Low Si/Al ratio ZSM-48 molecular sieve preparation method

A technology of molecular sieves and cations, applied in molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of not being suitable for industrialization, limiting the wide application of catalytic reactions, and being difficult for industrial scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the preparation method of the ZSM-48 molecular sieve of a kind of low Si / Al ratio provided by the present invention comprises the following steps:

[0031] In the first step, the silicon source, the alkali source and water are mixed to make OH in the resulting mixed solution 1 - / SiO 2 The ratio is between 0.01-1.0;

[0032] In the second step, the mixed solution 1 is mixed with a structure-directing agent (Structure-Directing Agent, SDA) to obtain a mixed solution 2;

[0033] The third step is to mix the mixed solution 2 with the aluminum source to obtain a precursor gel;

[0034] In the fourth step, the precursor gel is subjected to hydrothermal crystallization to obtain a sample (mixture);

[0035] The fifth step is to process the sample to obtain ZSM-48 molecular sieve.

[0036] The structure of the structure directing agent used in the preparation method provided by the present invention is shown in formula I,

[0037] (CH 3 ) 3 N + RX -

[...

Embodiment 1

[0061] Preparation of ZSM-48 molecular sieve M1

[0062] (1) Weigh 4.00g of sodium silicate, 0.56g of sodium hydroxide and 35.80g of secondary deionized water and stir evenly at room temperature, add 0.79g of H 2 SO 4 Adjust OH - / SiO 2 is 0.2;

[0063] (2) add 5.74g allyltrimethylammonium chloride in the solution of step (1) gained, stir again;

[0064] (3) Add 0.12g aluminum nitrate to the solution obtained in step (2), stir to form a homogeneous solution, wherein the mol ratio of each component is SiO 2 :Al 2 o 3 : Na 2 O: SDA: OH - :H 2 O=1:0.005:0.4:1:0.2:60;

[0065] (4) Transfer the obtained solution to a 100 mL hydrothermal kettle. Dynamic hydrothermal crystallization at 160°C for 24 hours;

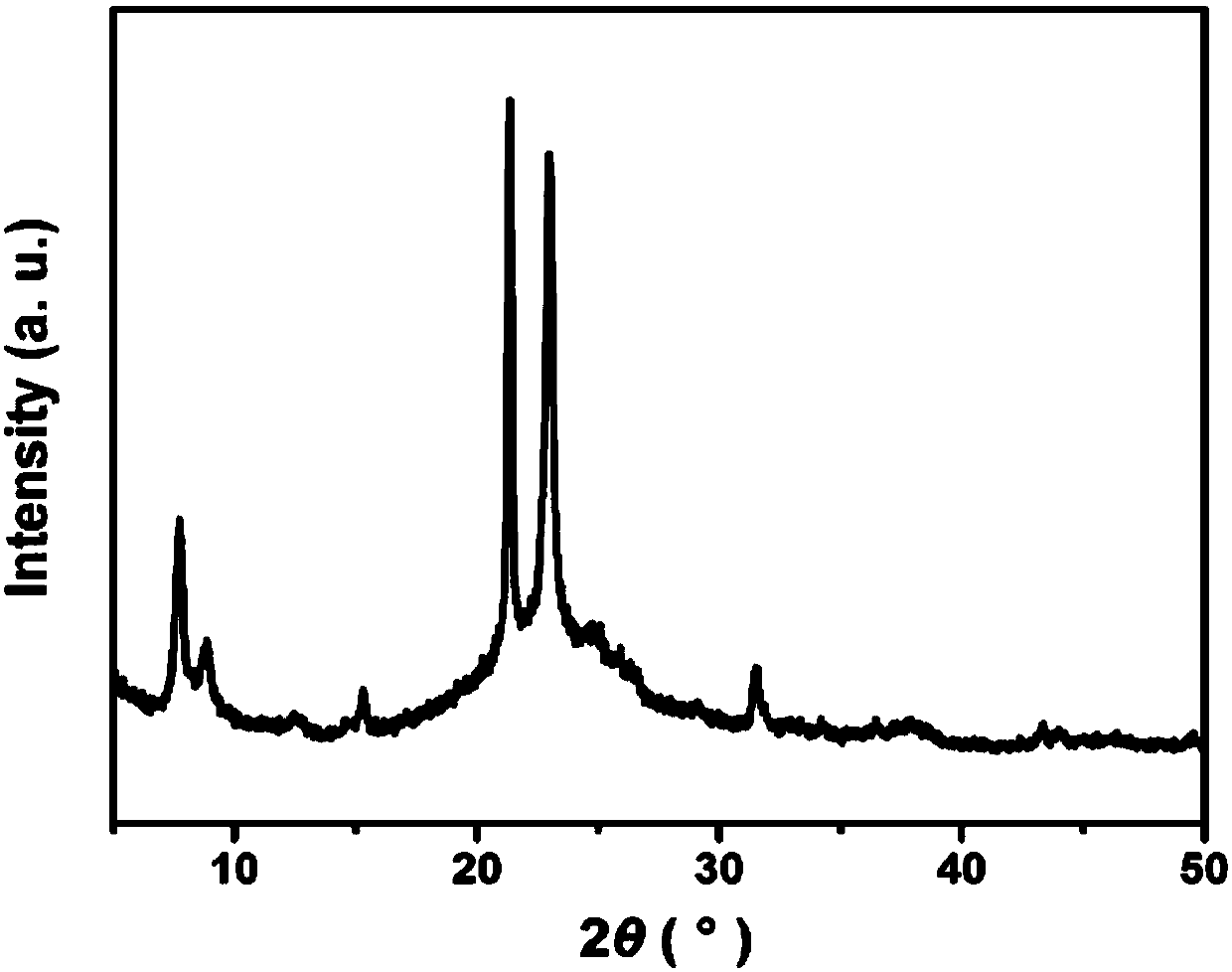

[0066] (5) The mixture obtained in (4) was centrifuged, washed, and dried to obtain a molecular sieve powder M1 with a Si / Al ratio of 100, which was ZSM-48 molecular sieve by XRD analysis. Calcined at 600° C. for 10 h in an air atmosphere to obtain the final ZSM-48 mo...

