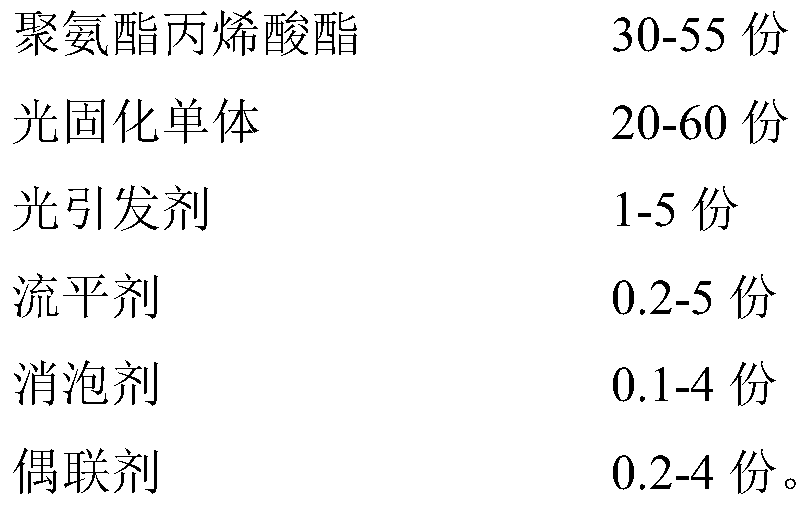

[0042] A visible light-curable adhesive, in parts by weight, comprising the following components:

[0043]

[0044] The functionality of the urethane acrylate is 3.

[0045] A preparation method of visible light curing adhesive, comprising the following steps:

[0046] Stir and mix aliphatic urethane acrylate, photocurable monomer, photoinitiator, leveling agent, defoamer and silane coupling agent at 30° C. for 40 minutes to prepare the visible light curable adhesive.

[0047] A mobile phone screen, from top to bottom, sequentially includes a glass cover plate, the visible light curing adhesive and a display screen.

[0048] The preparation process of the mobile phone screen is as follows: wipe the display screen of the mobile phone clean with a cleaning cloth, drop the visible light-curable adhesive to the middle of the display screen surface, the amount of visible light-curable adhesive is 5ml, and then gently put the glass cover on until The visible light-curable adhes...

Embodiment 3

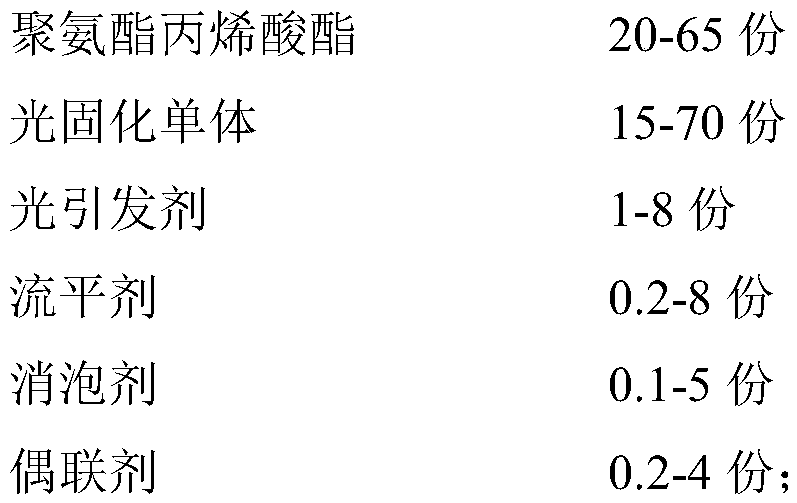

[0050] A visible light-curable adhesive, in parts by weight, comprising the following components:

[0051]

[0052]

[0053] The photoinitiator is 0.5 part of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, and 0.5 part of aminophosphoramide acrylate.

[0054] The photocurable monomer is 10 parts of acryloylmorpholine, 5 parts of lauryl methacrylate, and 5 parts of polyethylene glycol diacrylate.

[0055] A preparation method of visible light curing adhesive, comprising the following steps:

[0056] Stir and mix polyurethane acrylate, photocurable monomer, photoinitiator, leveling agent, defoamer and silane coupling agent at 15°C for 40 minutes to prepare the visible light curable adhesive.

[0057] A mobile phone screen, from top to bottom, sequentially includes a glass cover plate, the visible light curing adhesive and a display screen.

[0058]The visible light-curable adhesive is applied between the display screen and the glass cover to better protect the display s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com