Method for preparing cordierite porous ceramic material by using waste catalyst

A technology for waste catalysts and porous ceramics, which is applied in the field of solid waste resource utilization, can solve problems such as the difficulty of treatment of industrial waste catalysts, and achieve the effects of improving sintering, reducing thermal expansion coefficient and improving thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

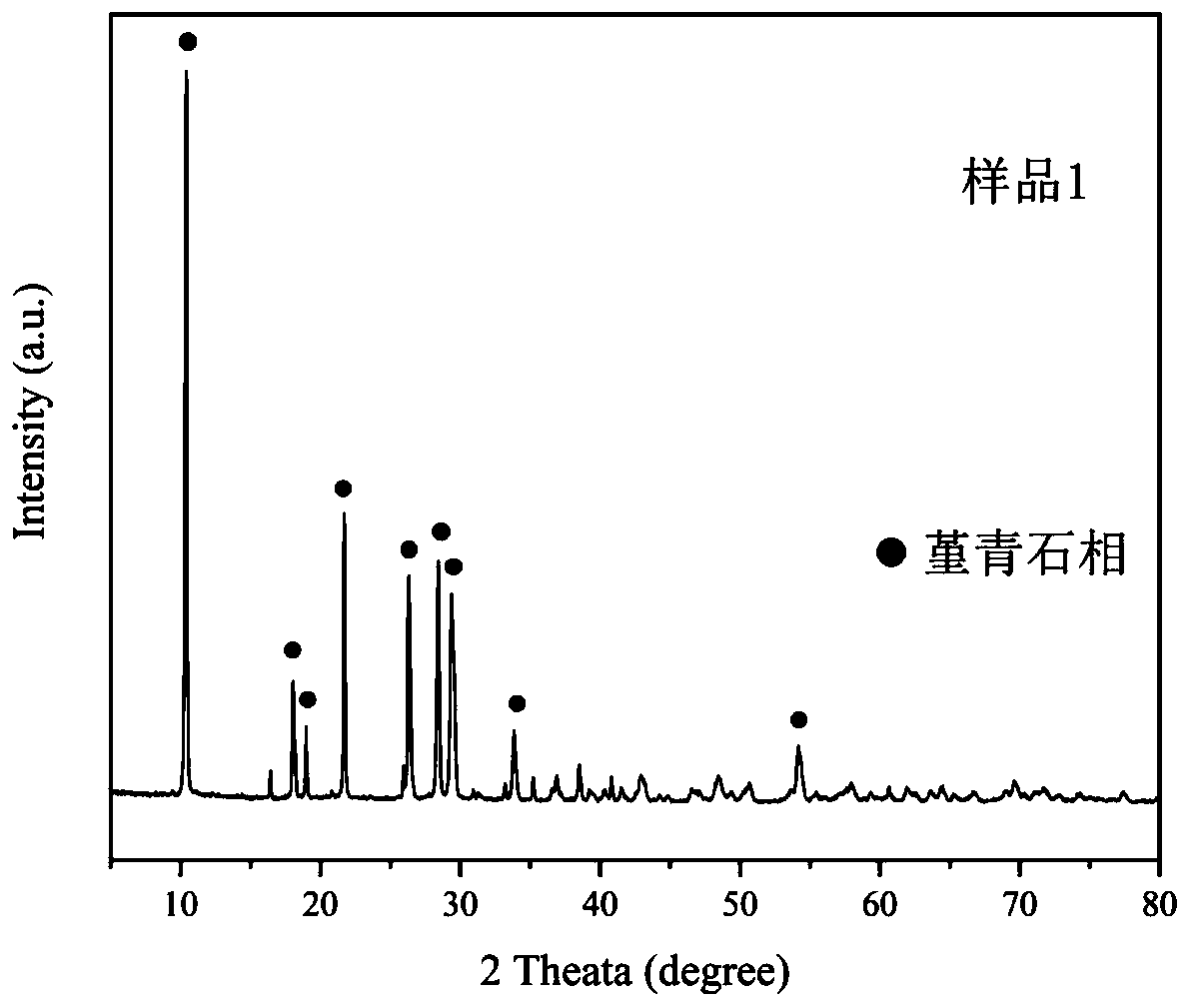

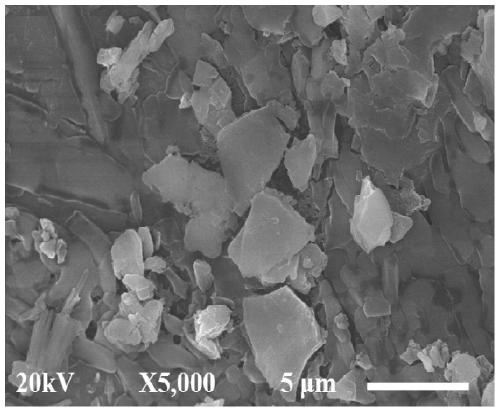

Embodiment 1

[0045] A method for preparing a cordierite porous ceramic material by using waste catalysts, the raw material components and parts by weight are: 60 parts of waste molecular sieve catalysts; 40 parts of waste hydrotalcite catalysts.

[0046] The above synthetic method for preparing the cordierite porous ceramic material by using the waste catalyst, the specific steps are as follows:

[0047] (1) According to the composition of the raw material formula, the raw material is crushed, dried at 80°C for 12 hours, and wet ball milled for 4 hours to obtain a slurry, wherein raw material: ball: water = 1:1.5:1;

[0048] (2) The slurry is filtered, aged for 24 hours, dried at 80°C for 12 hours, ground and passed through a 120-mesh sieve to obtain a powder;

[0049] (3) After the powder is uniformly mixed with 5% polyvinyl alcohol binder, it is molded under 20MPa pressure, and dried at 80°C for 12 hours to obtain a molded embryo;

[0050] (4) Place the embryo body in a high-temperature...

