A benzene-free imaging layer for dark laser anodized aluminum and its preparation method

An imaging layer, anodized aluminum technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as narrow hot stamping limitations, poor bonding fastness between color layers and aluminum layers, and poor coating leveling appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

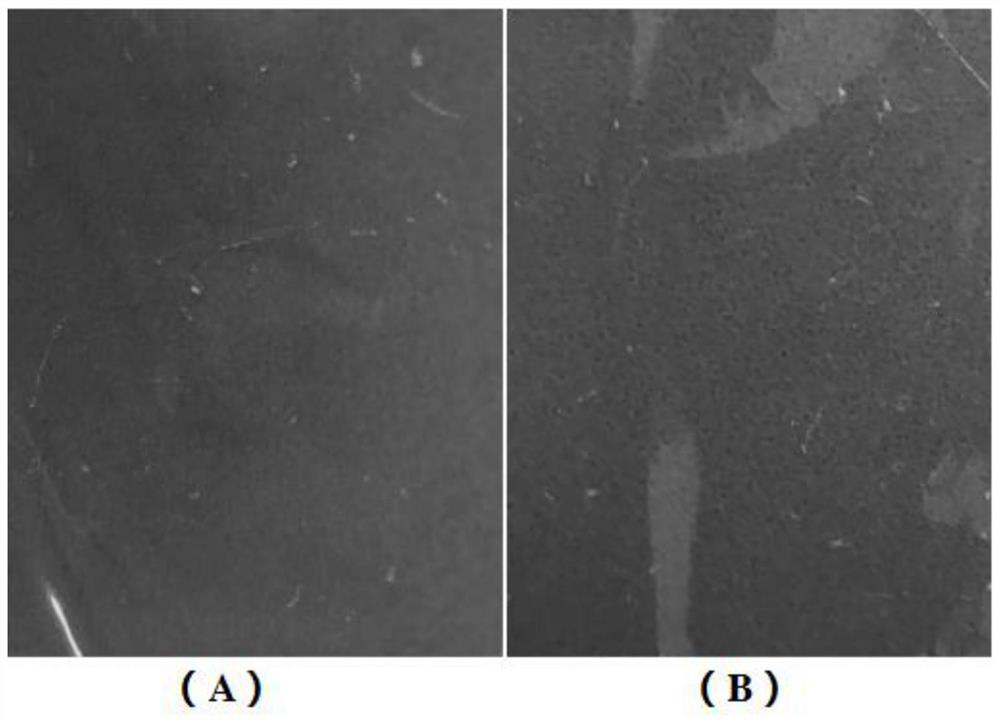

Image

Examples

preparation example Construction

[0031] Embodiments of the present invention also provide a method for preparing a benzene-free imaging layer for dark laser anodized aluminum, comprising the following steps:

[0032] (1) prepare materials by weight;

[0033] (2) After dissolving the acrylic resin, auxiliary resin, film-forming agent, leveling agent and defoamer, mix them uniformly to obtain a resin solution; then mix the resin solution and toner solution uniformly to obtain a finished product.

[0034] The benzene-free imaging layer prepared in the present invention can adjust the solid content of the finished product according to actual usage requirements.

Embodiment 1

[0038] Embodiment 1 of the present invention provides a benzene-free imaging layer for dark laser anodized aluminum, comprising the following components by weight: 22 parts of methyl methacrylate copolymer, 3.2 parts of aliphatic urethane acrylate, ethylene - 3 parts of vinyl acetate copolymer, 2.4 parts of cellulose acetate butyrate, 0.3 parts of acrylate copolymer, 0.1 part of polyvinyl ether, 0.2 part of acrylate polymer and 4 parts of C.I. pigment 80.

[0039] The benzene-free imaging layer is prepared by the following method:

[0040] (1) Add methyl methacrylate copolymer, aliphatic urethane acrylate, ethylene-vinyl acetate copolymer, cellulose acetate butyrate, acrylate copolymer, polyvinyl ether and acrylate polymer to n-propyl acetate In the mixed solvent of ester and butanone (the volume ratio of n-propyl acetate and butanone is 1:2), stir at 500r / min for 40min until several substances are fully mixed and evenly, to obtain a resin solution;

[0041] (2) Add C.I. Pigm...

Embodiment 2

[0044]Embodiment 2 of the present invention provides a benzene-free imaging layer for dark laser anodized aluminum, comprising the following components by weight: 24 parts of methacrylic acid copolymer, 3.2 parts of aliphatic urethane acrylate, acrylic polyol 4.5 parts of resin, 4 parts of ethylene-vinyl acetate copolymer, 3 parts of cellulose acetate butyrate, 0.4 part of acrylate copolymer, 0.2 part of polyvinyl ether, 0.2 part of acrylate polymer and 805 parts of C.I. Pigment Blue.

[0045] The preparation method of this benzene-free imaging layer is the same as the preparation method in Example 1, the difference is that step (1) is: copolymerizing methacrylic acid copolymer, aliphatic urethane acrylate, acrylic polyol resin, ethylene-vinyl acetate copolymer Add cellulose acetate butyrate, acrylate copolymer, polyvinyl ether and acrylate polymer to the mixed solvent of n-propyl acetate and butanone (the volume ratio of n-propyl acetate and butanone is 1:2) , and stirred at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com