Preparation method of modified graphene oxide material

A graphene and modification technology, which is applied in the field of preparation of modified graphene oxide materials, achieves the effects of simple preparation methods and equipment, accelerated doping reactions, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

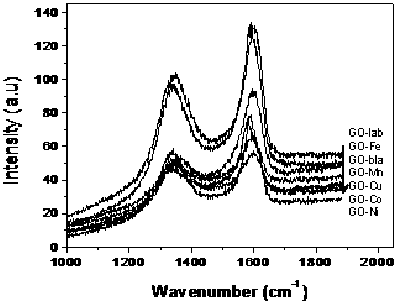

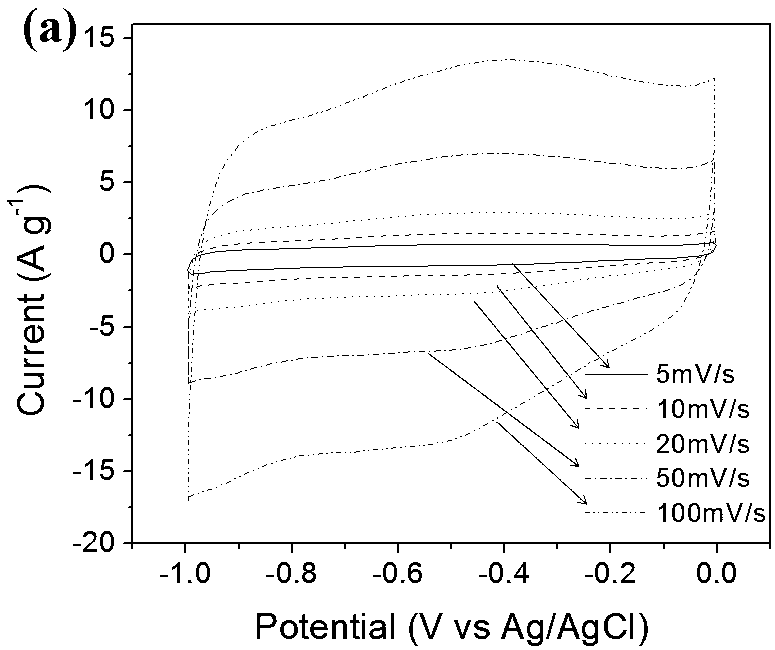

[0034] Put 1 g of graphite powder and 23 mL of concentrated sulfuric acid (98% by mass) in a round bottom flask and stir for 5 min under an ice-water bath. Then, in an ice-water bath, 5 g of potassium permanganate was continuously added to the slurry for 2 hours while stirring. After the potassium permanganate was added, the slurry was stirred for 3 hours at room temperature, and then the mixture was aged at room temperature for 12 hours. After 12 hours, wash the mixed solution with deionized water to neutrality, then place the mixed solution obtained in the step in a closed container, pass high-temperature steam to pressurize to 1.5-2.5Mpa, keep the pressure for 3-5min, and then pressurize at 87.5 The pressure is released to normal pressure by flash opening the end cap of the closed container within a millisecond, and the material is sprayed into the collection bin with the steam; the collected product is constant volume, and a well-dispersed graphene oxide solution is obtaine...

Embodiment 2

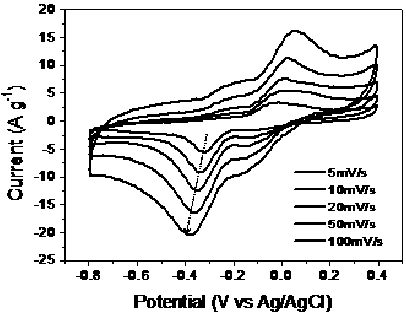

[0036]Put 1 g of graphite powder and 23 mL of concentrated sulfuric acid (98% by mass) in a round bottom flask and stir for 5 min under an ice-water bath. Then, in an ice-water bath, 5 g of potassium permanganate was continuously added to the slurry for 2 hours while stirring. After the potassium permanganate was added, the slurry was stirred for 1 hour at room temperature, and then the mixture was aged at room temperature for 6 hours. Afterwards, the mixture was washed to neutral with deionized water, and then 0.08 g of CoCl was added to the solid slurry 2 • 6H2O, stir well. Then mix the mixed solution obtained in the step with the Co salt solution, stir evenly and place it in an airtight container, seal the airtight container, pass high-temperature steam to pressurize to 1.0-2.0Mpa, and keep the pressure reaction for 3-5min, Then release the pressure to normal pressure by flashing the end cap of the closed container within 87.5 milliseconds, and the material is sprayed into...

Embodiment 3

[0038] Put 1 g of graphite powder and 23 mL of concentrated sulfuric acid (98% by mass) in a round bottom flask and stir for 5 min under an ice-water bath. Then, in an ice-water bath, 5 g of potassium permanganate was continuously added to the slurry for 2 hours while stirring. After the addition of potassium permanganate was complete, the slurry was stirred at room temperature for 6 hours, and then the mixture was aged at room temperature for 18 hours. Afterwards, the mixture was washed to neutral with deionized water, and then 0.08 g of NiCl was added to the solid slurry 2 • 6H2O, stir well. Then mix the mixed solution obtained in the step with the Ni salt solution, stir evenly, and place it in a closed container, seal the closed container, pass high-temperature steam to pressurize to 1.5-2.5Mpa, and keep the pressure reaction for 1-3min, Then release the pressure to normal pressure by flashing the end cap of the closed container within 87.5 milliseconds, and the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com