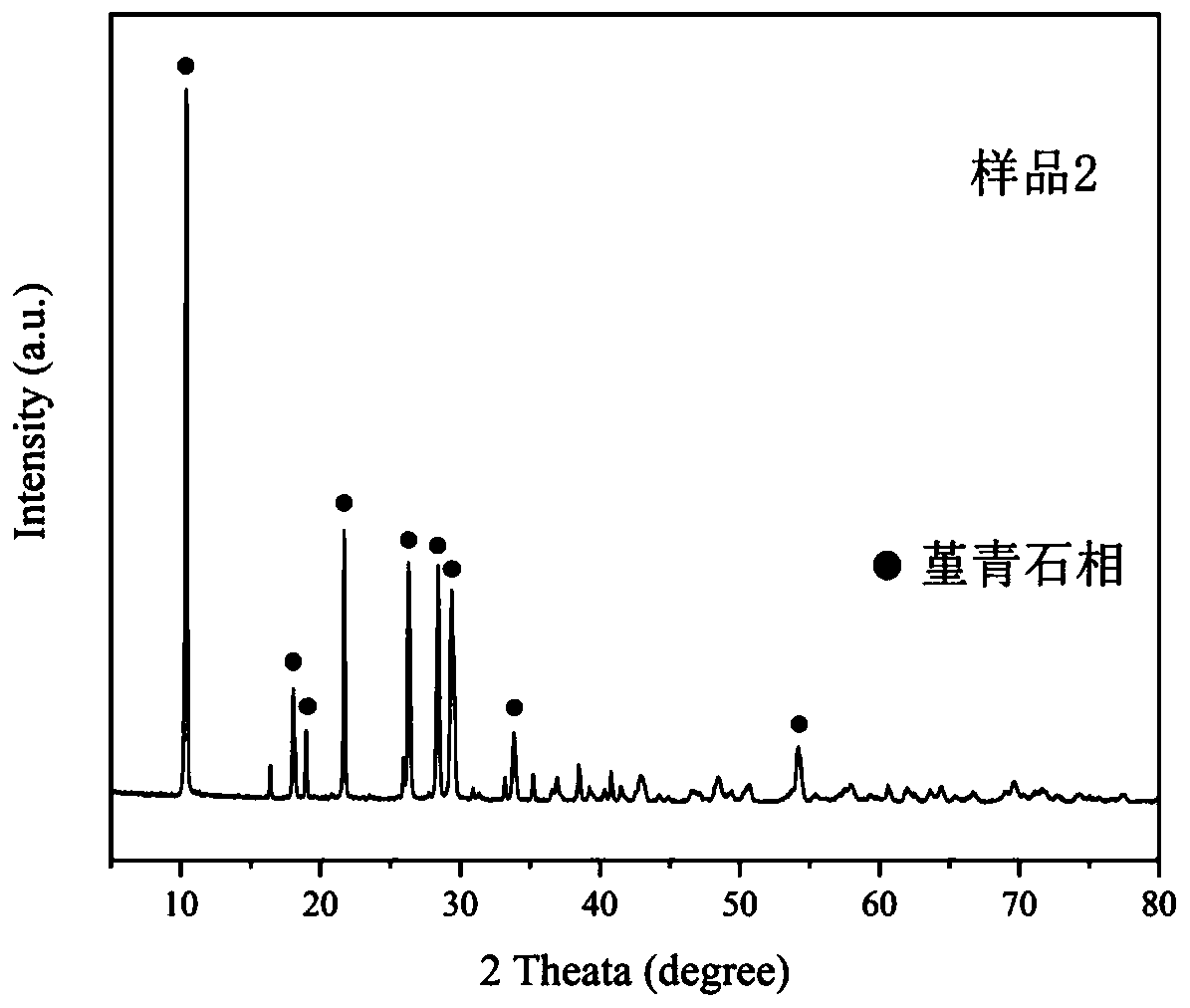

Embodiment 2

[0052] A method for preparing a cordierite porous ceramic material by using waste catalysts, the raw material components and parts by weight are: 60 parts of waste molecular sieve catalysts; 40 parts of waste hydrotalcite catalysts.

[0053] The above synthetic method for preparing the cordierite porous ceramic material by using the waste catalyst, the specific steps are as follows:

[0054] (1) Pre-burn raw materials, put the waste catalyst into a high-temperature furnace to raise the temperature to 700 °C at a rate of 100 °C / h, keep it warm for 2 hours, and then drop it to room temperature at a rate of -150 °C / h to obtain pre-calcined raw materials .

[0055] (2) According to the composition of the raw material formula, the raw material is crushed, dried at 80°C for 12 hours, and wet ball milled for 4 hours to obtain a slurry, wherein raw material: ball: water = 1:1.5:1;

[0056] (3) The slurry is filtered, aged for 24 hours, dried at 80°C for 12 hours, ground and passed th...

Embodiment 3

[0060] A method for preparing a cordierite porous ceramic material by using waste catalysts. The raw material components and parts by weight are as follows: 60 parts of waste molecular sieve catalysts; 40 parts of original hydrotalcite catalysts modified without adding zirconia.

[0061] The above synthetic method for preparing the cordierite porous ceramic material by using the waste catalyst, the specific steps are as follows:

[0062] (1) According to the composition of the raw material formula, the raw material is crushed, dried at 80°C for 12 hours, and wet ball milled for 4 hours to obtain a slurry, wherein raw material: ball: water = 1:1.5:1;

[0063] (2) The slurry is filtered, aged for 24 hours, dried at 80°C for 12 hours, ground and passed through a 120-mesh sieve to obtain a powder;

[0064] (3) After the powder is uniformly mixed with 5% polyvinyl alcohol binder, it is molded under 20MPa pressure, and dried at 80°C for 12 hours to obtain a molded embryo;

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com