Embodiment 2

[0068] Preparation of ZSM-48 molecular sieve M2

[0069] (1) Weigh 3.50g of sodium silicate, 0.39g of sodium hydroxide and 29.80g of secondary deionized water and stir evenly at room temperature, add 0.63g of H 2 SO 4 Adjust OH - / SiO 2 is 0.2;

[0070] (2) add 4.49g allyltrimethylammonium chloride in the solution of step (1) gained, stir again;

[0071] (3) Add 0.21g aluminum nitrate to the solution obtained in step (2), stir to form a homogeneous solution, wherein the molar ratio of each component is SiO 2 :Al 2 o 3 : Na 2 O: SDA: OH - :H 2 O=1:0.01:0.4:1:0.2:60;

[0072] (4) Transfer the obtained solution to a 100 mL hydrothermal kettle. Dynamic hydrothermal crystallization at 160°C for 48 hours;

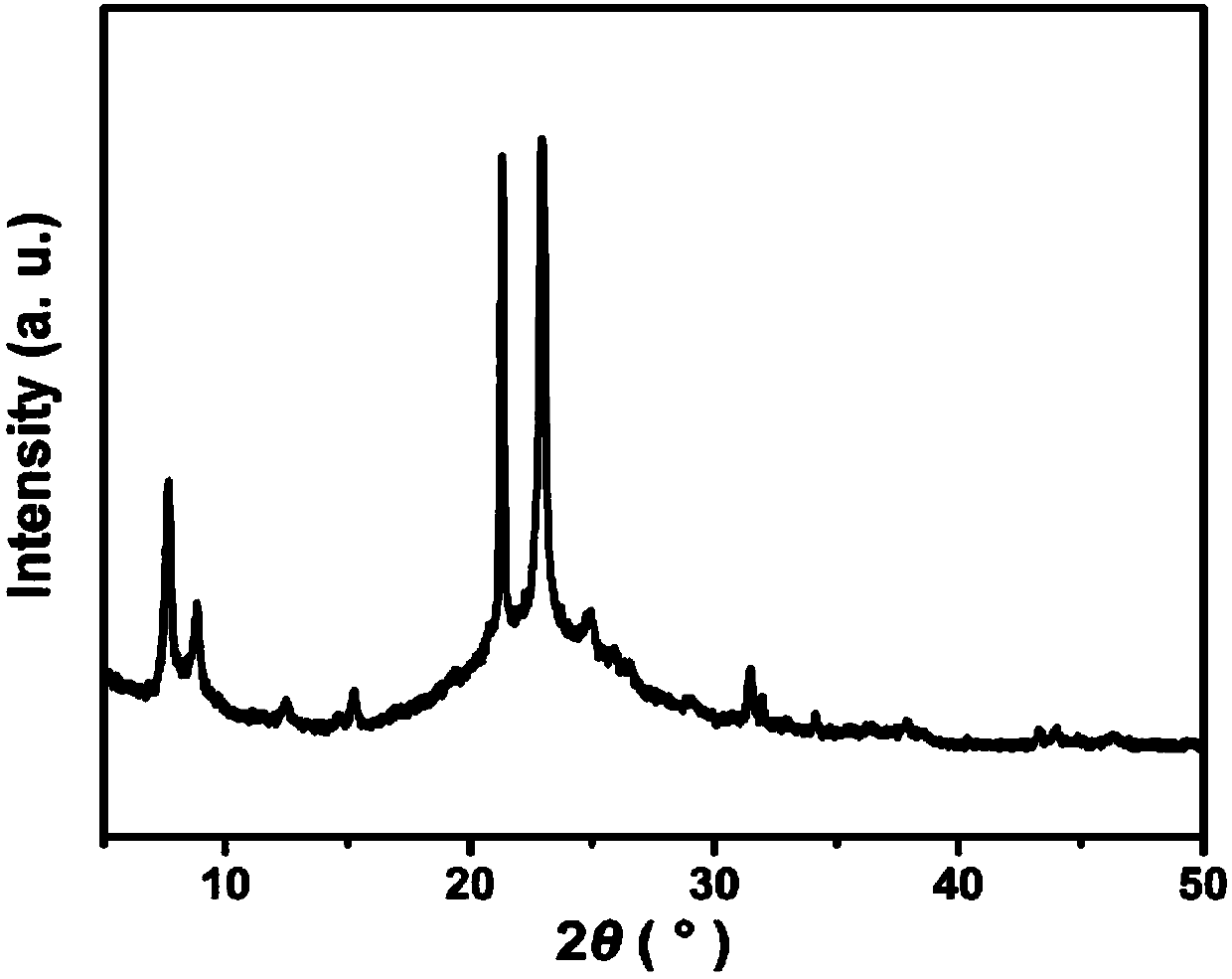

[0073] (5) The mixture obtained in (4) was centrifuged, washed, and dried to obtain a molecular sieve powder M2 with a Si / Al ratio of 50, which was ZSM-48 molecular sieve by XRD analysis. Calcined at 600° C. for 10 h in an air atmosphere to obtain the final ZSM-48 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com